Grinding machine for novel macromolecular jade production

A polymer and grinding machine technology, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problems that jade is not suitable for mass production and high cost, and achieve improved grinding efficiency and improved Work efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

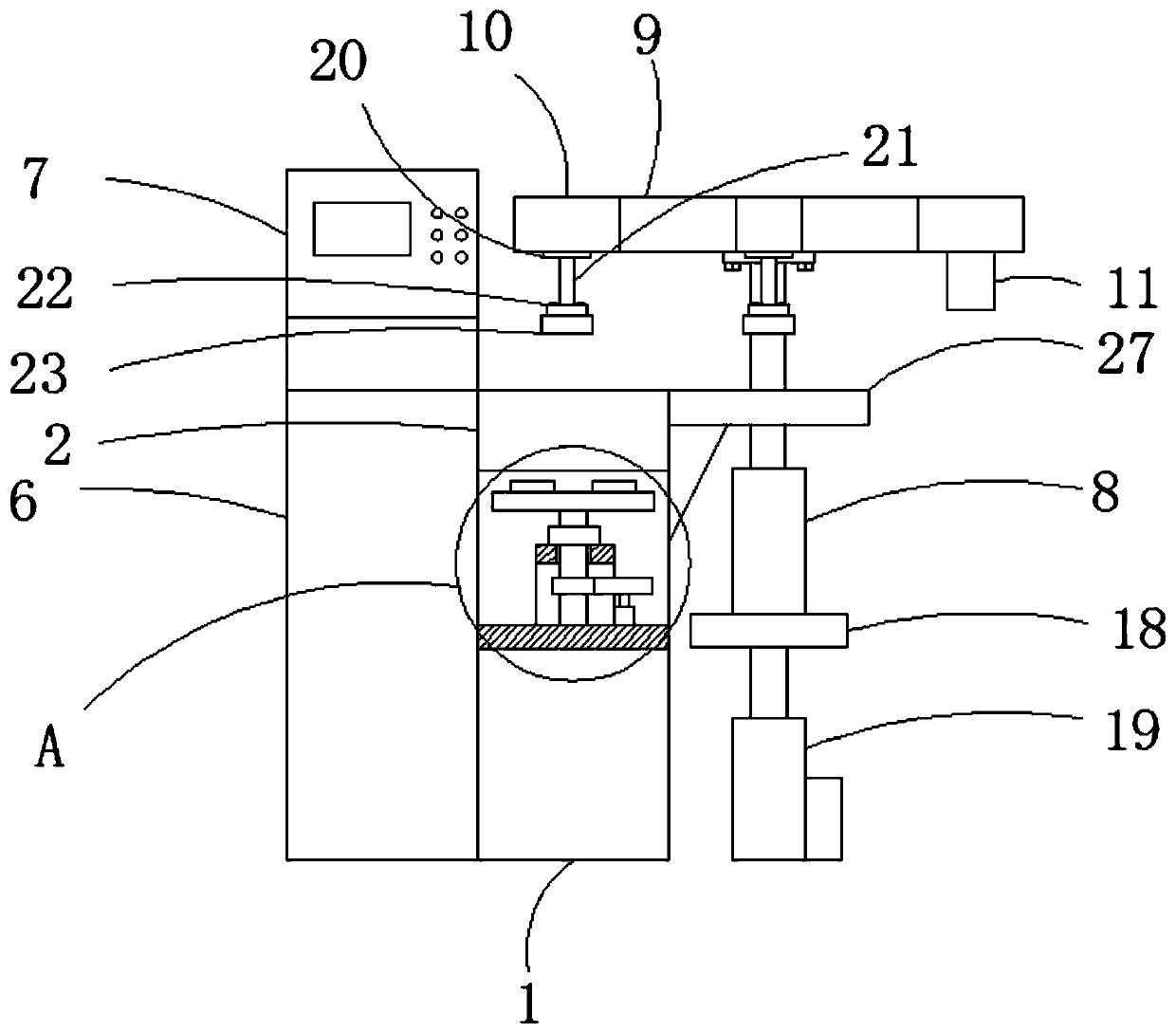

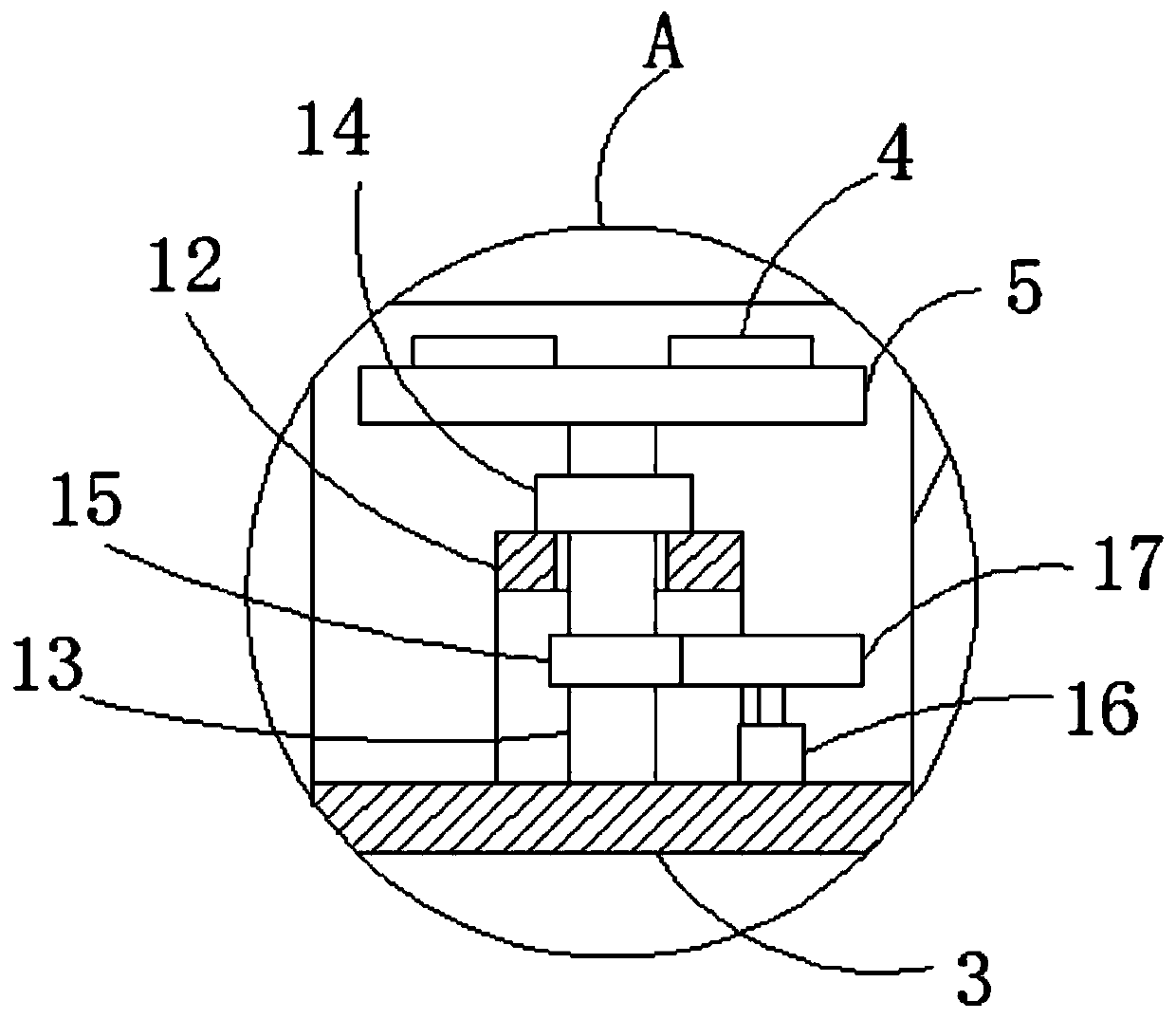

[0026] see Figure 1-3 , a new type of polymer jade grinding machine, including a work cabinet 1, the top of the work cabinet 1 is fixed with a grinding tank 2, the inside of the work cabinet 1 is equipped with a magnetic mechanism, the inside of the work cabinet 1 Connected with a support plate 3, the magnetic mechanism is installed on the support plate 3, the magnetic mechanism includes an electromagnetic coil 4, a first mounting plate 5, a rotating mechanism and a driving mechanism, and the electromagnetic coil 4 is fixedly installed on the first mounting plate 5, the bottom end of the first mounting plate 5 is fixedly connected to the output end of the rotating mechanism, and the rotating mechanism is driven by a driving mechanism; an industrial control cabinet 6 is installed on one side of the working cabinet 1, and the industrial control cabinet 6 An operation panel 7 is fixedly installed on the top of the work cabinet 1, and a refueling mechanism is provided on the side...

Embodiment 2

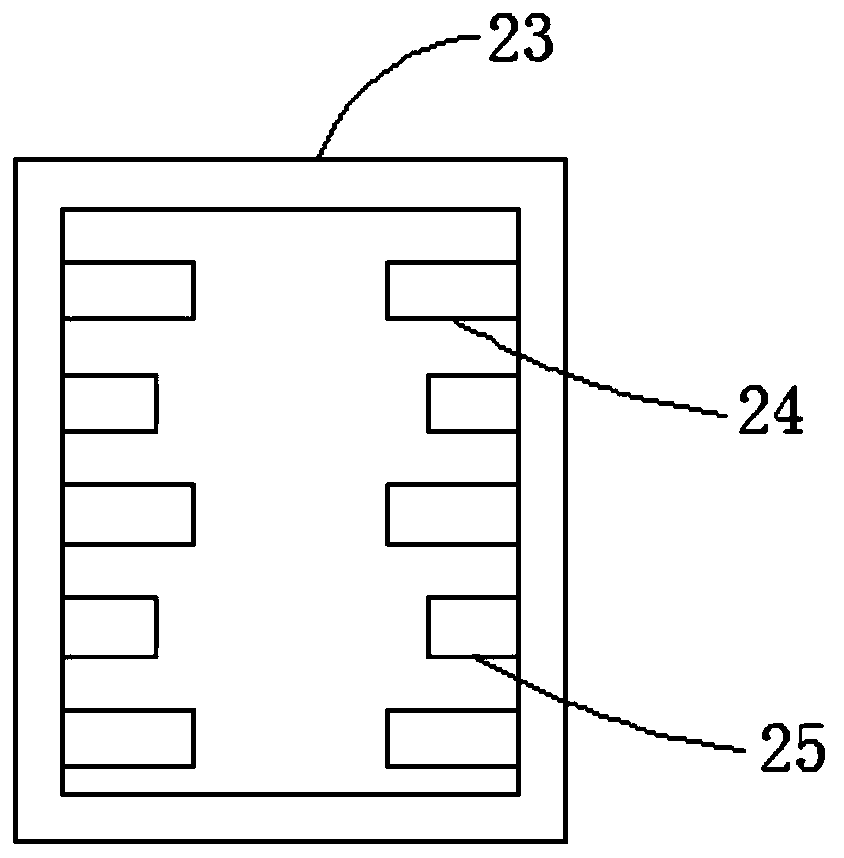

[0034] Please refer to Figure 4Compared with the first embodiment, this embodiment is different in that reinforcement holes are provided on the outer walls of the first reinforcement board 24 and the second reinforcement board 25, and the first reinforcement board 24 and the second reinforcement board 25 The outer wall is fixedly connected with protrusions 26. When the liquid fixing glue is filled in the clamping groove, the first reinforcement plate 24 and the second reinforcement plate 25 with reinforcement holes and protrusions 26 can be better when the fixing glue is solidified. It plays the role of pulling glue to prevent the solidified fixing glue from detaching from the clamping groove.

[0035] The side of the grinding tank 2 close to the rotary cylinder 8 is fixedly connected with a worktable 27, and the piston end of the rotary cylinder 8 runs through the worktable 27, and is rotatably connected with the worktable 27 through a bearing.

[0036] To sum up, when in u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com