A flux and process for laser welding thermoformed steel

A technology of hot forming steel and laser welding, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of damaging other properties of products, and achieve improved weldability, increased plasticity and toughness, and less environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method of the present invention is further specifically described by the examples given below.

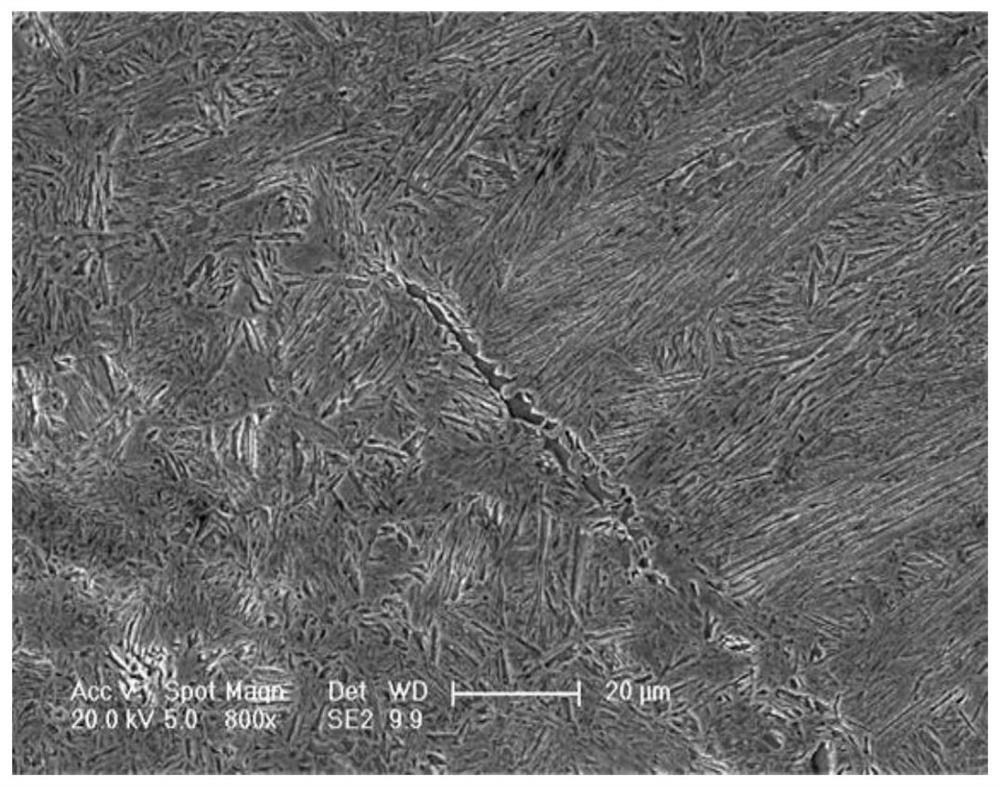

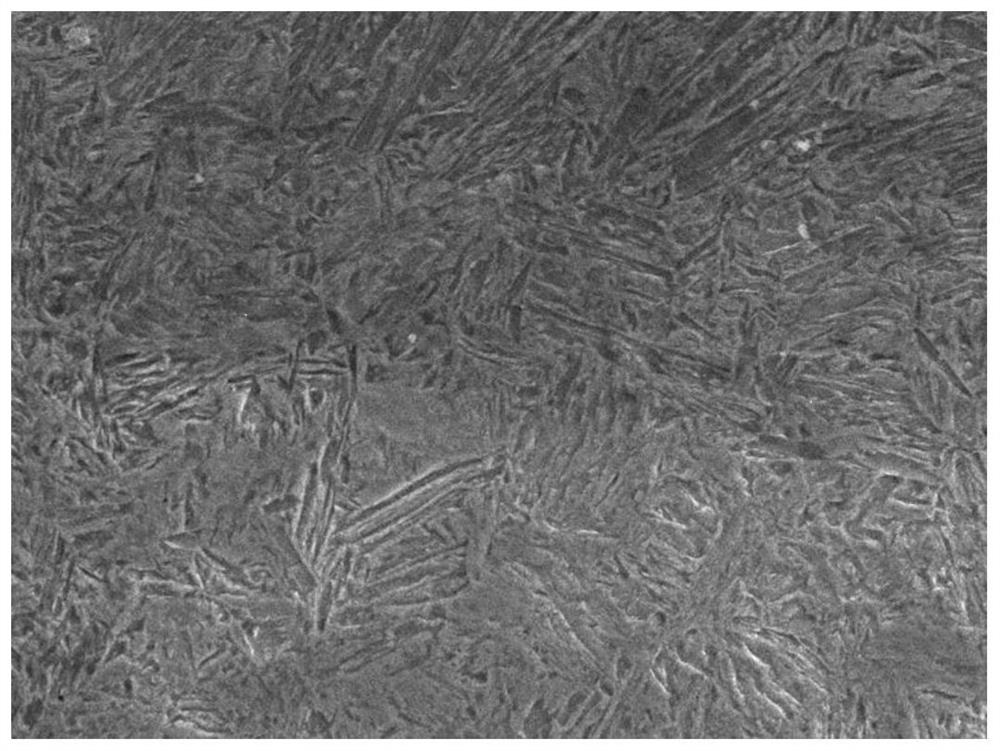

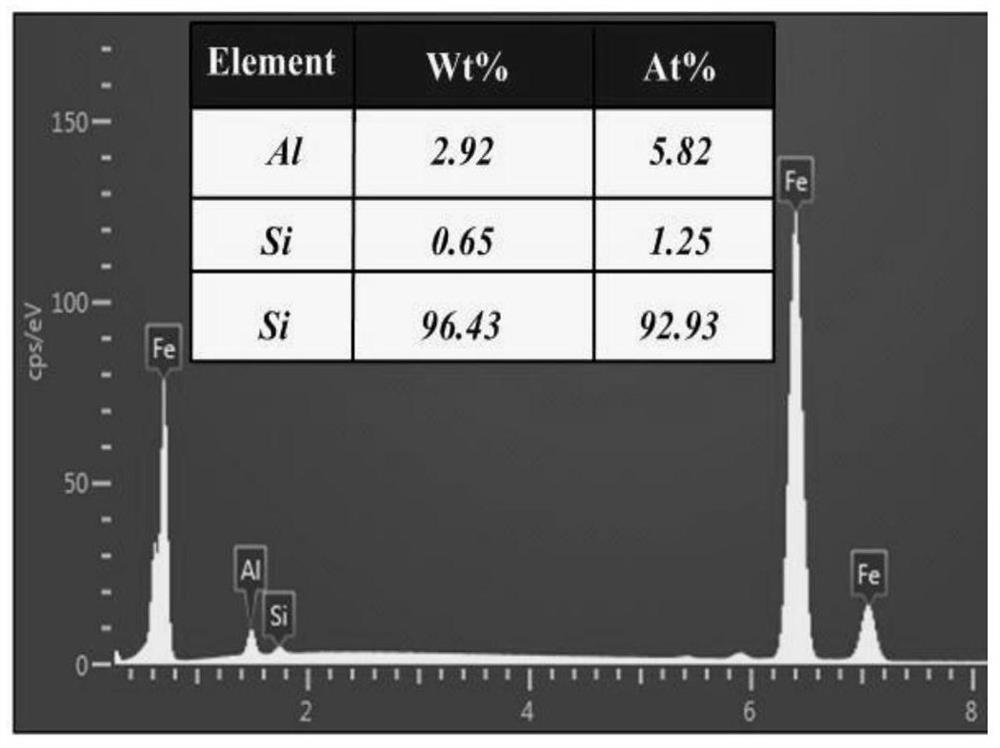

[0025] A kind of flux and process for laser welding of hot-formed steel coated with Al-Si coating on the surface of the present invention, by using molten salt and metal oxide as flux, coating removal and laser welding are implemented simultaneously, melting The physical and chemical reaction of the molten salt and metal oxide with the Al-Si coating on the surface of the hot-formed steel sheet in the metallurgical process improves the weldability of the hot-formed steel coated with the Al-Si coating and reduces the Al in the laser welding process. - After the Si coating is melted, the Al element dissolves or penetrates into the weld seam and Fe element to form a Fe-Al intermetallic compound, the microhardness of the weld seam area is significantly reduced, and the plasticity and toughness are improved, so as to improve the mechanical properties of the laser tailor welded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com