Filter screen cleaning device for petroleum filtering processing

A technology of cleaning device and filter screen, applied in the direction of filtration and separation, refining by filtration method, fixed filter element filter, etc., can solve the problems of insufficient thoroughness, slow cleaning speed, and difficulty in normal filtration, so as to prolong the service life and improve the stability. The effect of sex and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

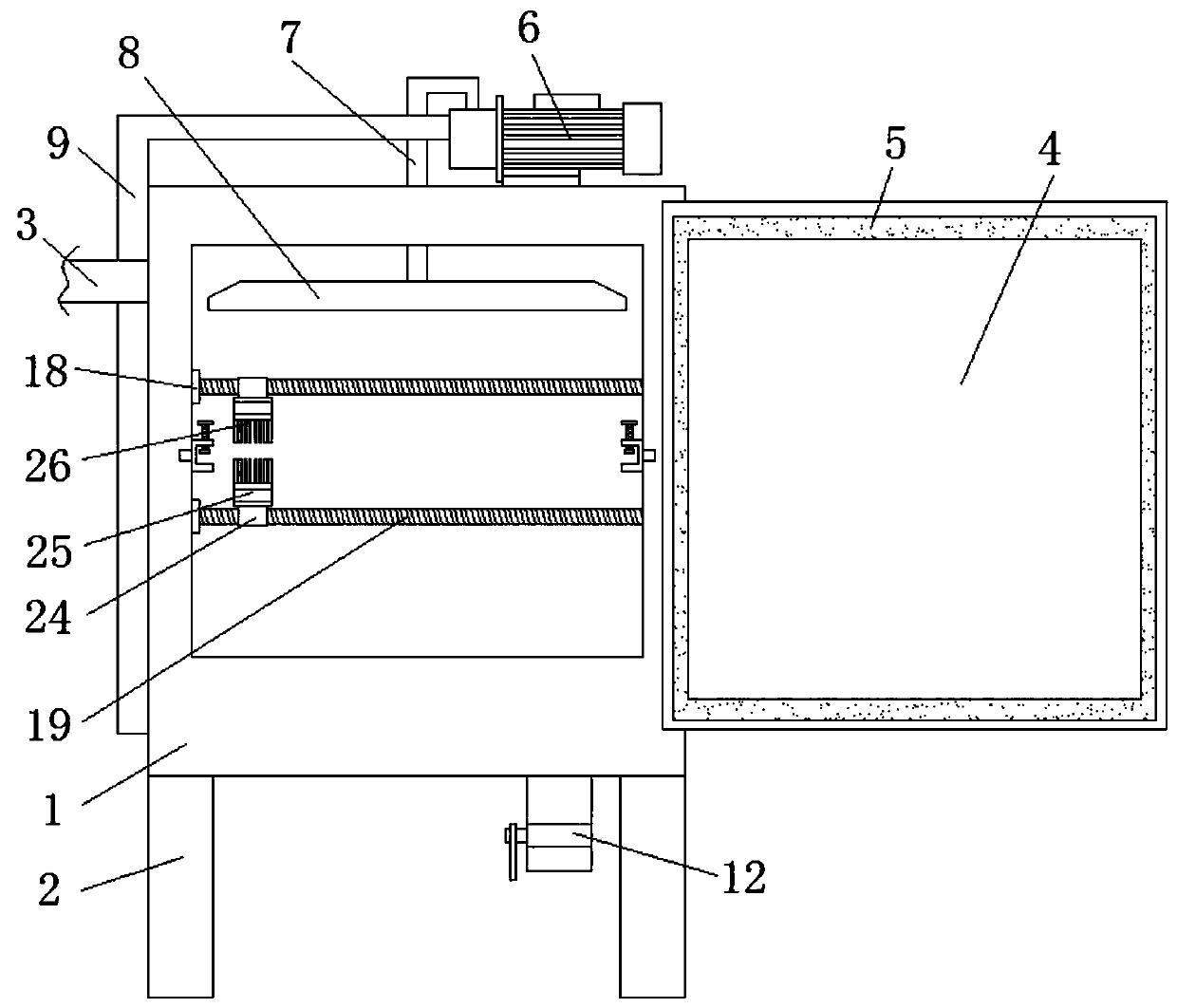

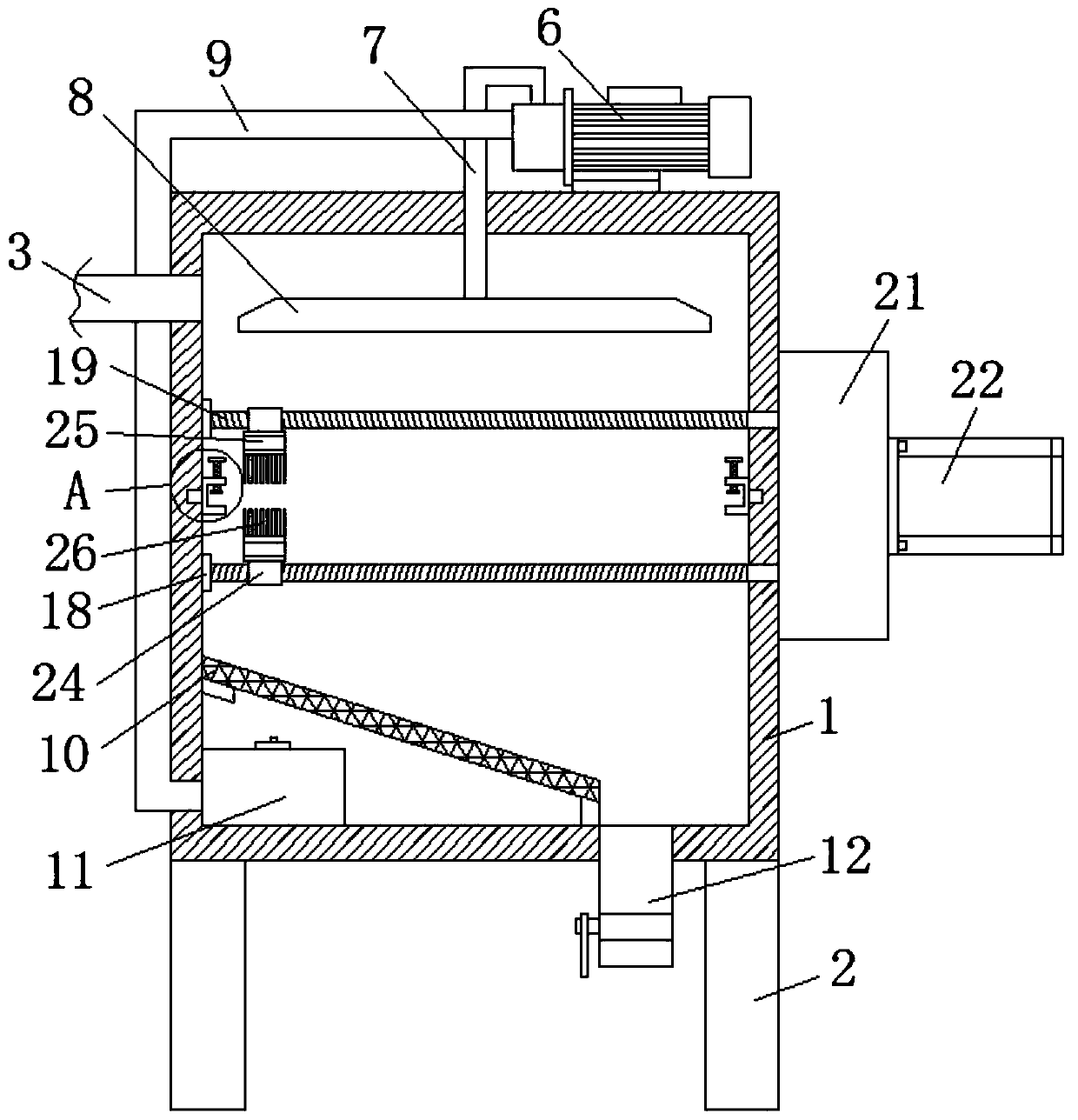

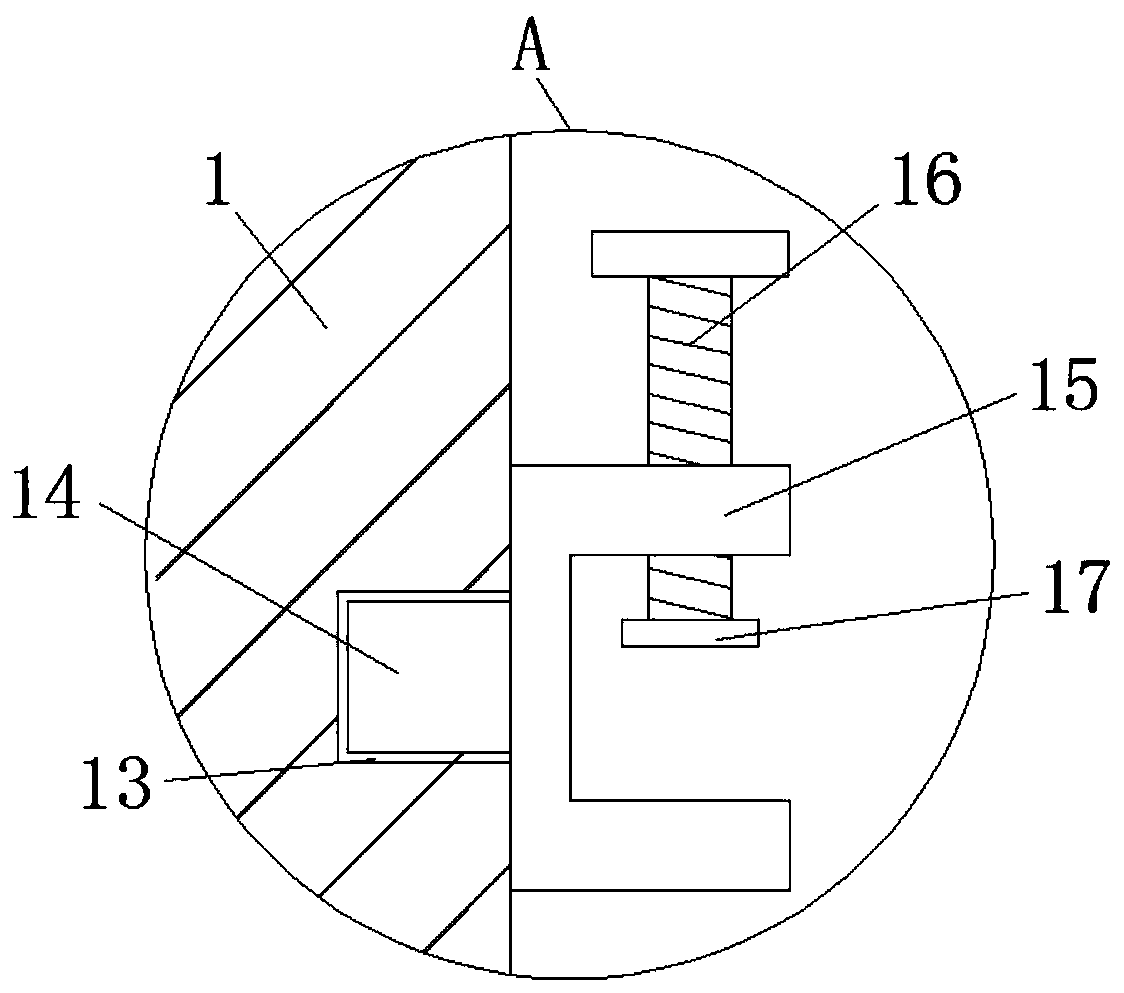

[0033] see Figure 1-7, the present embodiment provides a filter screen cleaning device for oil filtration processing, comprising a box body 1, the four corners of the lower surface of the box body 1 are fixedly connected with support legs 2, the box body 1 is hinged with a box door 4, the box body 1 A sealing gasket 5 is fixedly connected to the door 4, a water inlet pipe 3 is fixedly connected to one side of the box body 1, and the water inlet pipe 3 is connected with the inside of the box body 1, and a water pump 6 is fixedly connected to the upper surface of the box body 1. The outlet end is fixedly connected with an outlet pipe 7, and the outlet pipe 7 longitudinally runs through the box body 1 and is fixedly connected with a shower head 8, and the water inlet end of the water pump 6 is fixedly connected with a conduit 9, and the other end of the conduit 9 is connected to the bottom of the box body 1. One side of the end is fixedly connected, and the interior is connected...

Embodiment 2

[0036] see Figure 2-6 , a further improvement has been made on the basis of Embodiment 1: limit screws 29 are provided at the positions corresponding to the blocks 28 on one end of the two connecting plates 25, and the limit screws 29 penetrate through the connecting plate 25 transversely, and the limit screws are used to 29, play the role of limit, can effectively prevent the brush 26 and the connection plate 25 from detaching during use, affecting the cleaning of the filter screen, simple in structure, easy to operate, the inclination angle between the first filter screen 10 and the horizontal plane 30°, by setting the first filter screen 10 inclined at 30 degrees, it is convenient to separate the cleaning liquid and impurities, and at the same time, it is convenient for impurities to flow to the drain pipe 12 along the first filter screen 10 .

[0037] Wherein, the model of water pump 6 is JET-G17-37, and the model of motor 22 is .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com