Low-loss flexible circuit board

A flexible circuit board, low-loss technology, applied in the direction of circuit devices, printed circuit components, conductive pattern layout details, etc., can solve the problem that the radio frequency transmission performance is difficult to further improve, to reduce the equivalent dielectric constant and loss, reduce Effect of FPC thickness and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

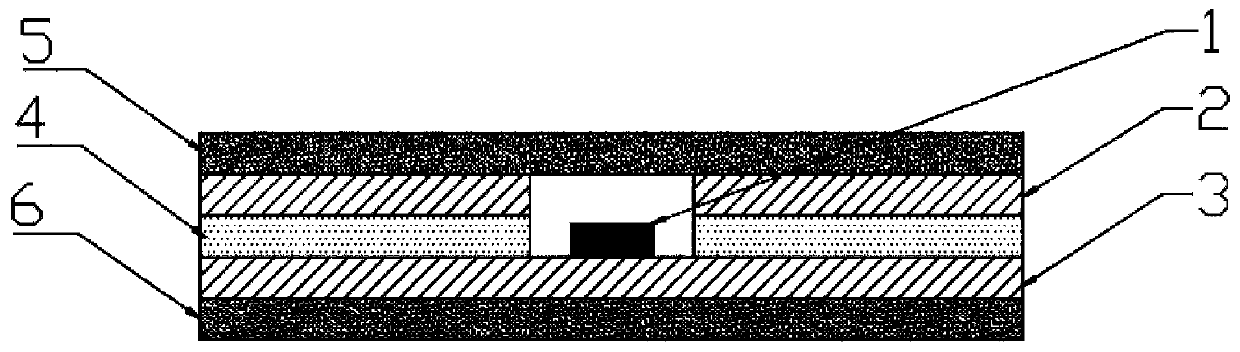

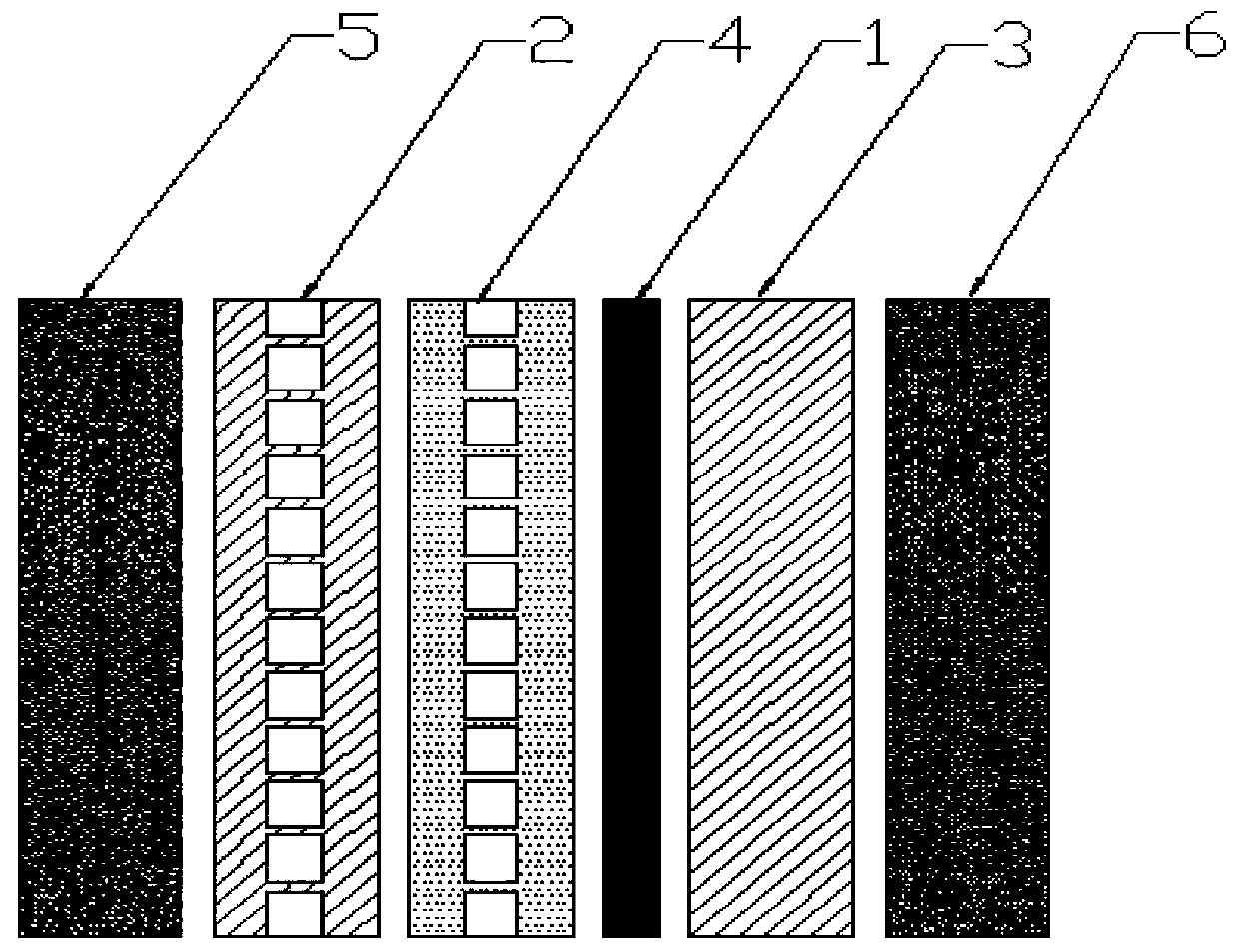

[0022] A low-loss flexible circuit board, comprising a signal line (1) and a first insulating layer (2) and a second insulating layer (3) respectively located on the upper side and the lower side of the signal line (1), the first insulating layer (2 ) and the second insulating layer (3) are connected through the first adhesive layer (4), the signal line (1) is in the same layer as the first adhesive layer (4), and the signal line (1) is pasted on the second insulating layer (3 ), the first insulating layer (2) and the first glue layer (4) are hollowed out in a grid pattern at the position of the signal line, and there is a first insulating layer (2) and the second insulating layer (3) outside A reference layer (5) and a second reference layer (6).

[0023] Specifically, the insulating layer is PI (polyimide) or MPI (heterogeneous PI) or LCP (liquid crystal polymer) material, and the reference layer is copper foil.

Embodiment 2

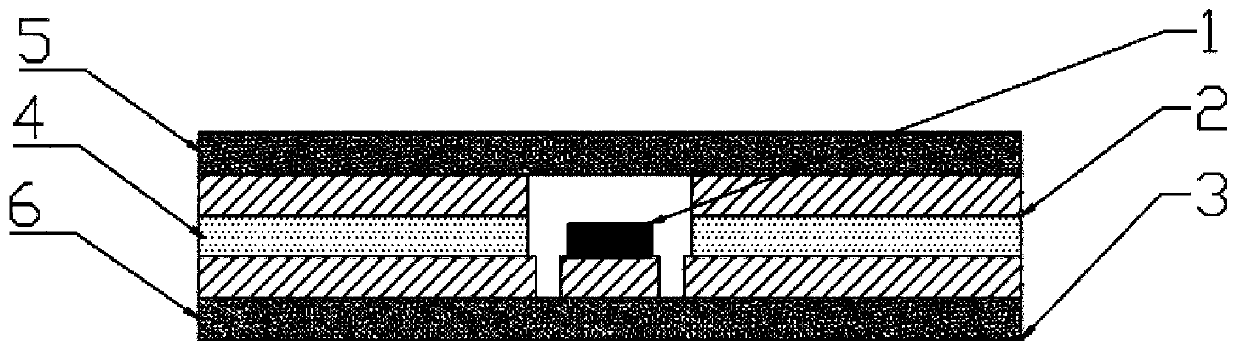

[0025] A low-loss flexible circuit board, comprising a signal line (1) and a first insulating layer (2) and a second insulating layer (3) respectively located on the upper side and the lower side of the signal line (1), the first insulating layer (2 ) and the second insulating layer (3) are connected through the first adhesive layer (4), the signal line (1) is in the same layer as the first adhesive layer (4), and the signal line (1) is pasted on the second insulating layer (3 ), the first insulating layer (2) and the first adhesive layer (4) are hollowed out in a grid pattern at the position of the signal line, and the part of the second insulating layer (3) that is not facing the signal line is hollowed out. There are also a first reference layer (5) and a second reference layer (6) outside the insulating layer (2) and the second insulating layer (3).

[0026] Specifically, the insulating layer is PI (polyimide) or MPI (heterogeneous PI) or LCP (liquid crystal polymer) mater...

Embodiment 3

[0028] A low-loss flexible circuit board, comprising a signal line (1) and a first insulating layer (2) and a second insulating layer (3) respectively located on the upper side and the lower side of the signal line (1), the first insulating layer (2 ) and the second insulating layer (3) are connected through the first adhesive layer (4), the signal line (1) is in the same layer as the first adhesive layer (4), and the signal line (1) is pasted on the second insulating layer (3 ), the first insulating layer (2) and the first adhesive layer (4) are hollowed out in a grid pattern at the position of the signal line, and there is a third insulating layer (7) on the lower side of the second insulating layer (3). The insulating layer (7) is connected to the second insulating layer (3) through the second adhesive layer (8), and there are also a first reference layer (5) and a second insulating layer (5) outside the first insulating layer (2) and the third insulating layer (7). Two ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com