High bandwidth organic substrate antenna structure and manufacturing method

An organic substrate and antenna structure technology, applied in the field of communication antennas, can solve the problems of restricting large-scale market application, difficult process, complex process, etc., and achieve the effect of reducing the equivalent dielectric constant, mature process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0050] The high bandwidth organic substrate antenna structure is fabricated through the following steps,

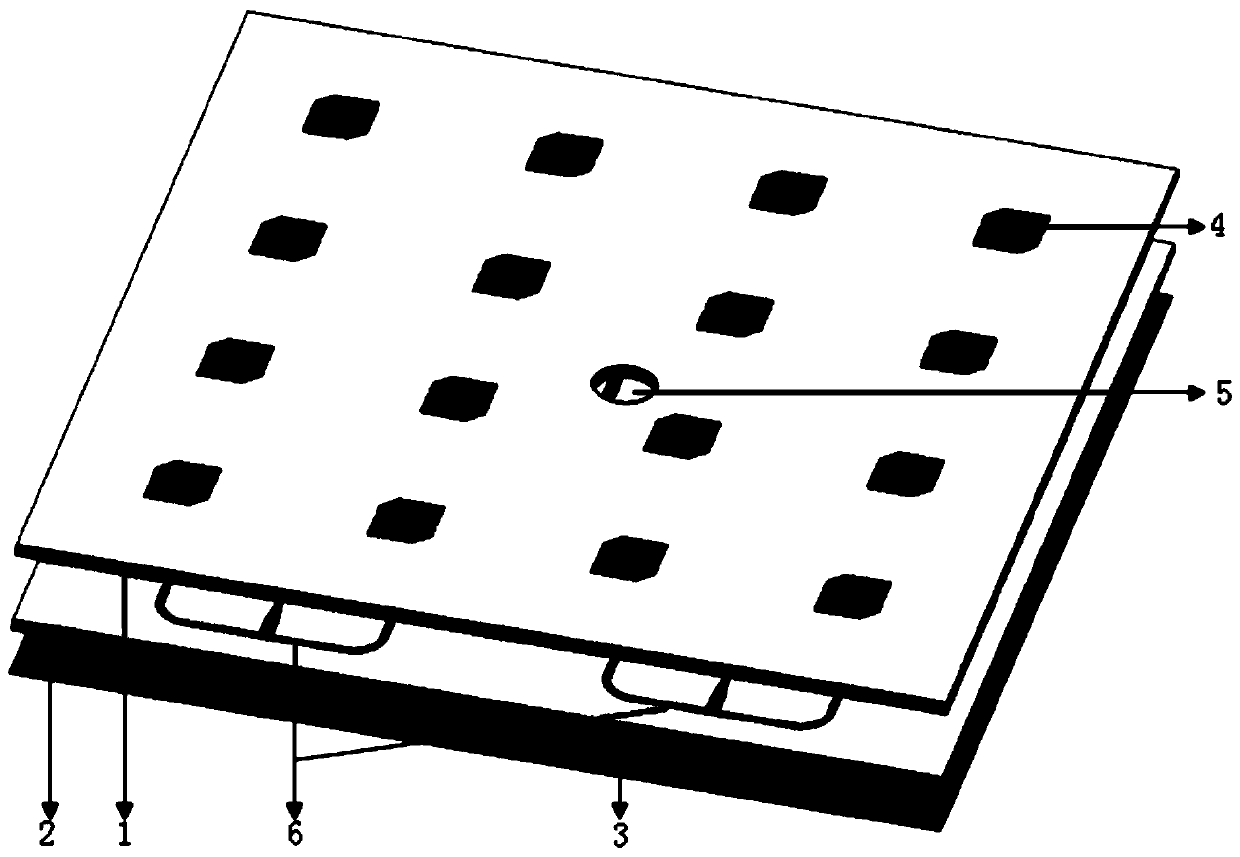

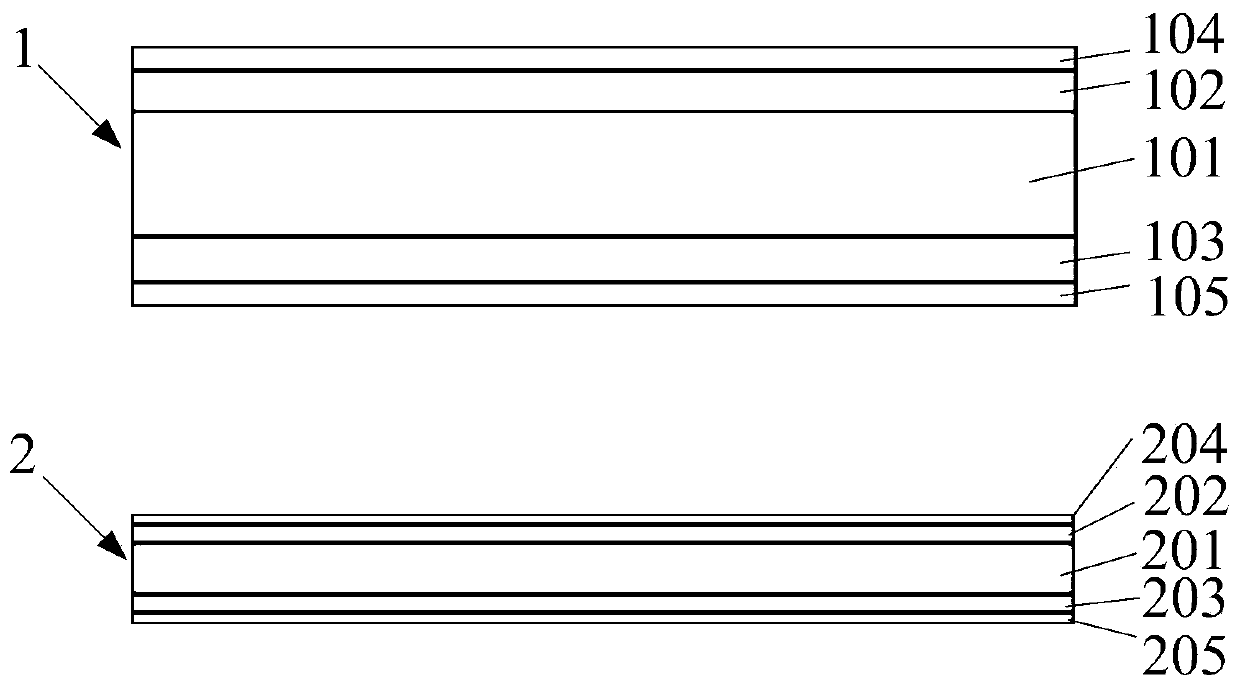

[0051] Step S1, such as image 3 As shown, an upper organic substrate 1 and a lower organic substrate 2 are provided;

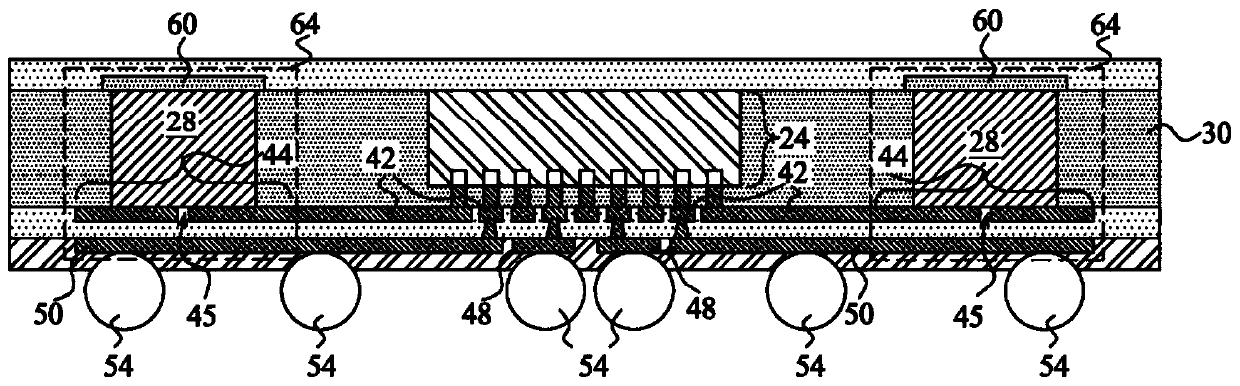

[0052] The upper organic substrate 1 includes a first inner core board 101, and a first copper layer 104 and a second copper layer laminated on the upper and lower surfaces of the first inner core board 101 through the first PP layer 102 and the second PP layer 103, respectively. 105;

[0053] The PP layer is the prepreg layer. Prepreg is a prepreg material, which is a thin sheet material impregnated with resin and cured to an intermediate level (B stage);

[0054] The lower organic substrate 4 includes a second inner core board 201, and a third copper layer 204 and a fourth copper layer laminated on the upper and lower surfaces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com