Spray glue raw material storage tank, storage equipment and storage system

A storage system and raw material technology, applied in the direction of tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of inconvenient use, loud motor noise, etc., to achieve the effect of ensuring uniformity, avoiding wear and tear, and facilitating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

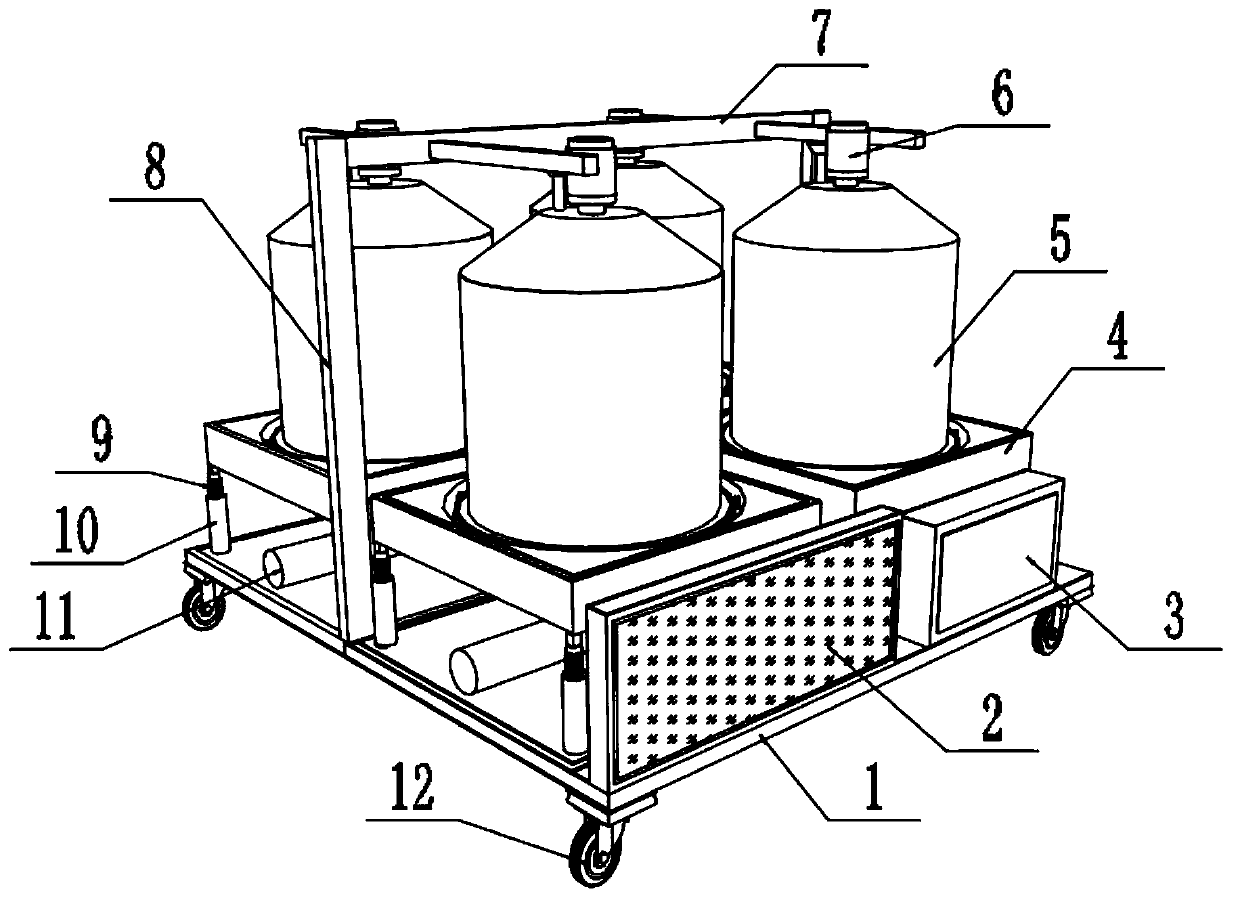

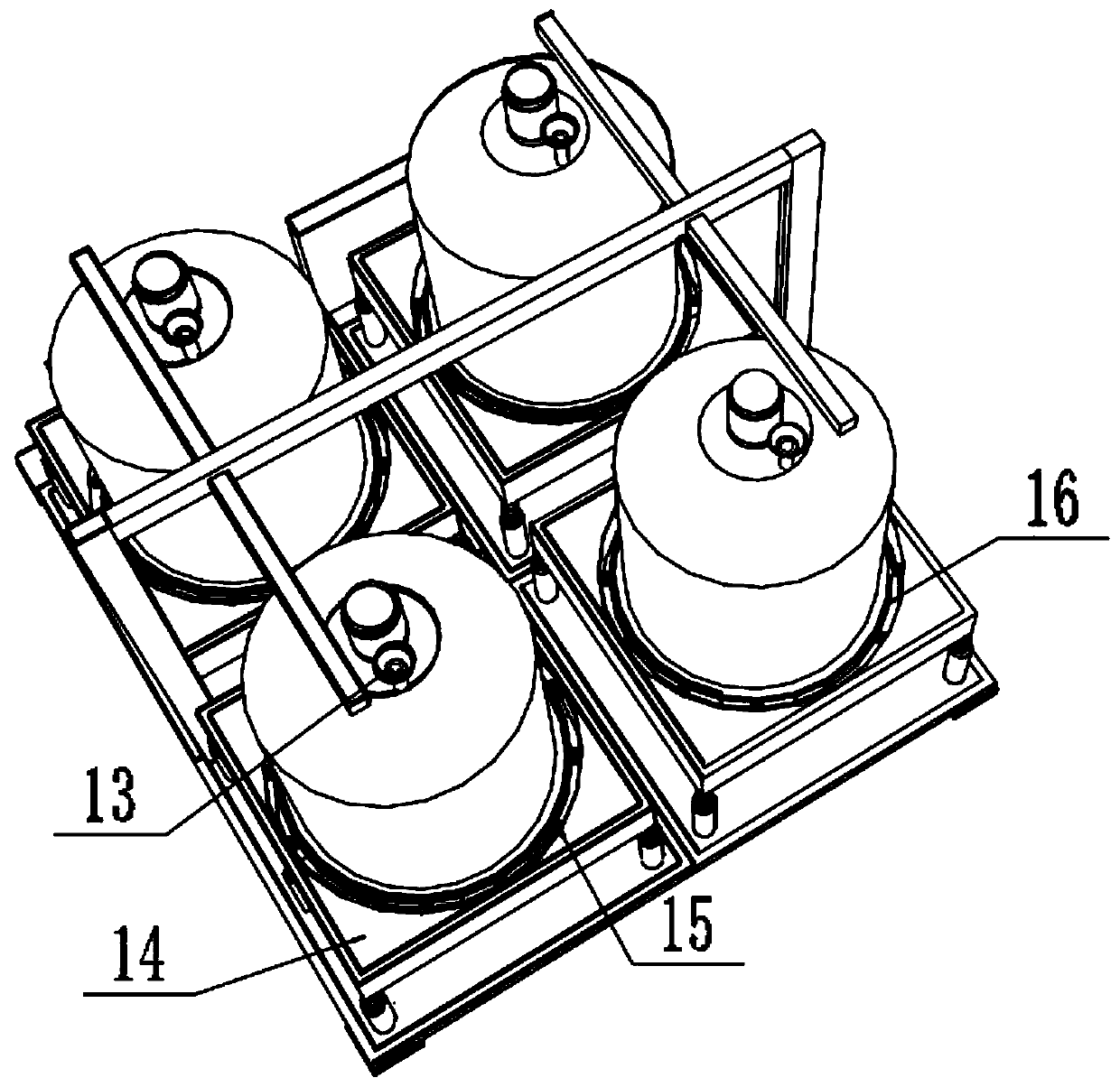

[0027] see Figure 1~4 , in an embodiment of the present invention, a glue spraying raw material storage tank, storage device and storage system, including a storage unit, a protection unit, a detection unit, a heating unit and a control unit.

[0028] The storage unit includes a tank body 5, and the heating unit includes a heating pipe 17, which is welded to the inner wall of the tank body 5, and the number of the heating pipe 17 is not limited. In this embodiment, preferably, the heating The number of tubes 17 is more than four, and the heating tubes 17 are in a circular structure, which can be heated efficiently. The top of the tank body 5 is fixed with a No. 1 motor 6 through a motor base, and the output shaft of No. 1 motor 6 is passed through a shaft coupling. The stirrer is connected with a stirrer 18, and the stirrer 18 is fixed on the inside of the tank body 5 through bearings; the shaking of the raw materials in the tank can be kept by the motor to mobilize the stirr...

Embodiment 2

[0035] see Figure 5 , a glue spray raw material storage tank, storage equipment and storage system. In order to improve the cleaning efficiency of the storage tank, this embodiment makes the following improvements on the basis of Embodiment 1: the side wall of the tank body 5 is welded with an outer water cylinder 23 , and the side wall of the outer water cylinder 23 is welded with a support platform 19, the top of the support platform 19 is fixed with a water pump 20 by screws, and the output end of the water pump 20 is connected with a shower nozzle fixed on the inner wall of the top of the tank body 5 through a spray pipe 21, and the water pump 20 The pumping end of the pump communicates with the outer water cylinder 23 through a conduit.

[0036] In order to increase the thermal insulation effect of the storage tank, the tank body 5 is provided with a thermal insulation layer 22, the heating pipe 17 is fixed in the thermal insulation layer 22, and the thermal insulation l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com