Vehicle support arm hot pressing assembly device

An assembly device and support arm technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency and troubles, and achieve the effects of saving assembly time, increasing work power, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

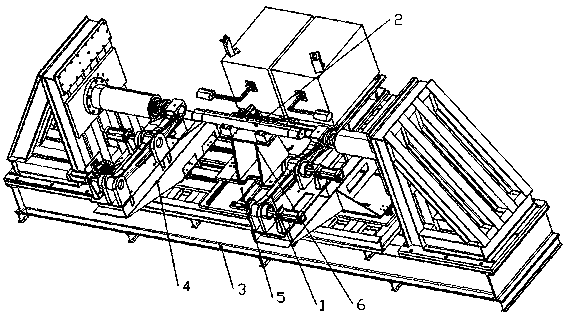

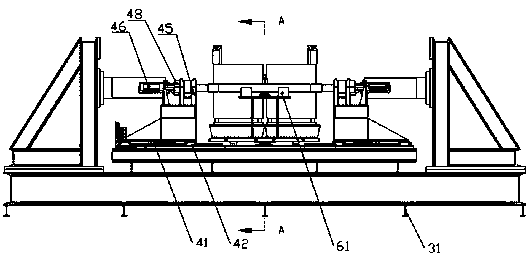

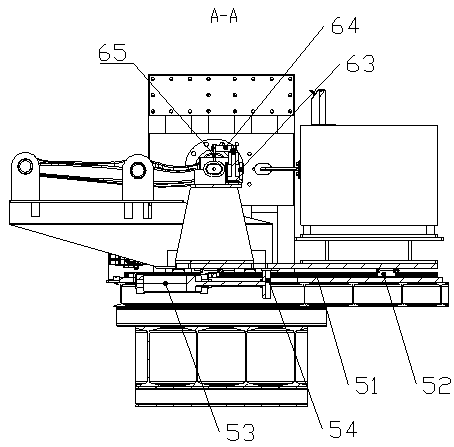

[0031] like Figure 1-Figure 6 Shown is a hot press assembly device for a car bracket, the car bracket includes a pair of guide arms 1 and a torsion bar 2 connecting the two guide arms 1, and a through hole is opened in the middle and both sides of the guide arm 1 , and one of the through holes located at the side end of the guide arm 1 is an insertion hole for the insertion of the torsion bar 2, and the remaining two holes of the guide arm 1 are connection holes connected with other components.

[0032] Shrink assembly unit includes

[0033] An assembly base 3, the assembly base 3 is a rectangular parallelepiped frame structure composed of several horizontal I-shaped steels and longitudinal I-shaped steels, the bottom end of the assembly base 3 is distributed side by side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com