Fine mineral separation method combining cavitation pretreatment and carrier flotation

A mineral separation and pretreatment technology, applied in flotation, solid separation, etc., can solve the problems of increasing the dosage of flotation agents, deteriorating the quality of concentrate, and high performance, so as to improve the flotation speed and selectivity, and improve the flotation efficiency. The effect of selecting selectivity and increasing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

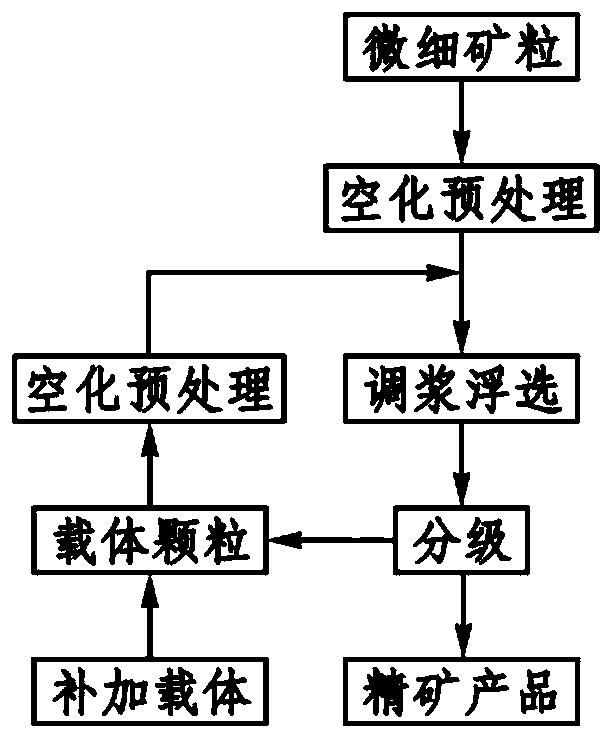

[0031] The fine mineral samples are two kinds of -0.074mm grain size coal slime from a mining area in Zhungeer Banner, Ordos City, Inner Mongolia Autonomous Region. 1 # Micro slime. The carrier particles are 0.5-0.25mm coal slime from a coal preparation plant in Etuokeqianqi, Ordos City, Inner Mongolia Autonomous Region. Table 1 is the industrial analysis results of 1# and 2#-0.074mm fine coal slime and carrier coal particles. The test adopts traditional direct flotation process, carrier flotation process and fine mineral separation process combined with cavitation pretreatment and carrier flotation to carry out flotation of -0.074mm particle size coal slime, and the tests are all carried out in the laboratory. figure 1 It is a schematic diagram of the fine mineral separation process combined with cavitation pretreatment and carrier flotation.

[0032] Table 1 Industrial analysis results of fine coal slime and carrier coal particles

[0033] sample M ad (%)

A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com