Preparation method and applications of flexible and high-selectivity non-enzymatic uric acid electrode carbon fiber membrane of self-supporting carbon fiber

A carbon fiber membrane and high-selectivity technology, applied in the field of electrochemistry, can solve problems such as no public reports, and achieve significant economic and social benefits, high flexibility, and fast measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

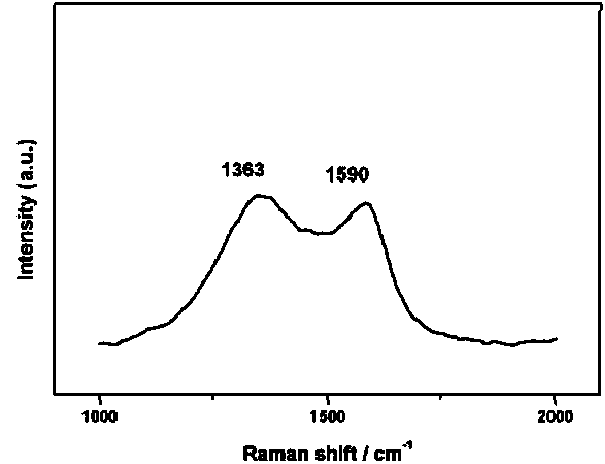

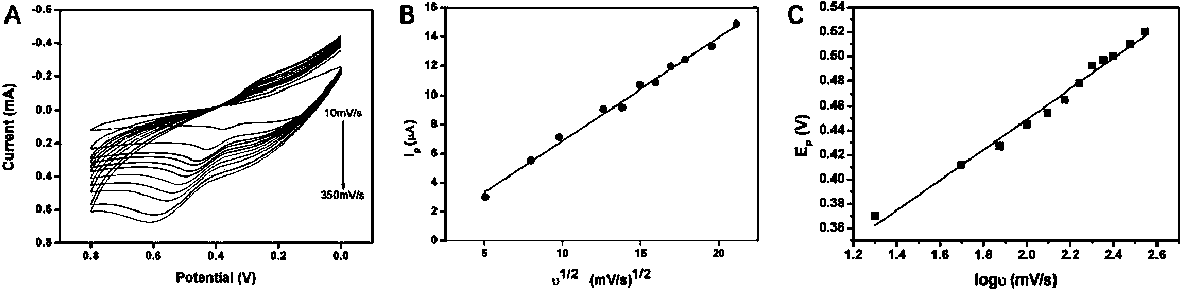

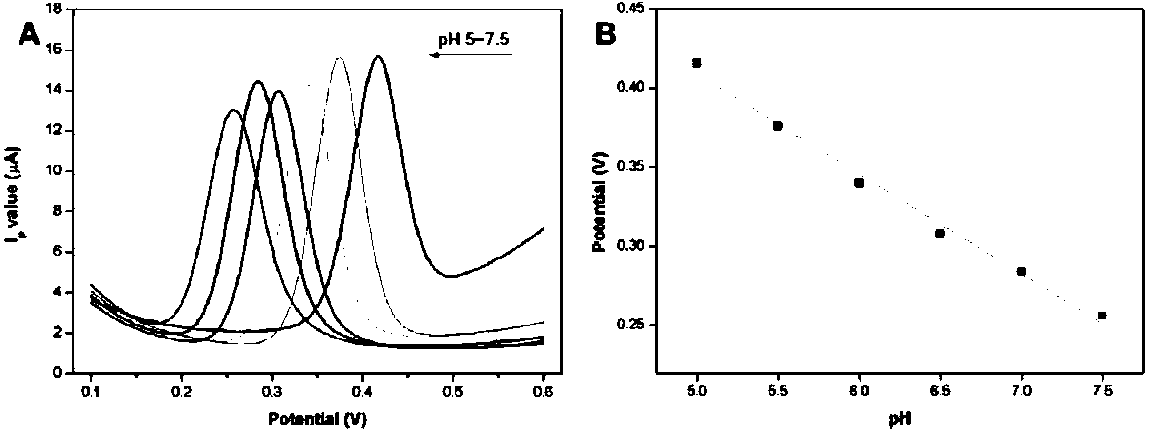

[0014] A kind of flexible, highly selective non-enzymatic uric acid electrode carbon fiber film preparation method of self-supporting carbon fiber of the present invention, in concrete implementation, polyacrylonitrile (Polyacrylonitrile, namely PAN) is dissolved in N,N-dimethylformamide (N,N-dimethylformamide, ie DMF), to make an electrospinning precursor containing polyacrylonitrile mass concentration of 12%, by applying a 10kv voltage between the needle and the aluminum foil collector to carry out electrospinning, from the needle to the receiver The distance between the spinners was 10cm, and the flow rate of the precursor was 0.5mL / h; after spinning, the prepared polymer nanofiber membrane was dried in a vacuum oven at 60°C for 12h to make the N,N-dimethylformaldehyde The amide was volatilized; and then the dried polymer nanofiber membrane was put into a quartz tube furnace for heat treatment. First, the temperature was raised to 250°C in the air at a rate of 0.5°C / min, and...

Embodiment 2

[0020] The invention discloses a flexible and highly selective non-enzymatic uric acid electrode carbon fiber membrane preparation method for self-supporting carbon fibers, which comprises dissolving polyacrylonitrile in N,N-dimethylformamide to make polyacrylonitrile containing polyacrylonitrile with a mass concentration of 11 % electrospinning precursor, electrospinning was carried out by applying a voltage of 9kv between the needle and the aluminum foil collector, the distance from the needle to the receiver was 9cm, and the flow rate of the precursor was 0.5mL / h; after spinning, the The prepared polymer nanofiber membrane was dried in a vacuum oven at 59°C for 13 hours to volatilize N,N-dimethylformamide; then the dried polymer nanofiber membrane was placed in a quartz tube furnace for heat treatment , first in the air at a heating rate of 0.5 °C / min to 245 °C, holding for 4.3 hours to shape the fiber, then in a nitrogen atmosphere at a heating rate of 2 °C / min to 770 °C, h...

Embodiment 3

[0026] The invention discloses a flexible and highly selective non-enzymatic uric acid electrode carbon fiber membrane preparation method for self-supporting carbon fibers, which comprises dissolving polyacrylonitrile in N,N-dimethylformamide to produce a polyacrylonitrile containing polyacrylonitrile with a mass concentration of 13 % electrospinning precursor, electrospinning was carried out by applying a voltage of 11kv between the needle and the aluminum foil collector, the distance from the needle to the receiver was 11cm, and the flow rate of the precursor was 0.5mL / h; after spinning, the The prepared polymer nanofiber membrane was dried in a vacuum oven at 61°C for 11.5 hours to volatilize N,N-dimethylformamide; then the dried polymer nanofiber membrane was placed in a quartz tube furnace for For heat treatment, first raise the temperature in the air to 255°C at a rate of 0.5°C / min, keep the temperature for 3.8 hours to shape the fiber, then raise the temperature to 830°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com