Method for manufacturing foam rubber

A foam rubber and a manufacturing method technology, applied in the foam rubber manufacturing field, can solve problems such as poor elasticity and durability of the puff, and achieve the effect of excellent elasticity and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Manufacture of polymer latex

[0113] In a pressure-resistant reaction vessel, add 200 parts of water, 1.5 parts of potassium oleate, 38 parts of acrylonitrile, 0.5 parts of tert-dodecyl mercaptan, 0.03 parts of sodium formaldehyde sulfoxylate, and 0.003 parts of sulfuric acid Ferrous iron, 0.008 parts of sodium edetate, and 45 parts of 1,3-butadiene and 17 parts of isoprene were added after fully degassing.

[0114]Next, 0.05 parts of cumene hydroperoxide was added as a polymerization initiator, and emulsion polymerization was initiated at a reaction temperature of 5°C. When the polymerization conversion rate reached 95%, a polymerization terminator solution containing 0.25 parts of diethylhydroxylamine and 5 parts of water was added to terminate the polymerization reaction to obtain an emulsion.

[0115] Then, after removing unreacted monomers from the obtained emulsion, 0.01 part of modified hydrocarbon oil (trade name "DF714S", manufactured by Seiko PMC Co., Ltd....

Embodiment 2

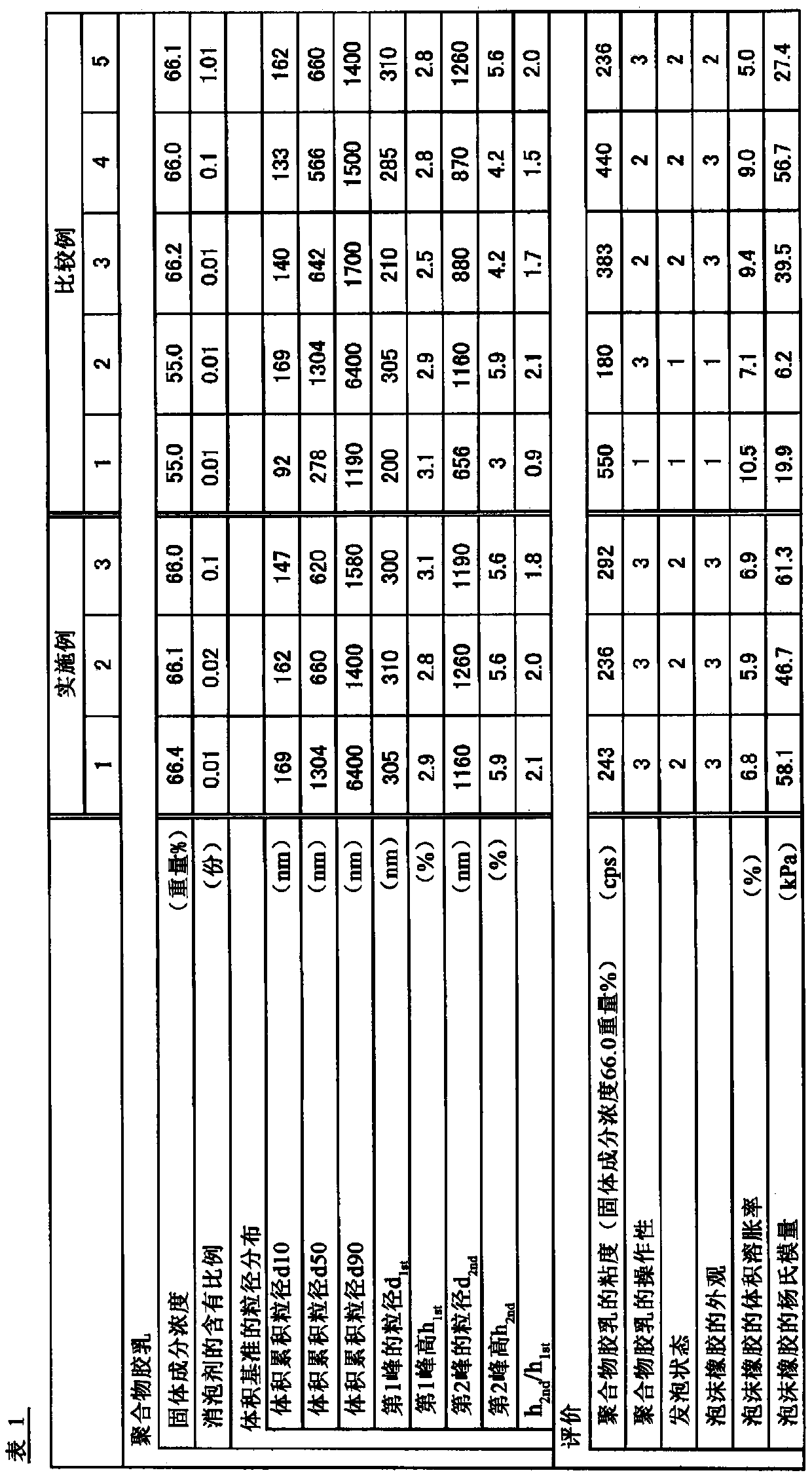

[0122] The usage amount of the antifoaming agent was changed from 0.01 part to 0.02 part, and the conditions of the particle size increasing treatment were changed to a rotation speed of 1200 rpm and a stirring time of 4.8 hours, except that it was carried out in the same manner as in Example 1 to produce a polymer latex The polymer latex and the foam rubber were evaluated in the same manner as the foam rubber. In addition, in Example 2, the solid content concentration of the polymer latex after the concentration treatment was 66.1% by weight. The results are shown in Table 1.

Embodiment 3

[0124] The usage amount of the antifoaming agent was changed from 0.01 part to 0.1 part, and the conditions of the particle size increasing treatment were changed to 900 rpm and stirring time of 4.5 hours, except that, the same procedure as in Example 1 was carried out to produce the polymer latex The polymer latex and the foam rubber were evaluated in the same manner as the foam rubber. In addition, in Example 3, the solid content concentration of the polymer latex after the concentration treatment was 66.0% by weight. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com