Mineral oil defoaming agent and preparation method thereof

A technology of mineral oil and defoamer, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., to achieve improved compatibility and fluidity, and better compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

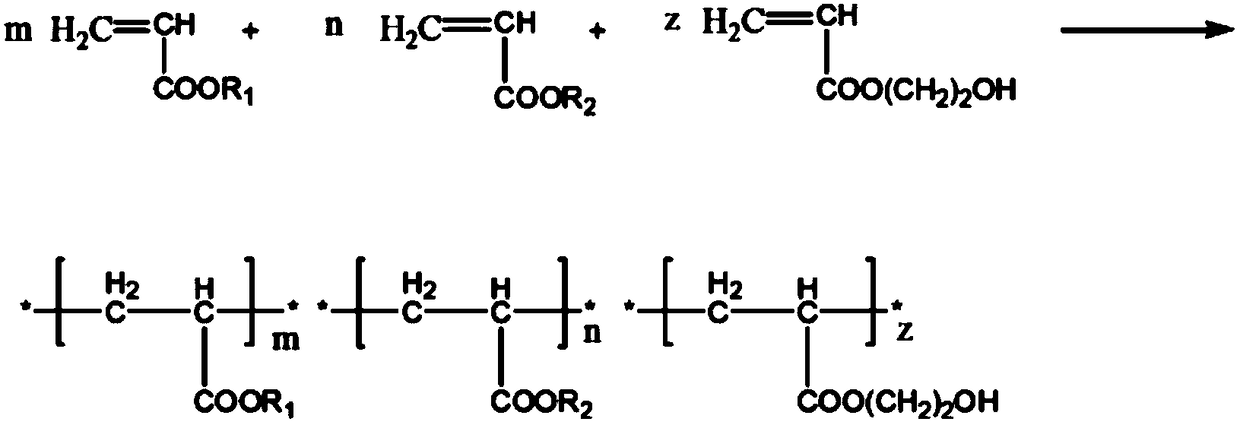

Method used

Image

Examples

Embodiment 1

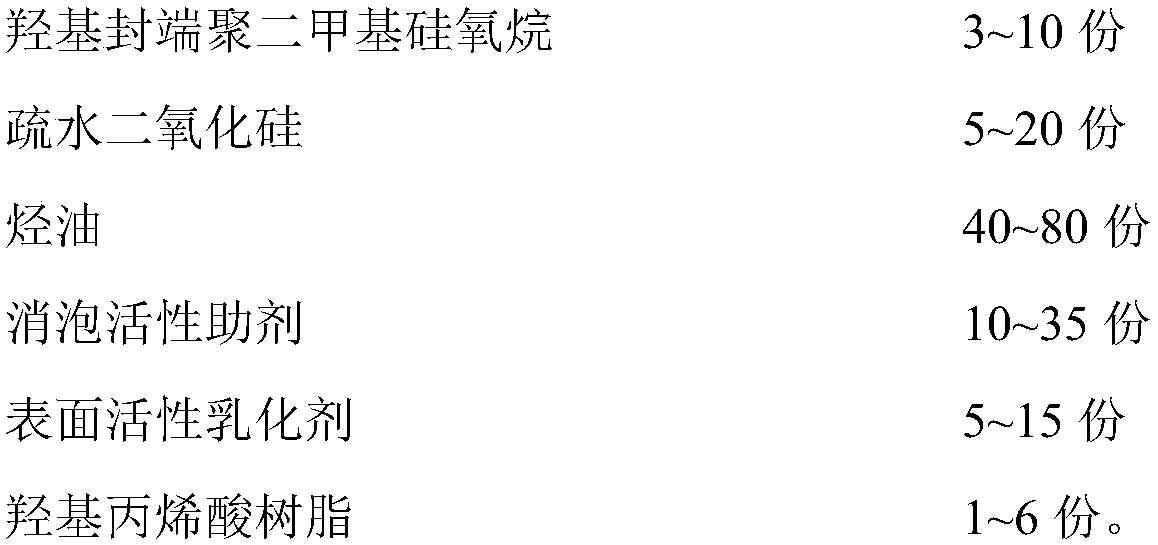

[0072] A kind of mineral oil defoamer of embodiment 1, comprises the following components by weight,

[0073]

[0074] A preparation method of the aforementioned mineral oil defoamer, comprising the following steps:

[0075] Take 3 parts of hydroxyl-terminated polydimethylsiloxane, add it to the cleaned reactor, slowly stir in batches (stirring speed is 40rpm), add hydrophobic fumed silica, stir evenly, increase the stirring speed to 80rpm, and Raise the temperature to 130±2°C at a speed of 5°C / min. After 2 hours of heat preservation, vacuumize (vacuum degree is -0.05mpa) and maintain this temperature for 0.5 hours. / min, the active silicon premix A liquid is obtained.

[0076] In another cleaned reactor, add mineral white oil, ethylene bisstearamide, and modified polyether fat to stir and raise the temperature to 120±2°C at a speed of 5°C / min, keep it warm for 2 hours, and then maintain this temperature Vacuumize for 0.5 hours (vacuum degree is -0.05mpa), add surface act...

Embodiment 2

[0078] A kind of mineral oil defoamer of embodiment 2, comprises the following components by weight,

[0079]

[0080] A preparation method of the aforementioned mineral oil defoamer, comprising the following steps:

[0081] Take 1.5 parts of hydroxyl-terminated polydimethylsiloxane, add it to the cleaned reactor, slowly stir in batches (stirring speed is 50rpm), add hydrophobic fumed silica, stir evenly, increase the stirring speed to 100rpm, and Raise the temperature to 140±2°C at a speed of 5°C / min. After 3 hours of heat preservation, vacuumize (vacuum degree is -0.05mpa) and maintain this temperature for 0.6 hours. / min, the active silicon premix A liquid is obtained.

[0082] In another cleaned reactor, add mineral white oil, fatty acid with 18 carbon atoms, ethylene bisstearamide, and modified polyether fat to stir and heat up to 130±2°C at a speed of 5°C / min. Insulate for 3 hours, then maintain this temperature and vacuum for 0.6 hours (vacuum degree is -0.05mpa, a...

Embodiment 3

[0084] A kind of mineral oil defoamer of embodiment 2, comprises the following components by weight,

[0085]

[0086]

[0087] A preparation method of the aforementioned mineral oil defoamer, comprising the following steps:

[0088] Take 5 parts of hydroxyl-terminated polydimethylsiloxane, add it to the cleaned reactor, slowly stir in batches (stirring speed is 70rpm), add hydrophobic fumed silica, stir evenly, increase the stirring speed to 120rpm, and Raise the temperature to 150±2°C at a speed of 5°C / min. After 4 hours of heat preservation, vacuumize (vacuum degree is -0.05mpa) and maintain this temperature for 1 hour. After the heat preservation is completed, disperse at a high speed for 0.5 hours, and the dispersion speed is 2000r / min, the active silicon premix A liquid is obtained.

[0089] In another cleaned reactor, add mineral white oil, double aluminum stearate, and modified polyether fat to stir and raise the temperature to 150±2°C at a speed of 5°C / min, ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com