On-line prediction method for causticity ratio in Bayer process alumina production high-pressure pipeline dissolution process

A technology of causticity ratio and high-pressure pipeline, which is applied in the field of soft measurement, can solve problems such as equipment scarring, cumbersome process, and detection lag, and achieve the effect of increasing dissolution output and reducing system fluctuations

Active Publication Date: 2020-03-06

NORTHEASTERN UNIV

View PDF7 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the dissolution process of the high-pressure pipeline is long and the detection is too late. The components of raw materials and ingredients, the operating status of production equipment, production process parameters and product quality cannot be sensed in real time.

In addition, in the high-pressure pipeline dissolution process, there are strong nonlinear relationships between production process parameters and complex process mechanisms (coexistence of three phases of solid, liquid, and gas, and simultaneous physical and chemical reactions, biochemical reactions, phase change reactions, and complex energy conversion processes), raw materials, etc. Frequent fluctuations in composition, scarring of equipment and other problems lead to large changes in working conditions, which seriously affect the detection and control effects

At present, in most enterprises that use the Bayer method to produce alumina, the detection task of caustic ratio is still completed by manual testing. The process is very cumbersome, and the detection results are seriously lagging and fluctuating greatly, which cannot effectively guide production.

[0004] At present, it has been proposed to combine the mechanism model based on material balance and neural network to predict the caustic ratio online, but these methods need to collect data during the dissolution process, such as the pressure and temperature of each dissolution device, leading to the results of the prediction model Lag, still can't really guide production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0041] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

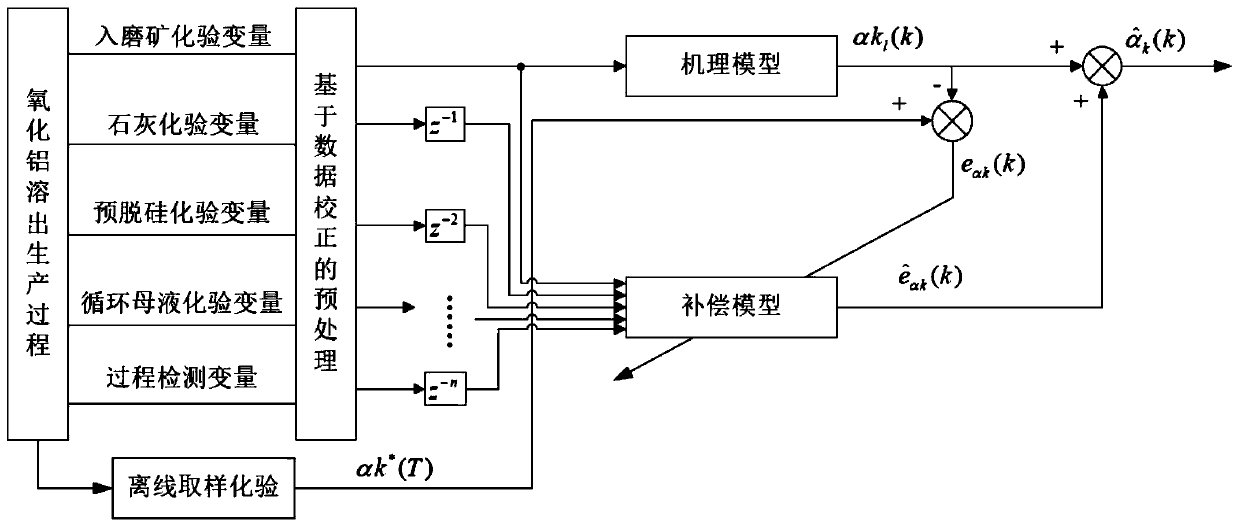

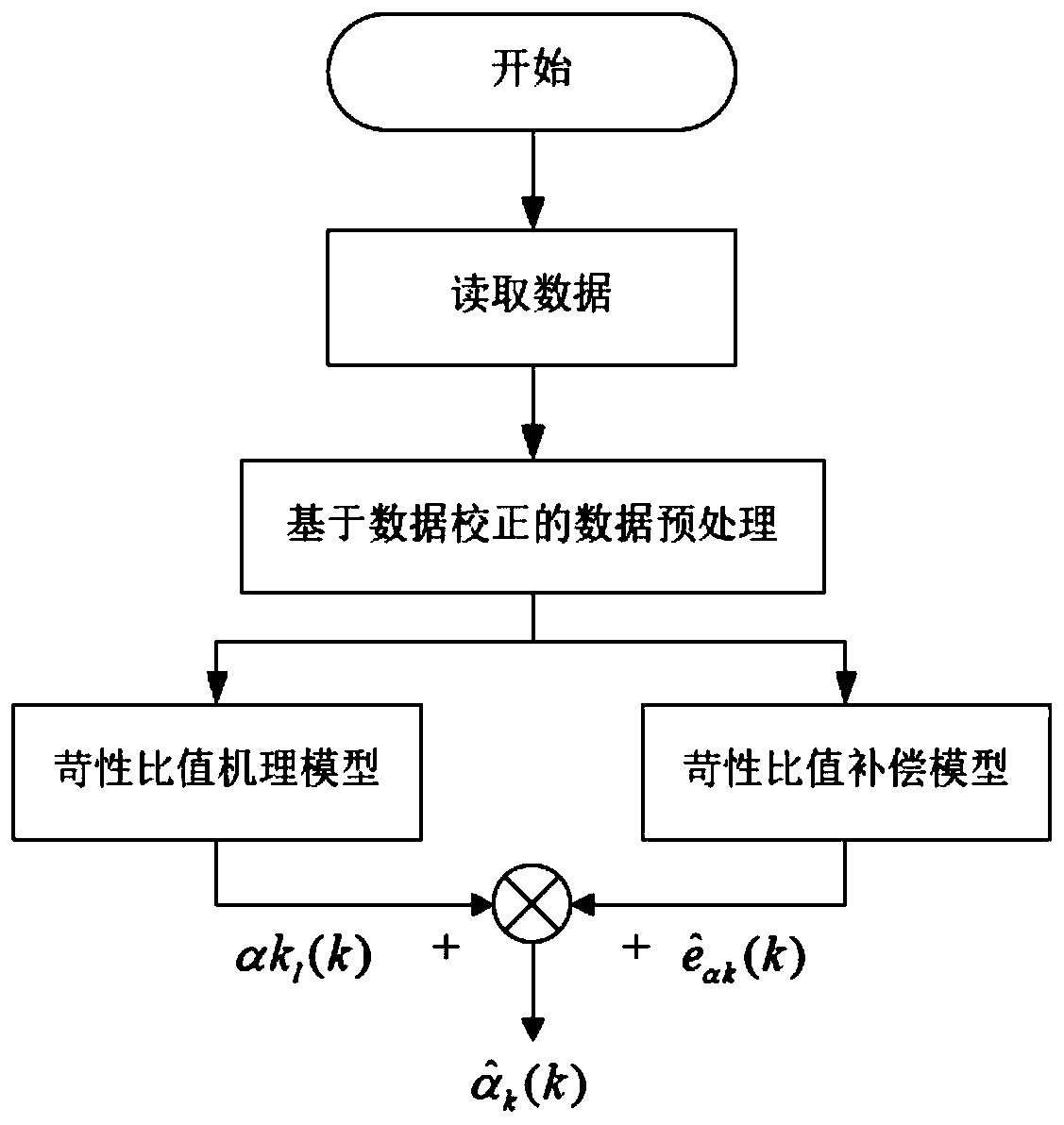

The invention relates to an on-line prediction method for a causticity ratio in a Bayer process alumina production high-pressure pipeline dissolution process. The method comprises four parts, namely data acquisition and transmission, preprocessing based on data correction, establishment of a mechanism model based on preprocessed data and a material balance principle, and establishment of a compensation model based on a recurrent neural network in combination with a mechanism model prediction value, an offline sampling test value and preprocessed data. According to the invention, the output result of the compensation model is adopted to compensate the predicted value of the mechanism model to obtain the final causticity ratio prediction result. Meanwhile, a model correction data set is formed by data of which the relative error between a prediction result and an actual test value after dissolution is lower than 0.1%, parameters of the recurrent neural network are retrained, and the adaptive capacity of the model is improved. The accuracy of the causticity ratio predicted by the online prediction method in the Bayer process alumina production high-pressure pipeline dissolution process is high, and a production enterprise can guide the setting of the feeding ratio and the secondary alkalifying flow according to the prediction result.

Description

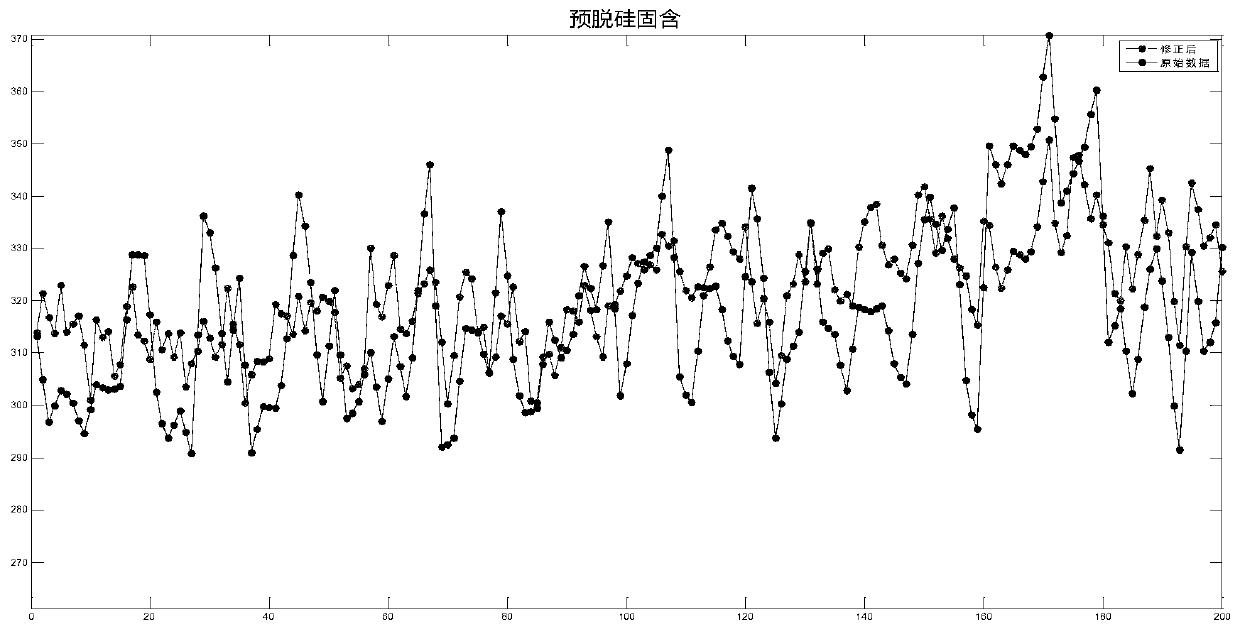

technical field [0001] The invention relates to the field of soft measurement technology and the field of key index prediction in the process industry, in particular to an online prediction method for the causticity ratio of the eluate in the high-pressure pipeline elution process of Bayer process alumina production. Background technique [0002] High-pressure pipeline dissolution is one of the main process links in the production of alumina by the Bayer process. During this process, Al in bauxite 2 o 3 Dissolved into the sodium aluminate solution. The control of the caustic ratio in the dissolution process of the high-pressure pipeline has a very important influence on the quality of the finished alumina product. The caustic ratio of the eluate (α k ) is the most critical technical index in the dissolution process of alumina high-pressure pipeline. Its size can not only reflect the alkali consumption within a period of time, but also affect the decomposition rate of subs...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06Q10/04G06N3/04C01F7/06

CPCG06Q10/04C01F7/0666G06N3/044G06N3/045

Inventor 柴天佑高愫婷贾瑶

Owner NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com