Protective device for fiber grating strain sensor of ocean platform splash zone

A strain sensor and fiber grating technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of failure to troubleshoot and on-site maintenance, the reliability of monitoring data cannot be guaranteed, and the survival time of sensors is lower than expected. Convenient to open for maintenance, avoid residual deviation, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

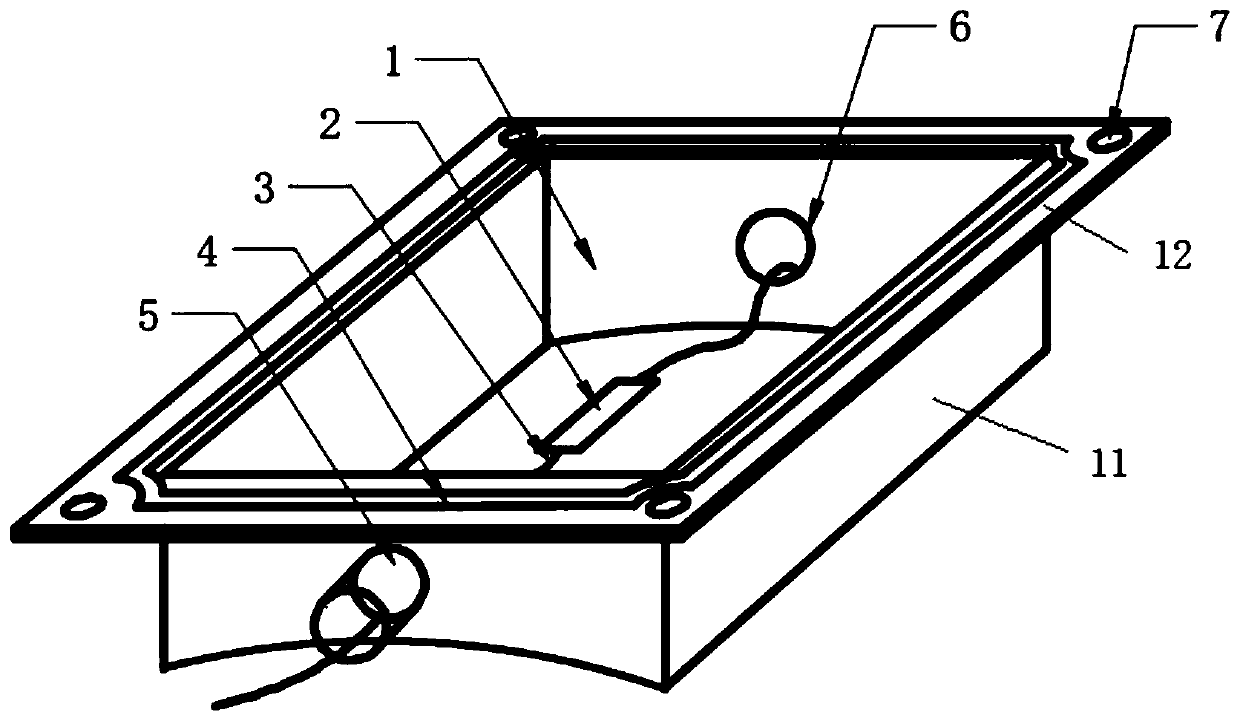

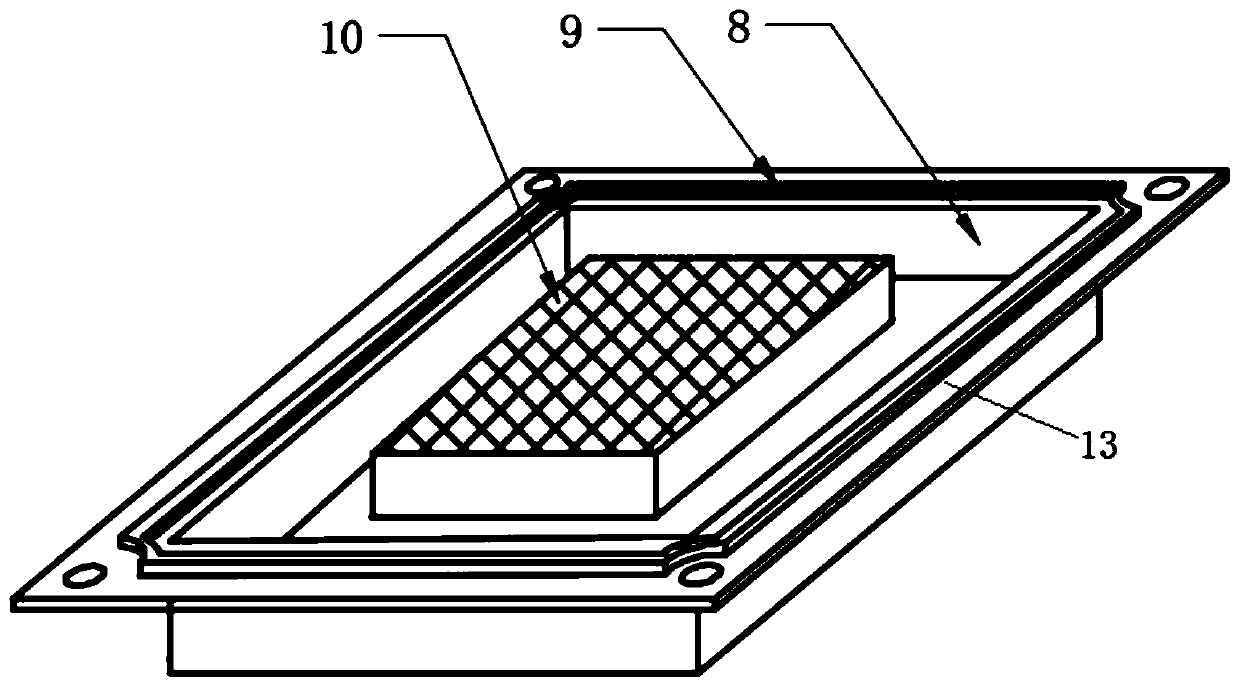

[0022] The present invention will be described below in conjunction with the accompanying drawings and embodiments. see figure 1 and figure 2 . The present invention is composed of a protective cover base 1 and a protective cover sealing cover 8, and is characterized in that: the protective cover base 1 is a rectangular structure without a bottom plate, so that the fiber grating strain sensor 2 is directly welded to the surface of the measured object, and the measurement accuracy is improved; The bottom of the upper and lower side plates of the cover base 1 is an arc structure, and the diameter of the arc is equal to the outer diameter of the platform leg at the installation position of the sensor in the splash zone, so that the base of the protective cover and the outer surface of the platform leg are seamlessly connected to achieve a full welding seal; protection The upper and lower side plates of the cover base 1 are respectively welded with an incoming line locking join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com