Heat preservation tee pipeline

A pipeline and three-way technology, applied in the field of thermal insulation three-way pipeline, can solve the problems of affecting the thermal insulation effect, time-consuming and laborious, heat dissipation, etc., and achieve the effects of good mechanical performance, damage prevention, and thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

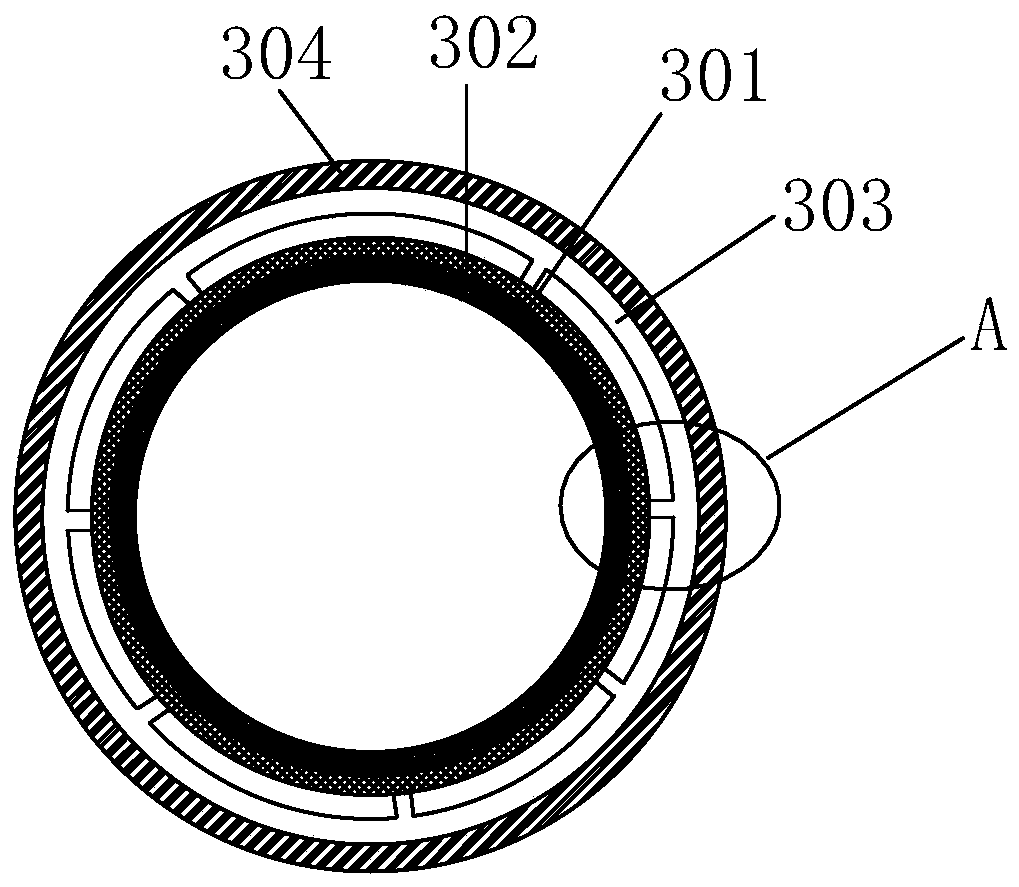

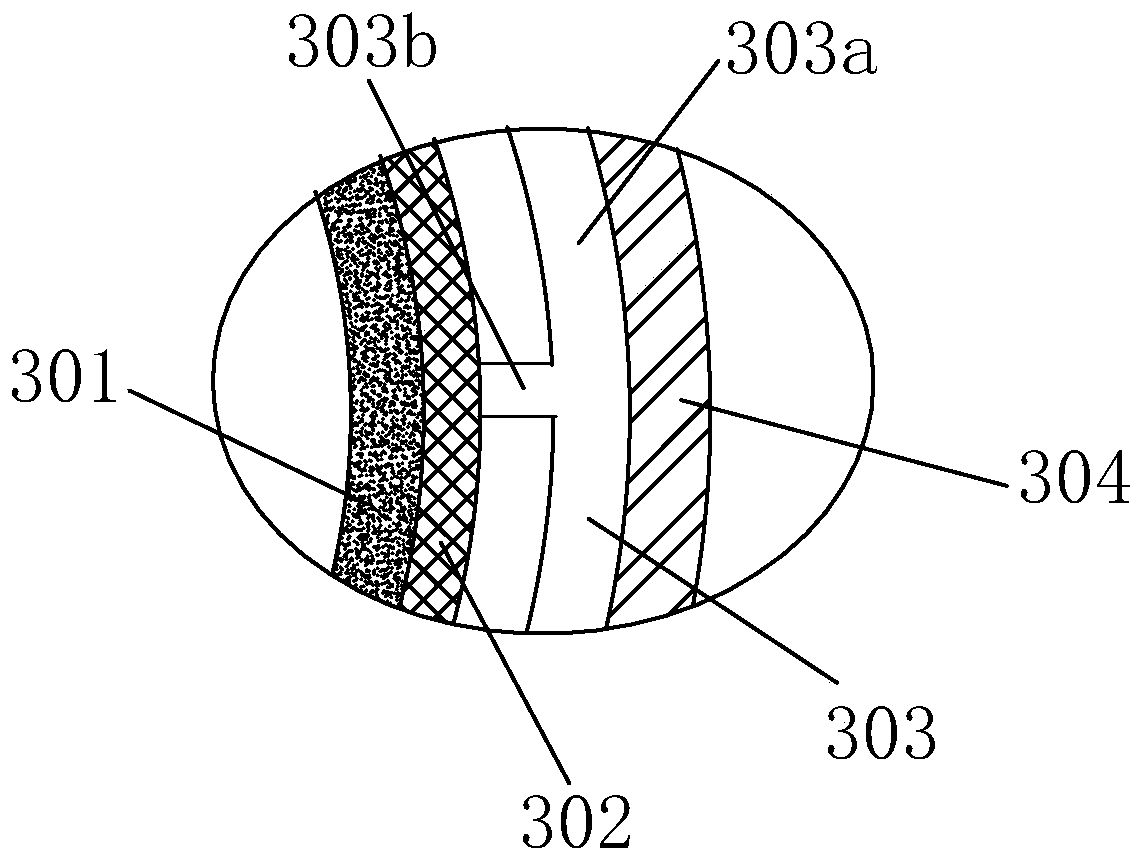

[0026] Such as figure 1 It is a schematic structural view of a three-way pipeline of the present invention, comprising a main pipeline 1 and a branch pipeline 2 integrally connected to the side wall of the main pipeline, the main pipeline is perpendicular to the branch pipeline, and the main pipeline and the branch pipeline communicate with each other. Between the side wall of the pipeline and the side wall of the branch pipeline, a fixing block 102 is provided to reinforce the connection between the main pipeline and the branch pipeline, and a main connecting part 101 is respectively provided at both ends of the main pipeline, and the free ends of the branch pipeline A sub-connection part 201 is provided at the end, and the main connection part and the sub-connection part are both cylindrical and the inner wall is provided with threads, such as figure 2 , image 3 are the cross-sectional schematic diagrams of branch pipes or branch pipes and figure 2 The schematic diagram...

Embodiment 2

[0034] Such as figure 1 It is a schematic structural view of a three-way pipeline of the present invention, comprising a main pipeline 1 and a branch pipeline 2 integrally connected to the side wall of the main pipeline, the main pipeline is perpendicular to the branch pipeline, and the main pipeline and the branch pipeline communicate with each other. Between the side wall of the pipeline and the side wall of the branch pipeline, a fixing block 102 is provided to reinforce the connection between the main pipeline and the branch pipeline, and a main connecting part 101 is respectively provided at both ends of the main pipeline, and the free ends of the branch pipeline A sub-connection part 201 is provided at the end, and the main connection part and the sub-connection part are both cylindrical and the inner wall is provided with threads, such as figure 2 , image 3 are the cross-sectional schematic diagrams of branch pipes or branch pipes and figure 2 The schematic diagram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal stabilization time | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com