A compound low-phosphorus corrosion inhibitor suitable for oilfield systems and its preparation method

A corrosion inhibitor and oilfield technology, applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of non-environmental protection, not easy to degrade, etc., achieve high corrosion inhibition performance, metal protection, corrosion inhibition Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

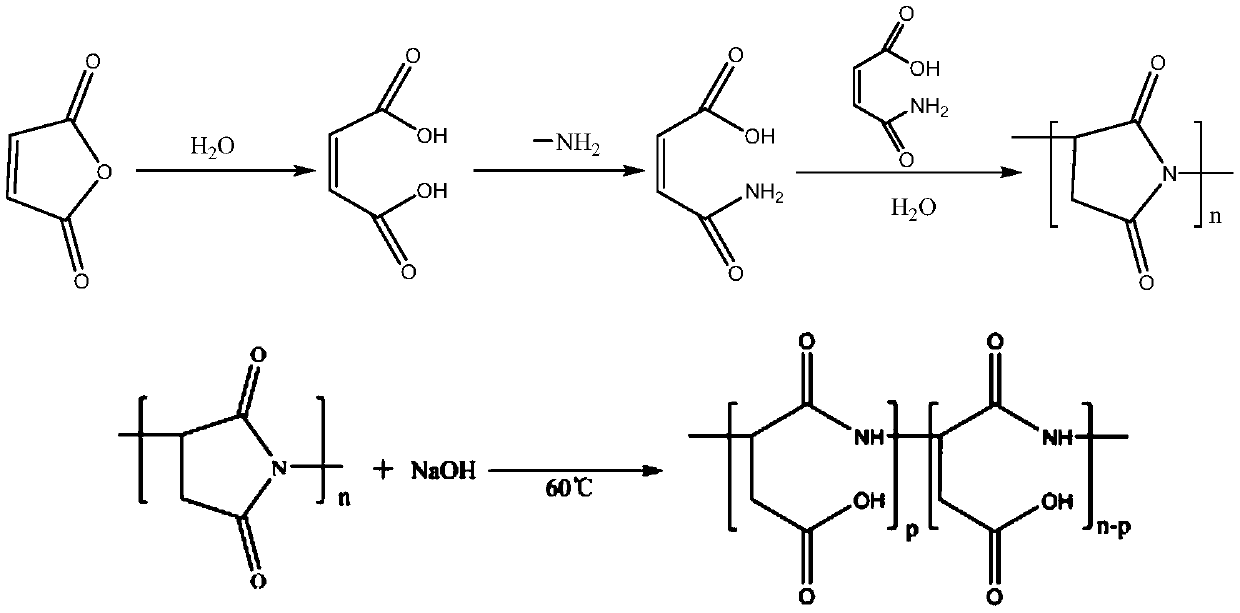

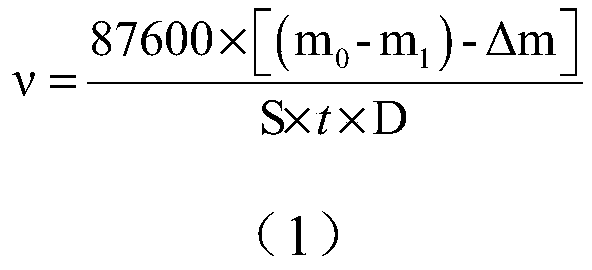

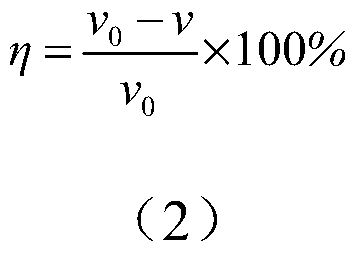

Method used

Image

Examples

Embodiment 1

[0026] A compound low-phosphorus corrosion inhibitor suitable for oilfield systems, which consists of polyaspartic acid aqueous solution, polyamino polyether group methylene phosphonic acid aqueous solution, N-(3-aminopropyl) imidazole aqueous solution, zinc sulfate aqueous solution Prepared according to the volume ratio of 1:1:1:1;

[0027] Wherein, the concentration of polyaspartic acid aqueous solution is 10mg / L, the concentration of polyaminopolyether group methylene phosphonic acid aqueous solution is 5mg / L, the concentration of N-(3-aminopropyl) imidazole aqueous solution is 50mg / L, The concentration of the zinc sulfate aqueous solution is 2 mg / L.

[0028] The preparation method of this composite low phosphorus corrosion inhibitor specifically carries out according to the following steps:

[0029] Step 1, preparation concentration is the polyaspartic acid aqueous solution of 10mg / L, the polyamino polyether group methylene phosphonic acid aqueous solution that concentrat...

Embodiment 2

[0039] A compound low-phosphorus corrosion inhibitor suitable for oilfield systems, which consists of polyaspartic acid aqueous solution, polyamino polyether group methylene phosphonic acid aqueous solution, N-(3-aminopropyl) imidazole aqueous solution, zinc sulfate aqueous solution Prepared according to the volume ratio of 1:1:1:1;

[0040] Wherein, the concentration of polyaspartic acid aqueous solution is 50mg / L, the concentration of polyaminopolyether group methylene phosphonic acid aqueous solution is 25mg / L, the concentration of N-(3-aminopropyl) imidazole aqueous solution is 50mg / L, The concentration of zinc sulfate aqueous solution is 10mg / L.

[0041] The preparation method of this composite low phosphorus corrosion inhibitor specifically carries out according to the following steps:

[0042] Step 1, preparation concentration is respectively the polyaspartic acid aqueous solution of 50mg / L, the polyamino polyether group methylene phosphonic acid aqueous solution that ...

Embodiment 3

[0052] A compound low-phosphorus corrosion inhibitor suitable for oilfield systems, which consists of polyaspartic acid aqueous solution, polyamino polyether group methylene phosphonic acid aqueous solution, N-(3-aminopropyl) imidazole aqueous solution, zinc sulfate aqueous solution Prepared according to the volume ratio of 1:1:1:1;

[0053] The concentration of polyaspartic acid aqueous solution is 30mg / L, the concentration of polyaminopolyether group methylene phosphonic acid aqueous solution is 25mg / L, the concentration of N-(3-aminopropyl) imidazole aqueous solution is 40mg / L, zinc sulfate The concentration of the aqueous solution was 4mg / L.

[0054] The preparation method of this composite low phosphorus corrosion inhibitor specifically carries out according to the following steps:

[0055] Step 1, preparation concentration is respectively the polyaspartic acid aqueous solution of 30mg / L, the polyamino polyether group methylene phosphonic acid aqueous solution that conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com