Part loading device

A technology of parts and controllers, which is applied in the field of loading devices, can solve the problems that parts cannot be put in smoothly, the line stops, and the production capacity of the line body is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0032] In addition, the terms "first, second, third, fourth" etc. mentioned in this embodiment are for the convenience of description and do not constitute a limitation to this embodiment. The azimuth nouns such as left, right, upper, and lower involved in this embodiment are also based on terms in the illustrated state for the convenience of description, and should not be construed as limiting the structures described in this embodiment.

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

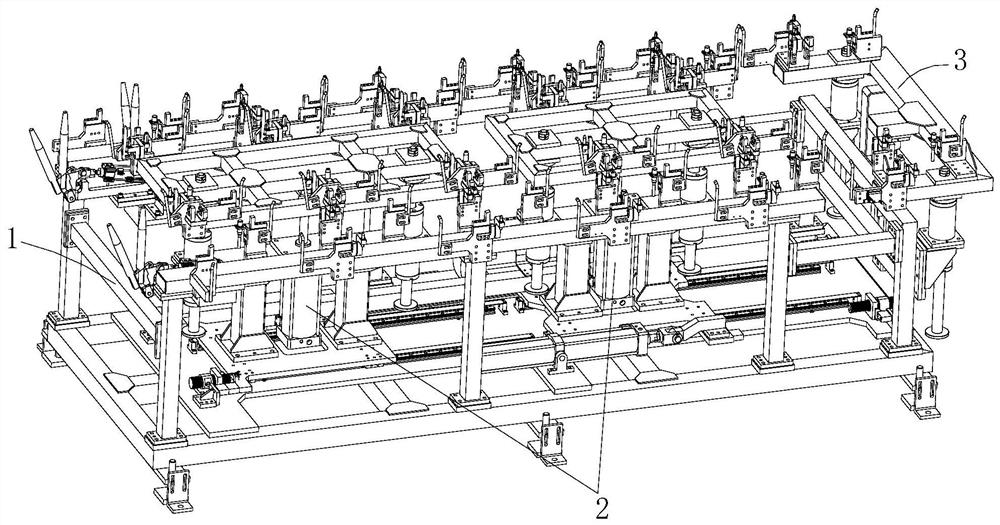

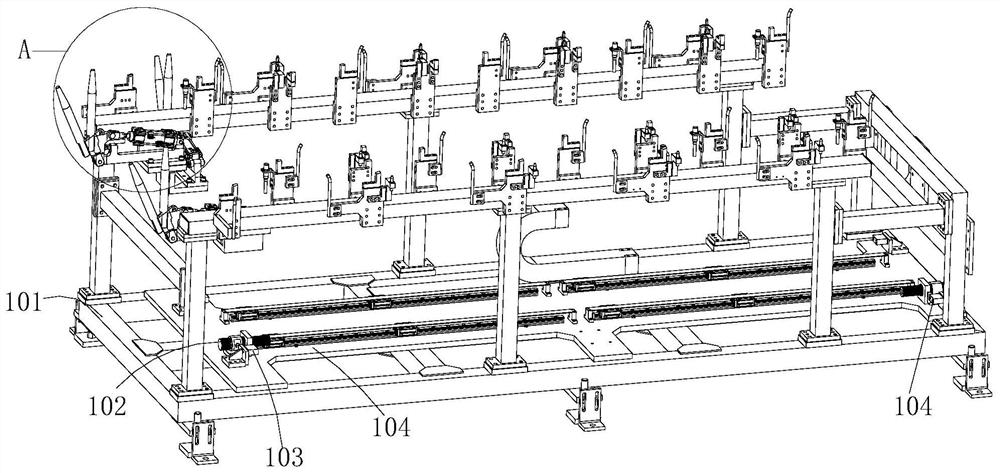

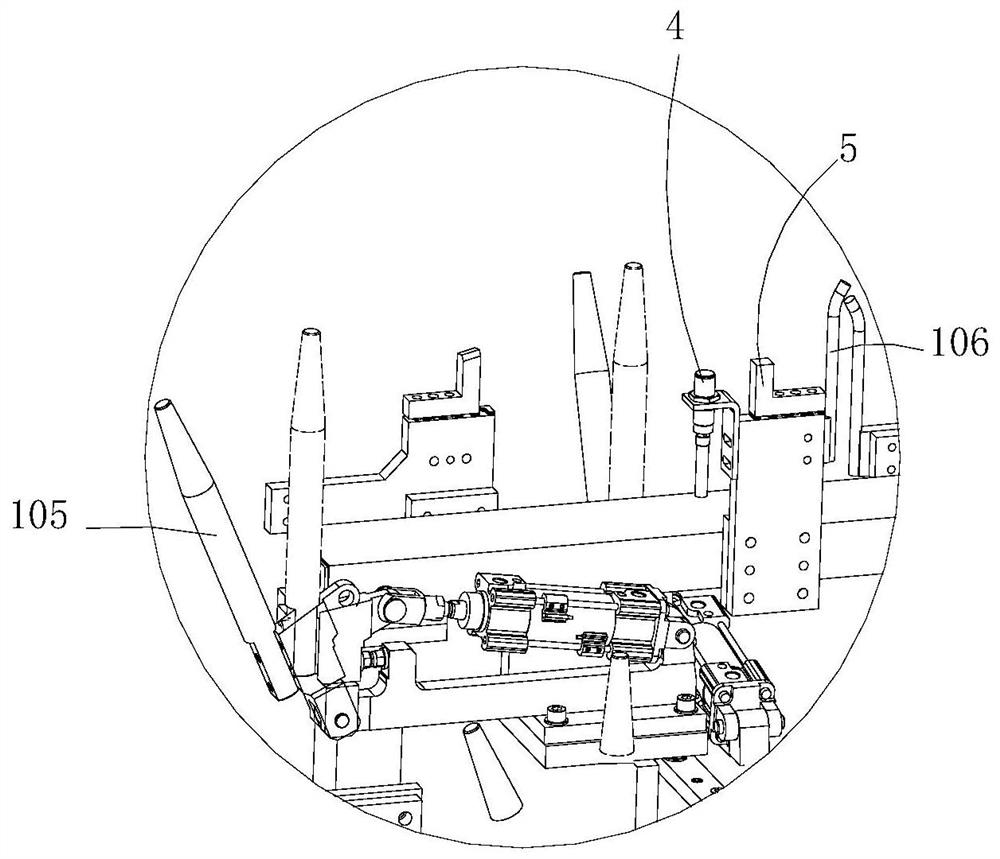

[0034] This embodiment relates to a device for loading a workpiece, the overall structure of which includes a controller, a fixing mechanism for guiding and positioning the workpiece, a moving mechanism for driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com