Automatic take-up and loading device for winder

An automatic material receiving and winding machine technology, applied in battery assembly machines, sustainable manufacturing/processing, electrochemical generators, etc., can solve problems such as low automation, high labor intensity of employees, and affecting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

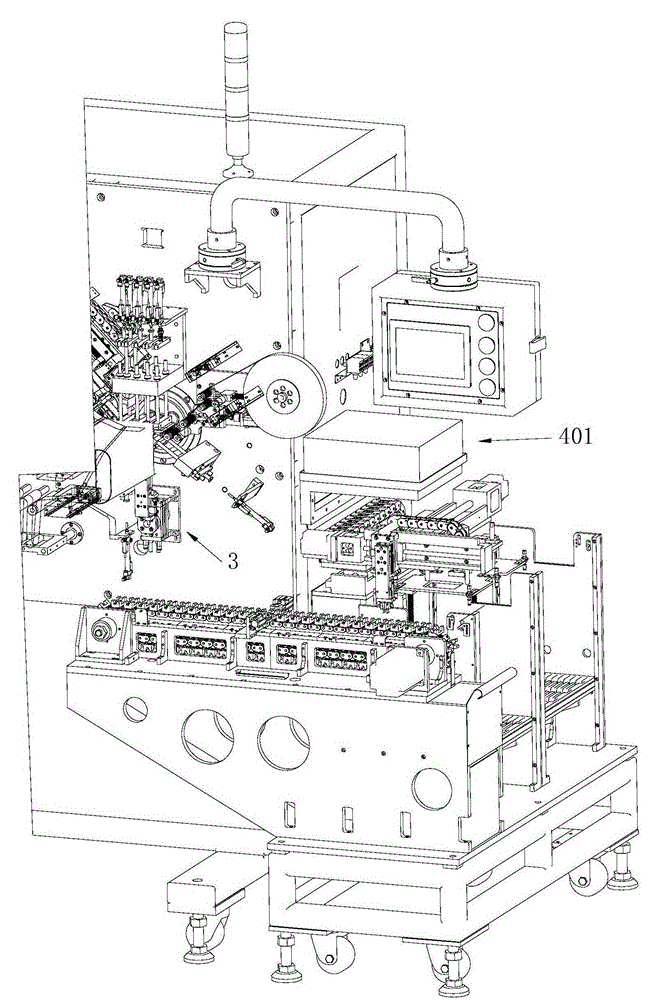

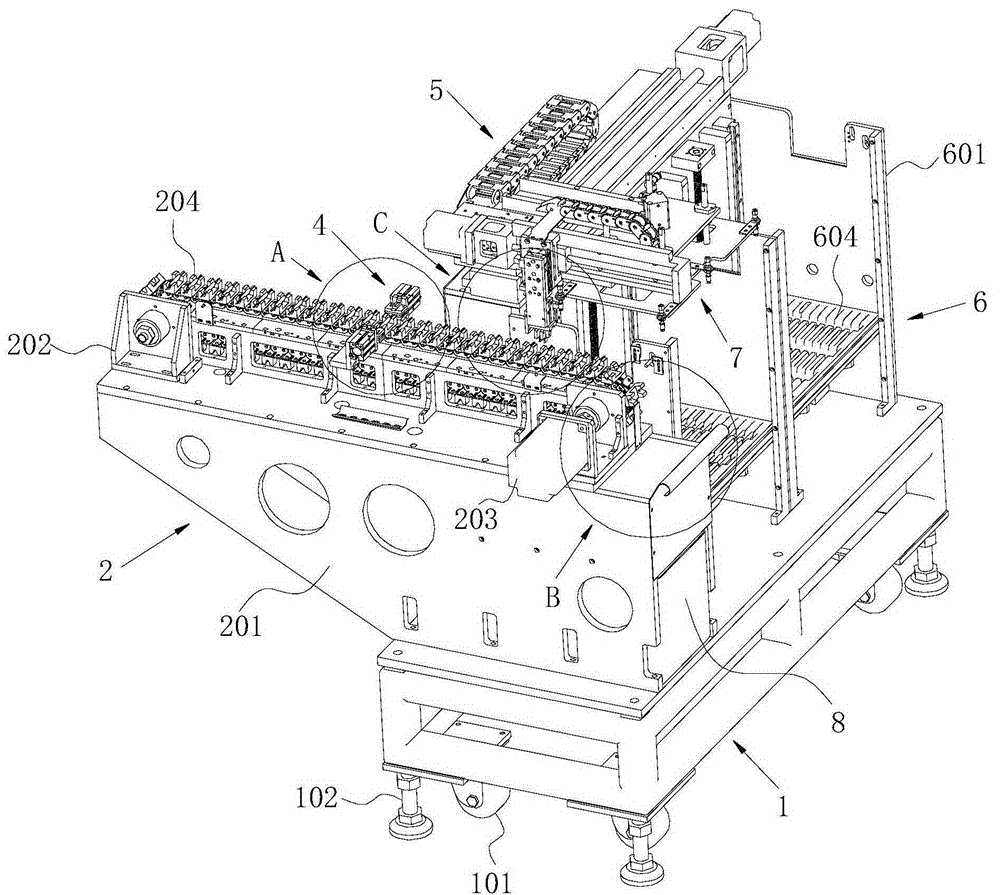

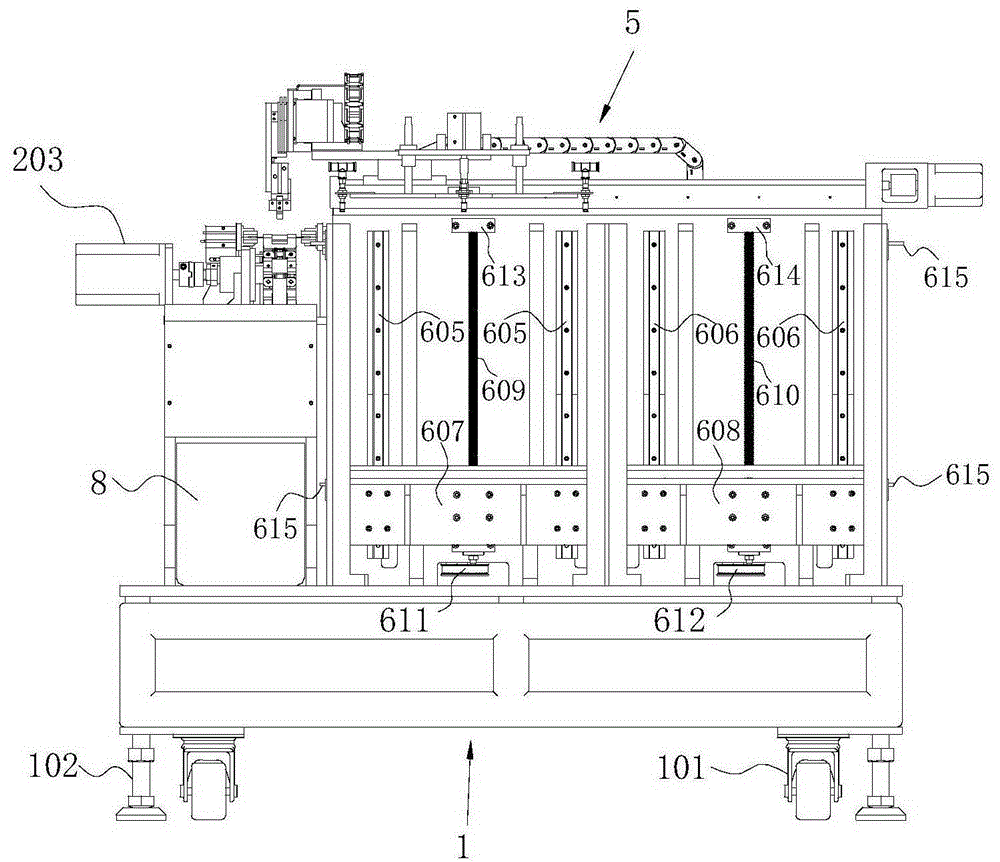

[0074] Such as Figure 1-18 As shown, in this embodiment, an automatic material receiving and loading device for a winding machine includes a winding machine body, a horizontal conveying mechanism 2, a material receiving manipulator 5, a suction cup mechanism 7, a material tray mechanism 6 and a base 1, The horizontal conveying mechanism 2 and the material tray mechanism 6 are all fixed on one side of the base 1, and the side of the base 1 away from the material tray mechanism 6 is provided with a pulley 101 and a liftable support foot 102, and the support foot 102 is provided with a rotating screw thread to Rotating the supporting foot 102 in one direction can make it stretch, and rotating the supporting foot 102 in the other direction can make it shorten. Keep the pulley 101 off the ground to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com