Glass production line for loading and unloading sheets fully automatically

A glass production line, fully automatic technology, applied in the direction of conveyor objects, furnaces, conveyors, etc., can solve the problems of affecting the work efficiency of glass edging line, reducing the qualified rate of glass, and high labor intensity of workers, so as to improve the efficiency of loading, The effect of improving the safety of loading and reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

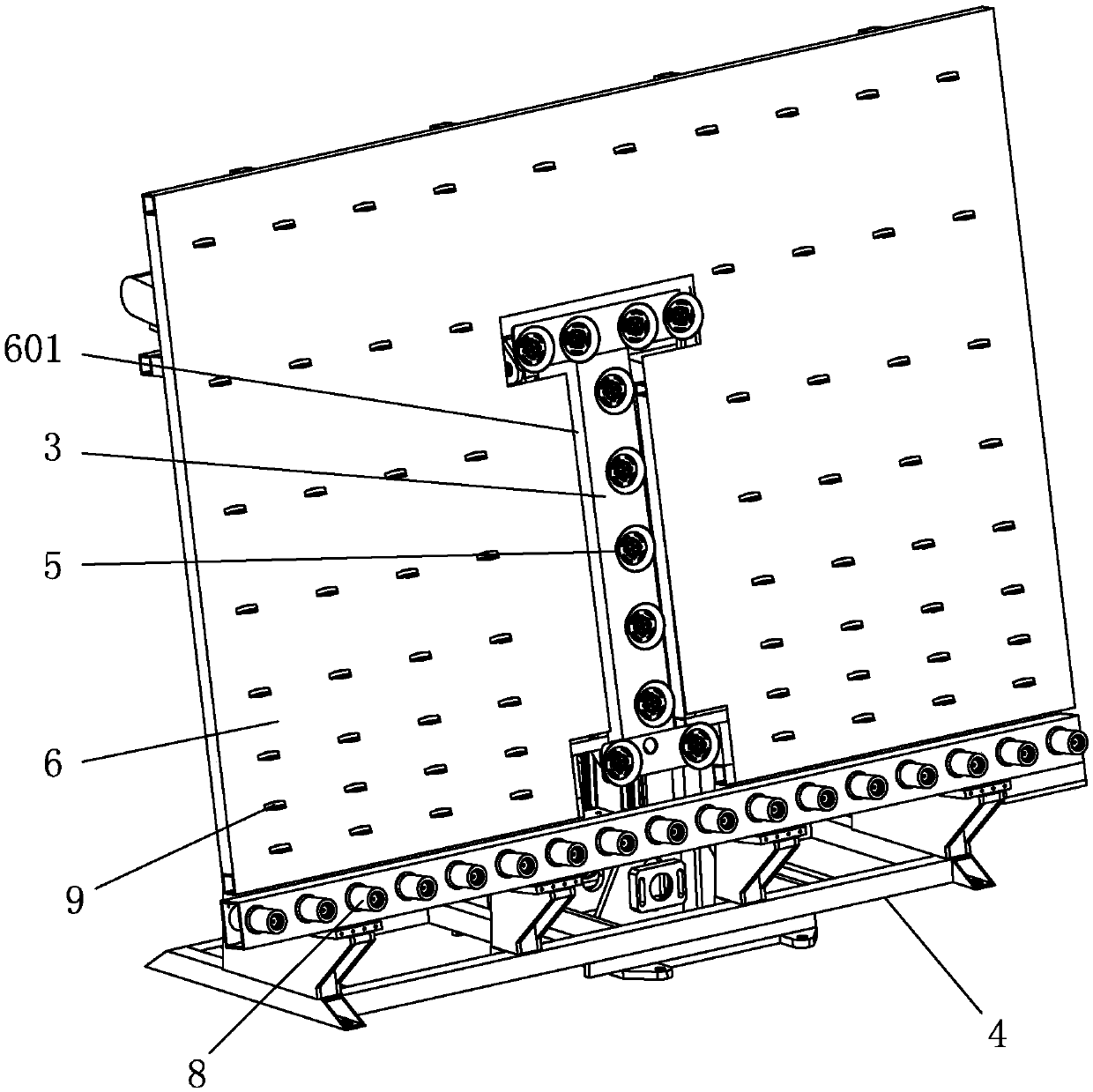

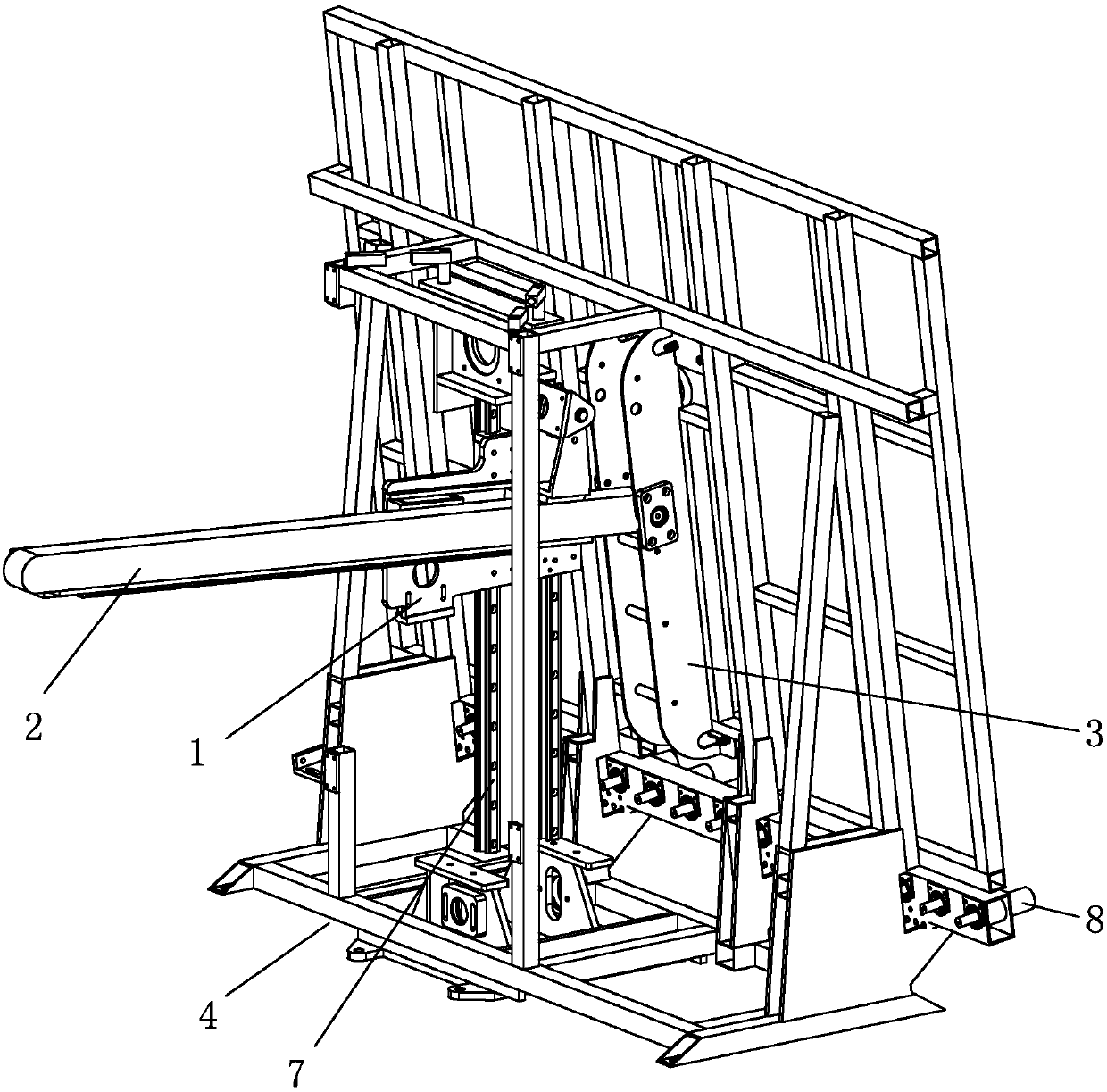

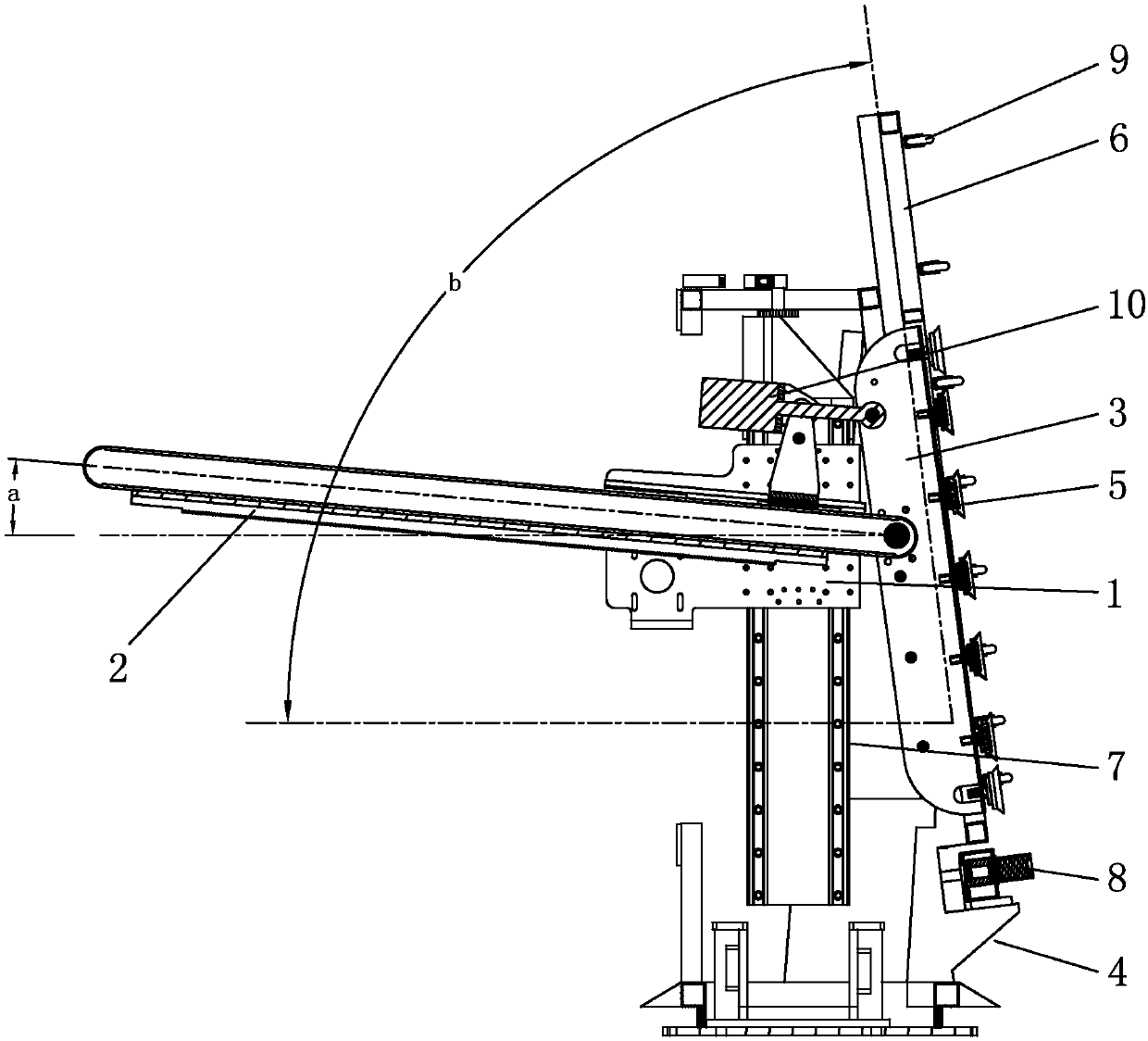

[0028] see Figure 1-Figure 4 , this automatic glass production line for loading and unloading, including glass loading machine, glass processing equipment and glass unloading machine, wherein, the glass loading machine is set at the feeding end of the glass processing equipment, and the glass unloading machine is set at the same At the unloading end, the glass loader and glass unloader are seamlessly connected with the glass processing equipment to ensure the continuity of the glass production line and realize fully automated production, thereby improving work efficiency and meeting production requirements; and the entire production process does not require The participation of workers greatly reduces the labor intensity of workers, and one person can take care of multiple production lines, reducing labor costs;

[0029] in,

[0030] The glass loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com