Thermoelectric cooling device of inter-tube flowing working medium, with combination of flexible panel heat tube

A flat heat pipe and thermoelectric cooling technology, which is applied in the direction of refrigerators, indirect heat exchangers, heat exchange equipment, etc., can solve the problem of cooling of flowing working fluid, etc., and achieve the effect of easy disassembly and carrying, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

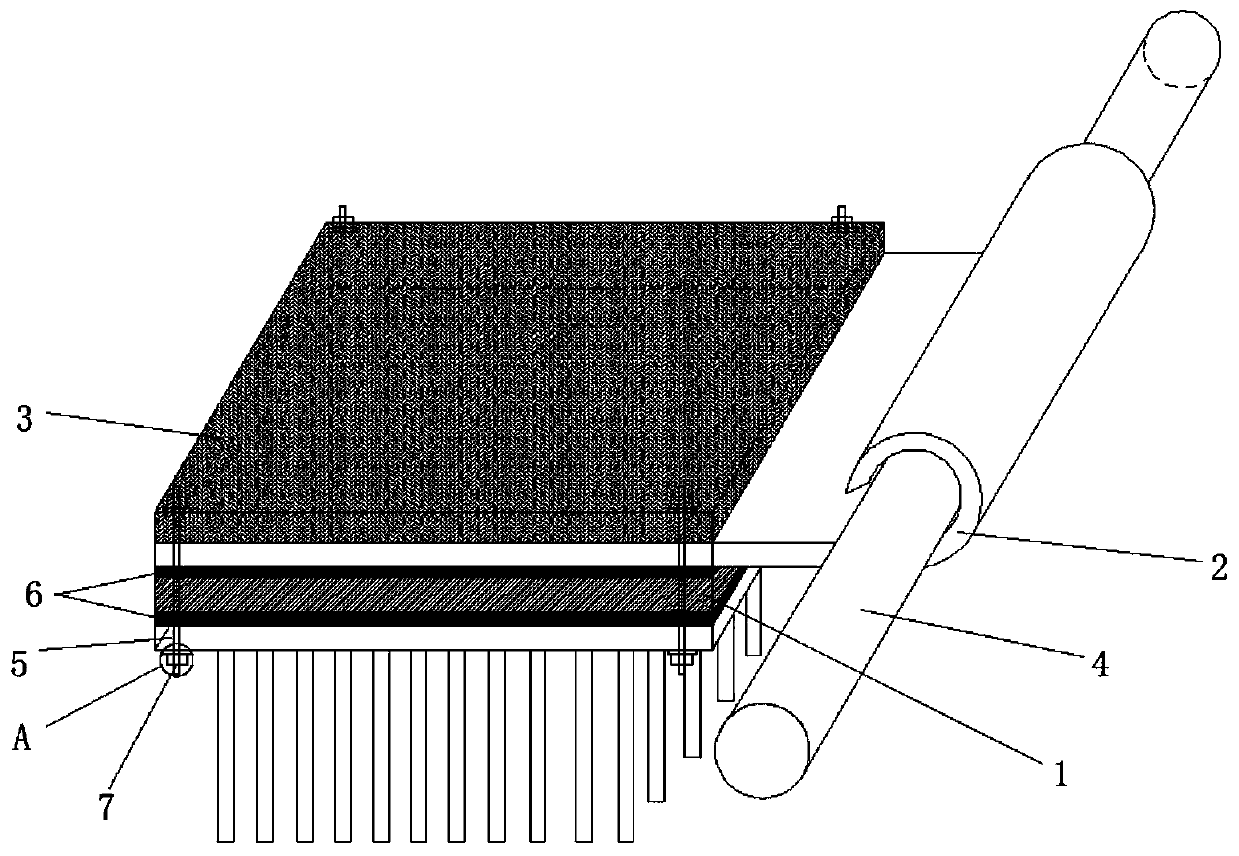

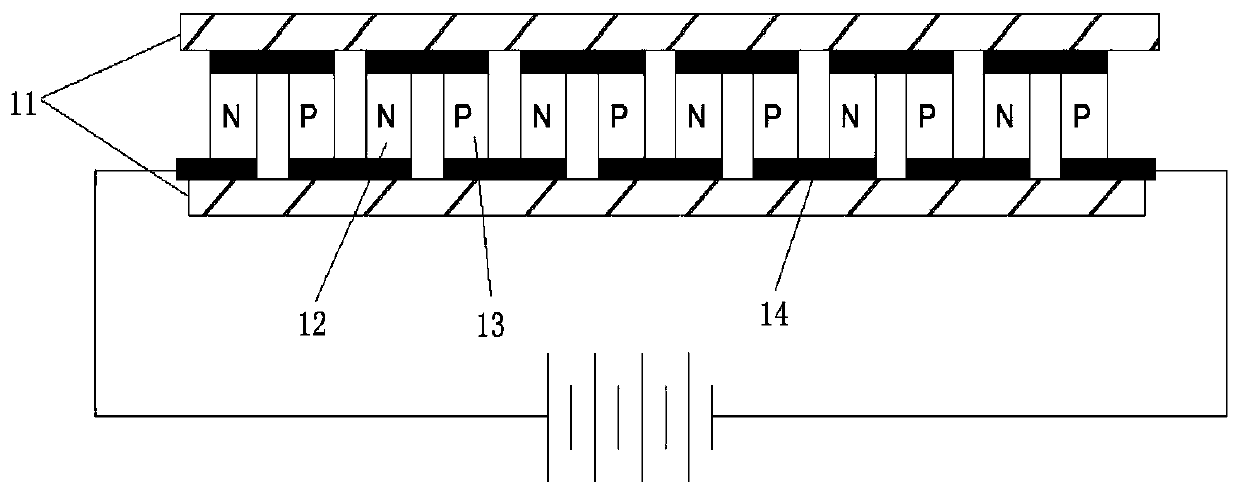

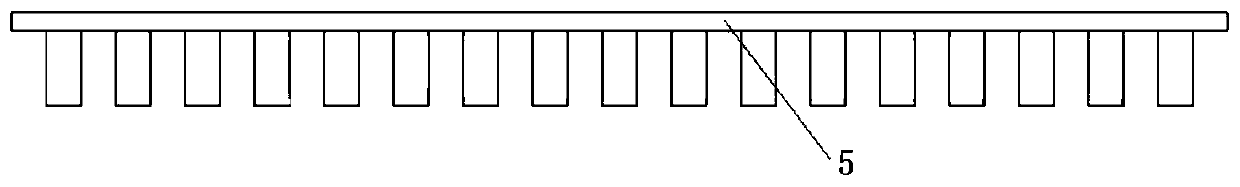

[0024] Such as figure 1 As shown, the present invention is a thermoelectric cooling device for working medium flowing in a tube combined with a flexible flat heat pipe, including a thermoelectric cooling sheet 1, the cold end of the thermoelectric cooling sheet 1 is attached to the lower surface of the condensation end of the flexible flat heat pipe 2, and the flexible flat heat pipe 2 The upper surface of the condensing end is bonded with a thermal insulation plate 3; one end of the flexible flat heat pipe 2 extends out of the thermoelectric cooling sheet 1 and the protruding end of the flexible flat heat pipe 2 has a curved structure, and the curved structure of the flexible flat heat pipe 2 is in line with the The copper pipe 4 is clamped and fixed, and the flexible flat heat pipe 2 can efficiently cool the working medium in the copper pipe 4; at the same time, the bending curvature of the curved structure of the flexible flat heat pipe 2 is set to be the same as that of the...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the cold end and the hot end of the thermoelectric cooling sheet 1 are reversed, that is, only the direction of the current in the thermoelectric cooling sheet 1 needs to be changed without disassembling the device. The present invention can be used for heating the copper pipe 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com