Large-flow muddy water lifting watercart

A large flow, water wheel technology, applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve problems such as debris blockage, inconvenient maintenance and troubleshooting, etc., to achieve stable transmission, large contact area, and good transmission effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

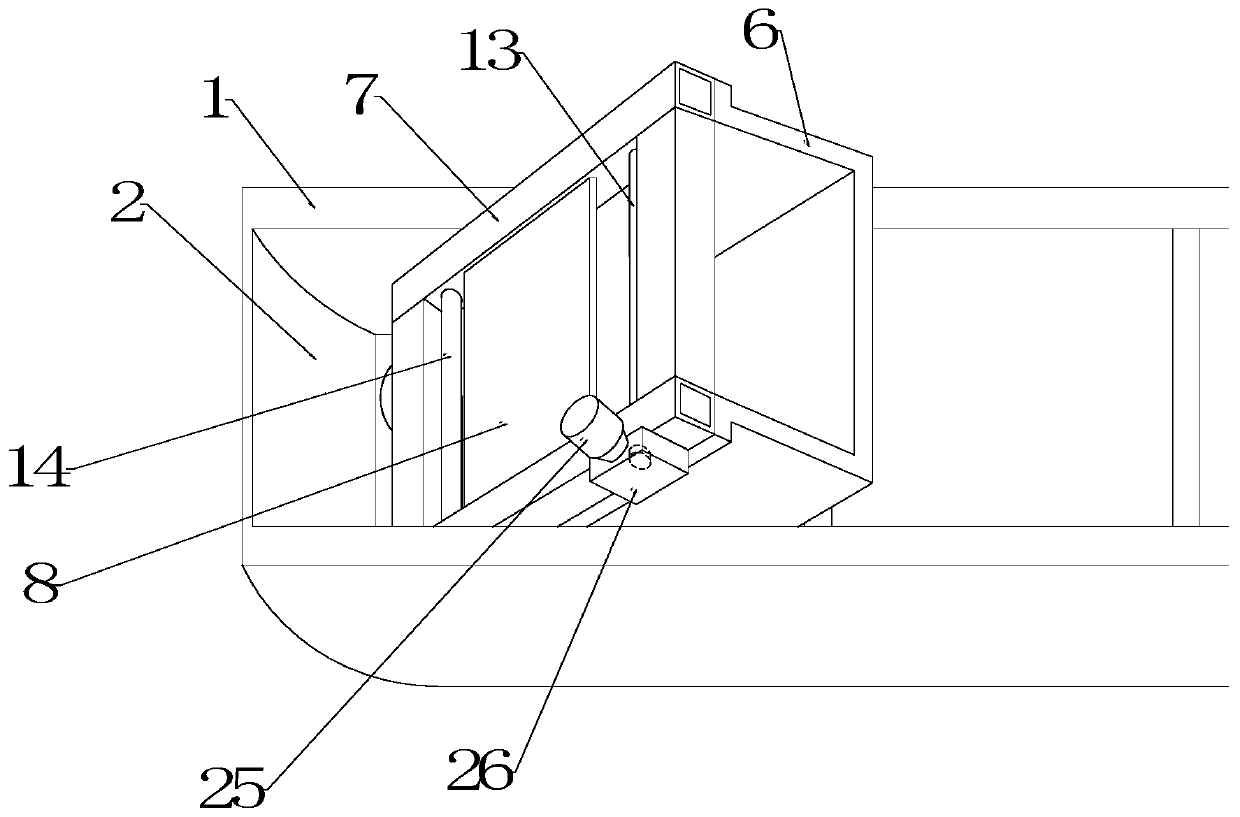

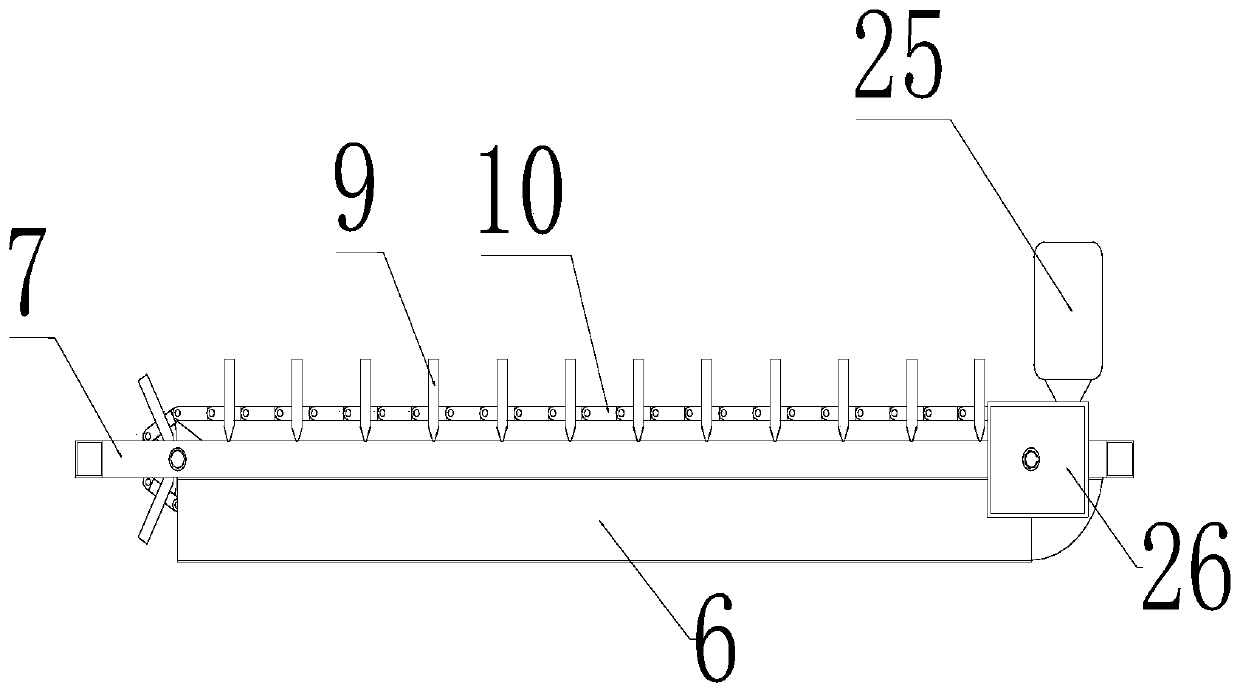

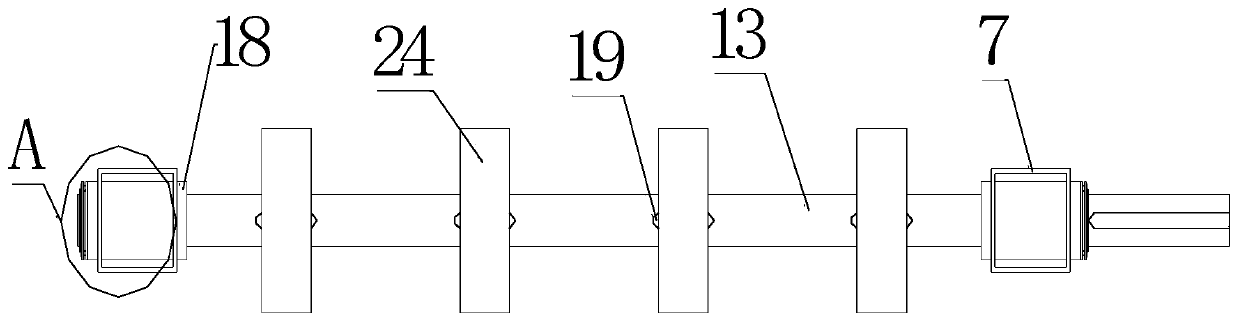

[0029] Example: such as Figure 1-10 As shown, a large-flow muddy water lifting water truck includes a carrier 1, a negative pressure cabin 2, a suction assembly 3, a transmission device 4, and a power device 5. The rear end of the carrier 1 is welded with a negative pressure cabin 2, and the negative pressure cabin 2 is welded with the water tank 6 of the drawing assembly 3, the fixed frame 7 of the drawing assembly 3 is welded with the bearing shell 18 of the transmission device 4, and the drive shaft 13 of the transmission device 4 is axially connected with the reducer 26 of the power device 5.

[0030]The extraction assembly 3 includes a water tank 6 and a fixed frame 7, the lower end of the water tank 6 is welded to the negative pressure cabin 2, and the upper end of the water tank 6 is welded with a fixed frame 7; the transmission device 4 includes a driving shaft 13, a driven shaft 14, a gear 24, and a bearing housing 18 , a gear 24 is fixed on the driving shaft 13 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com