A new type of environmentally friendly high-barrier direct-coated paper and its preparation process

A high-barrier, direct-plating technology, applied in the field of packaging, can solve the problems of complicated process, difficult to achieve industrial production, and inability to obtain coating at one time, and achieve the effect of rich colors and improved barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

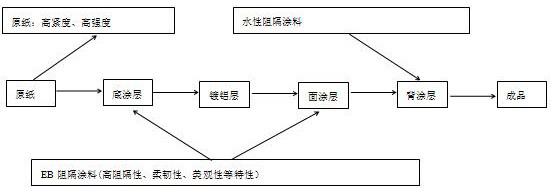

Method used

Image

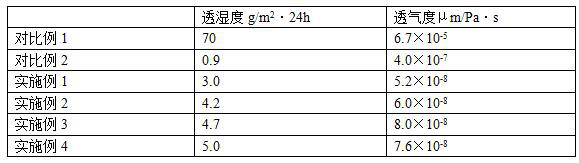

Examples

Embodiment 1

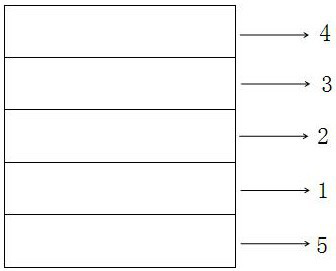

[0049] A new type of environmentally friendly high-barrier direct-coated paper includes a back coat layer 5, a base paper layer 1, an undercoat layer 2, an aluminum-coated layer 3, and a top coat layer 4 arranged in sequence. The production process includes the following steps:

[0050] (1) The quantification is 50g / m², and the tightness is 1.2g / cm 3 The base paper is coated with an electron beam cured coating on a high-speed coating machine (the formula is calculated by weight ratio: 35 parts of hyperbranched polyester acrylate, 35 parts of polyurethane acrylate, 20 parts of IOBA, 10 parts of HDDA, and 0.01 part of silicone resin). The primer barrier layer is formed by electron beam radiation curing, the temperature of the material is controlled at 45±2°C, the viscosity of Caien 3# cup is 20 seconds, the speed is 200m / min, the curing dose is 10KGy, and the coating amount is 1.0g / m 2 ;

[0051] (2) The dried paper is aluminized by vacuum evaporation, the square resistance val...

Embodiment 2

[0056] A new type of environmentally friendly high-barrier direct-coated paper includes a back coat layer 5, a base paper layer 1, an undercoat layer 2, an aluminum-coated layer 3, and a top coat layer 4 arranged in sequence. The production process includes the following steps:

[0057] (1) The quantification is 80g / m², and the tightness is 1.1g / cm 3 The base paper is coated with an electron beam cured coating on a high-speed coating machine (formula: 40 parts of hyperbranched polyester acrylate, 30 parts of polyurethane acrylate, 15 parts of IOBA, 15 parts of HDDA, and 0.01 part of polyacrylate), formed by electron beam radiation Primer barrier layer, the temperature of the material is controlled at 45±2°C, the viscosity of Caien 3# cup is 23 seconds, the speed is 600m / min, the curing amount is 20KGy, and the coating amount is 1.5g / m²;

[0058] (2) The dried paper is aluminized by vacuum evaporation, the resistance value of the aluminum layer is 0.45 square ohms, and the spee...

Embodiment 3

[0063] A new type of environmentally friendly high-barrier direct-coated paper includes a back coat layer 5, a base paper layer 1, an undercoat layer 2, an aluminum-coated layer 3, and a top coat layer 4 arranged in sequence. The production process includes the following steps:

[0064] (1) The quantification is 100g / m², and the tightness is 1.1g / cm 3 The base paper is coated with an electron beam cured coating on a high-speed coating machine (formula: 45 parts of hyperbranched polyester acrylate, 25 parts of polyurethane acrylate, 10 parts of IOBA, 20 parts of HDDA, and 0.05 parts of polyacrylate), formed by electron beam radiation Primer barrier layer, material temperature controlled at (25±2)°C, T4 cup viscosity 22 seconds, vehicle speed 800m / min, coating amount 2g / m²; curing dose 30KGy

[0065] (2) The dried paper is aluminized by vacuum evaporation, the square resistance value of the aluminum layer is 0.6 ohms, and the speed is 15m / s.

[0066] (3) Topcoat the aluminized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com