Microwave absorbing body based on YIG thin film material and preparation method thereof

A technology of microwave absorption and thin film materials, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of complex process, harsh reaction conditions, cumbersome operation process, etc., and achieve excellent microwave absorption performance and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

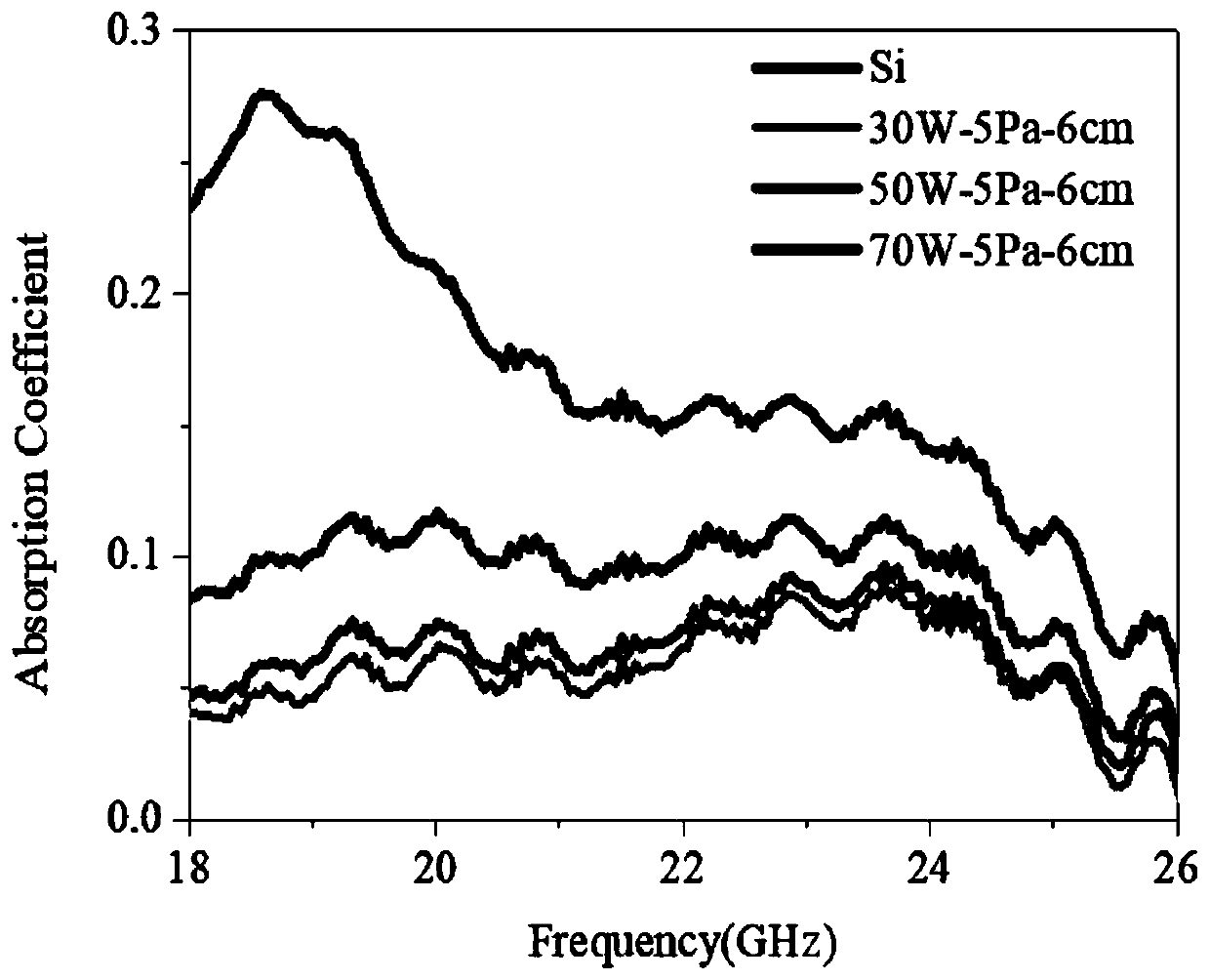

[0027] figure 1 It is a structural schematic diagram of the microwave absorbing material of the YIG film material in the method of the present invention. Such as figure 1 As shown, the microwave absorber includes: a substrate 100; a thin film 101; the thin film 101 is grown on the substrate 100, and a YIG single crystal thin film is selected in this embodiment.

[0028] The substrate 100 is a Si substrate.

[0029] The thin film 101, the YIG single crystal thin film selected by the example is a rare earth ferrimagnetic ferrite material, which belongs to the cubic crystal system, the lattice is a body-centered cubic lattice, and the lattice group type is Ia3d-O h 10 ; The structure of the crystal lattice is a structure composed of cations as the skeleton, and the metal cations of ferrite are embedded in the gap of oxygen ions.

[0030] The thin film 101 can be prepared by radio frequency magnetron sputtering, and the thickness of the thin film is about 100 nm.

[0031] Fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com