Modular intelligent irregular part operation platform

A technology for operating platforms and special-shaped parts, applied in the field of machinery and equipment, can solve the problems of inconvenient production, loss of function, and inability to continue to use, and achieve the effect of simple and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

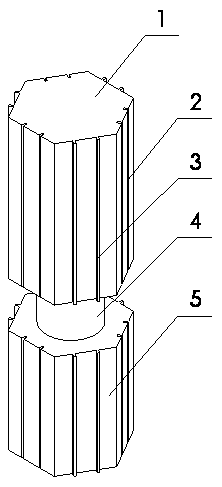

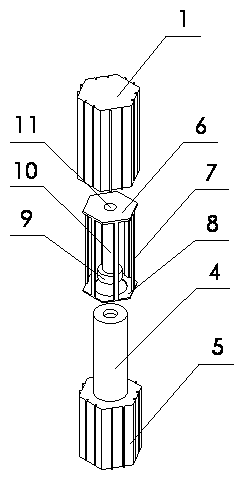

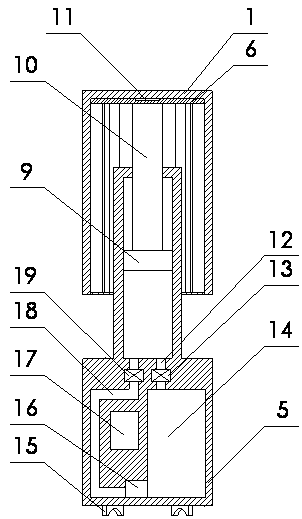

[0021] A modular intelligent special-shaped parts operating platform of the present invention is realized in the following way: a modularized intelligent special-shaped parts operating platform of the present invention is composed of a rubber leather cover (1), a sliding slot (2), a sliding insert (3), a fixed Cylinder (4), base (5), top support plate (6), side support bar (7), sliding sleeve plate (8), piston (9), push rod (10), pressure sensor (11), liquid outlet pipe (12), check valve No. 1 (13), liquid storage tank (14), foot stand (15), electric pump (16), control box (17), liquid inlet pipe (18) and No. 2 sheet One end of the fixed cylinder (4) is fixed and vertically placed on the top of the fixed base (5). The fixed base is a hexagonal prism structure, and three of the six sides of the fixed base are equipped with Sliding inserts (3), sliding slots (2) are provided on the other three sides, and one side of the adjacent two sides is a sliding insert (3), and the other i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com