Positioning mechanism for measuring cross section distortion of metal bent pipe

A technology of positioning mechanism and pipe bending, which is applied in the direction of metal processing, metal processing equipment, workpiece clamping device, etc., can solve the problems of bending pipe section distortion, low precision, high cost, etc., and achieve guaranteed levelness, high positioning accuracy, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

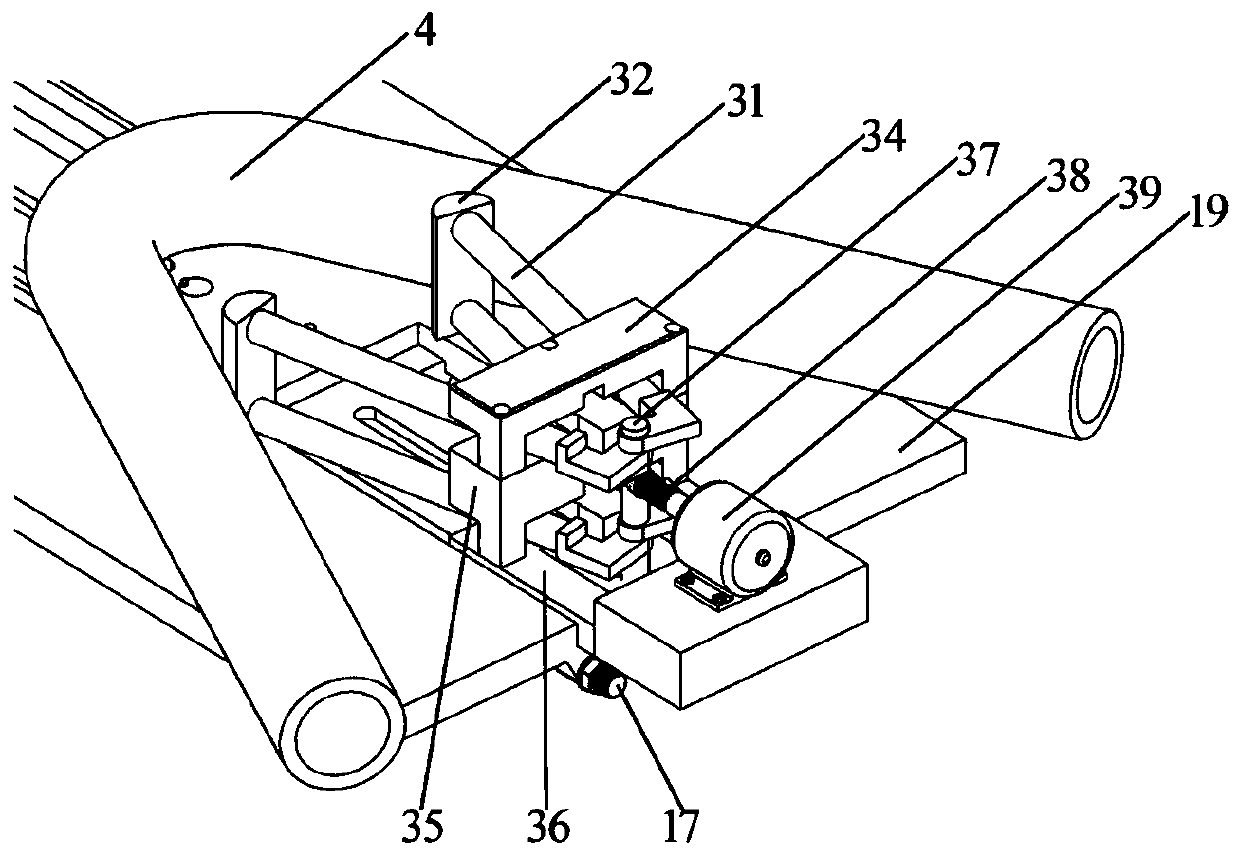

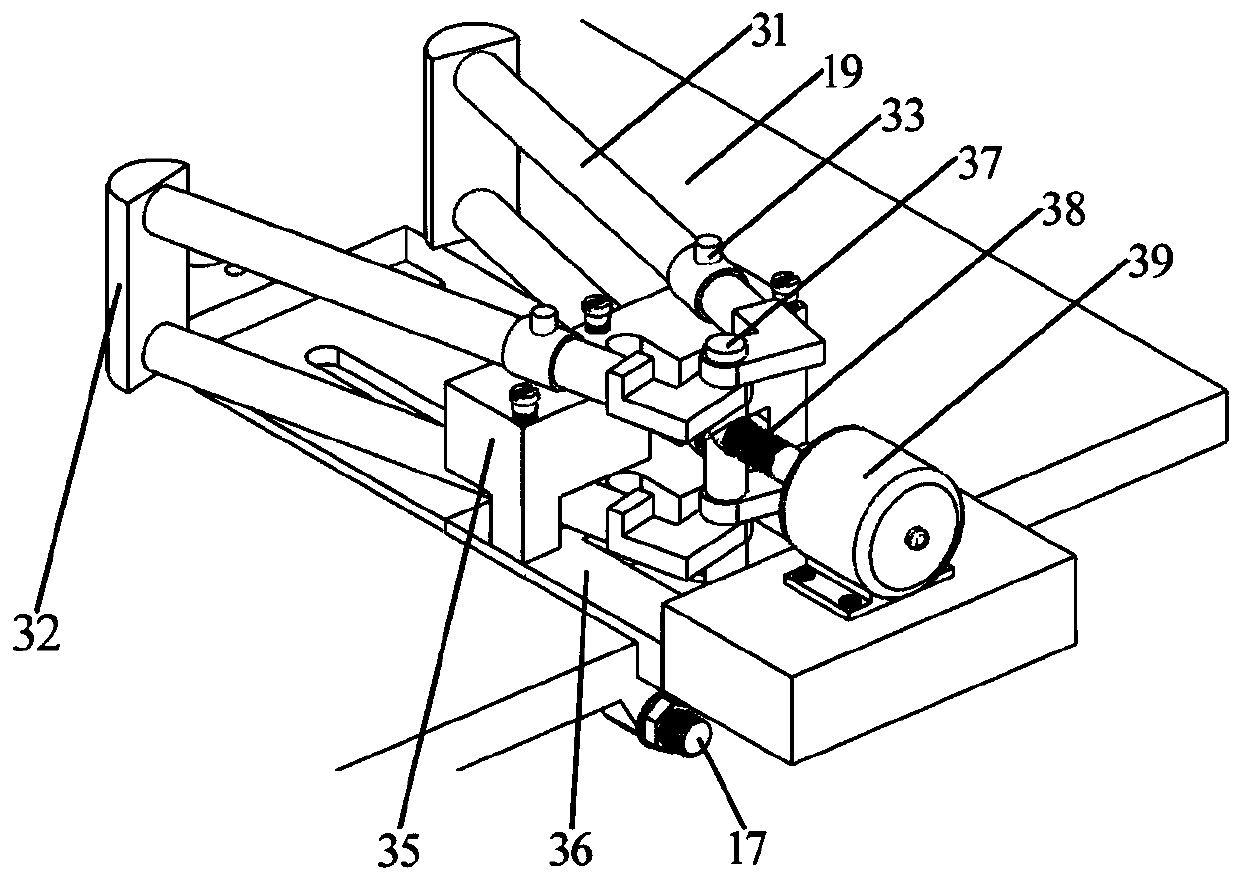

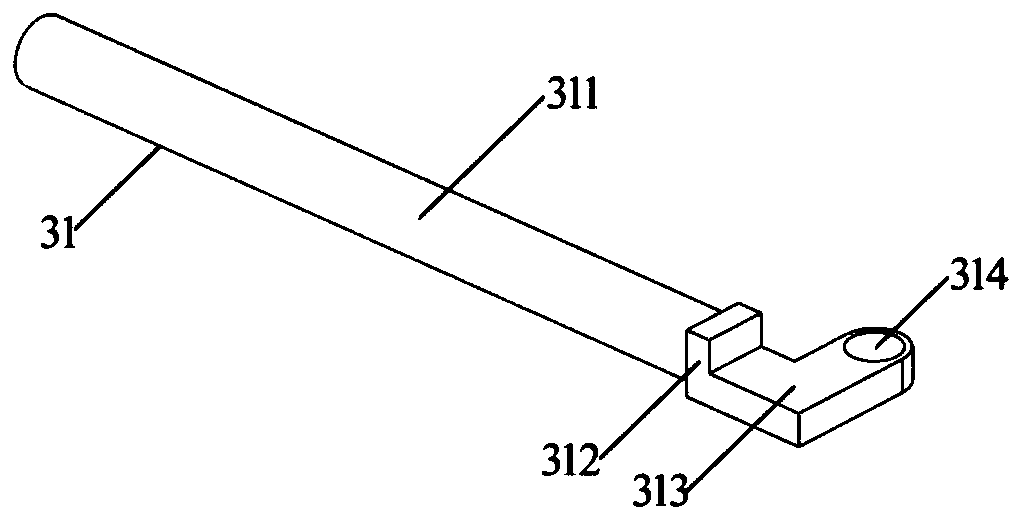

[0030] A positioning mechanism for measuring cross-sectional distortion of a metal elbow of this embodiment, such as Figure 1-10 As shown, a bottom plate 19 is included. A mounting plane 191 is opened on the bottom plate 19, and an adjusting slider 36 is installed on the mounting plane 191; a lower cover 35 is installed on the adjusting slider 36; A pair of positioning support rods 31 are installed between the adjusting slider 36 and the lower cover plate 35; the upper cover plate 34 is installed on the lower cover plate 35; the lower cover plate 35 and the upper cover plate 34 are also A pair of positioning support rods 31 are installed; a positioning support rod 31 between the adjusting slider 36 and the lower cover 35, a positioning support between the lower cover 35 and the upper cover 34 A positioning top rod 32 is installed between the rods 31, the other positioning support rod 31 between the adjusting slider 36 and the lower cover 35, and the other between the lower cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com