Extraction process for heatable but non-combustible cigarette plant perfume material

A heat-not-burn, plant-flavored technology, applied in essential oils/spices, tobacco, food science, etc., can solve problems such as ineffective effects, and achieve the effects of improving consumption experience, high degree of reduction, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

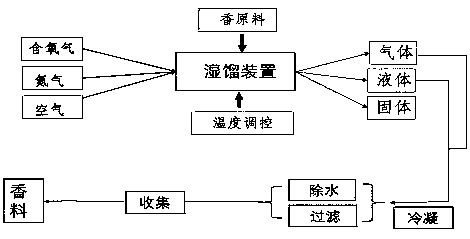

Method used

Image

Examples

Embodiment 1

[0022] Grind the tobacco raw material with a mesh number of 60 mesh, add 0.7 times of water to the tobacco plant powder, mix evenly, then place the tobacco plant water powder in a wet distillation device, and heat it at 50~130°C, 130~240°C, 240~350℃, 350~500℃ 4 different temperature gradient heating cracking, the wet distillation time of each temperature section is 90min, the air flow rate is 0.3cm / s, the height difference between the inlet and outlet is 6cm , At the outlet of the device, the gas and liquid are condensed at 3°C to collect the product, and the flavor suitable for heat-not-burn cigarettes is obtained.

[0023] The heat-not-burn fragrance prepared in this example was added to MC pods for sensory evaluation using MC smoking utensils, and then the sensory evaluation test was carried out according to the method described in the specification of this application, and the test results are listed in Table 1 below.

Embodiment 2

[0025] Grind the mint raw material, the mesh number is 50 mesh, add 0.6 times of water to the mint plant powder, mix evenly, and then put the mint plant water powder in a wet distiller, at 50~130°C, 130~240°C, 240~350℃, 350~500℃ 4 different temperature gradient heating cracking, the wet distillation time of each temperature section is 90min, the air flow rate is 0.4cm / s, the height difference between the inlet and outlet is 5cm , At the outlet of the device, the gas and liquid are condensed at 2°C to collect the product, and the flavor suitable for heat-not-burn cigarettes is obtained.

[0026] The heat-not-burn fragrance prepared in this example was added to MC pods for sensory evaluation using MC smoking utensils, and then the sensory evaluation test was carried out according to the method described in the specification of this application, and the test results are listed in Table 1 below.

Embodiment 3

[0028] Crush the coffee raw material, the mesh number is 55 mesh, add 0.6 times of water to the coffee plant powder, mix well, then put the coffee plant water powder in the wet still, at 50~130℃, 130~240℃, 240~350℃, 350~500℃ 4 different temperature gradient heating cracking, the wet distillation time of each temperature section is 90min, the gas flow rate is 0.4cm / s oxygen, the height difference between the inlet and outlet is 8cm , At the outlet of the device, the gas and liquid are condensed at 4°C to collect the product, and the flavor suitable for heat-not-burn cigarettes is obtained.

[0029] The heat-not-burn fragrance prepared in this example was added to MC pods for sensory evaluation using MC smoking utensils, and then the sensory evaluation test was carried out according to the method described in the specification of this application, and the test results are listed in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com