Processing method for counterbore type PCB

A technology of PCB board and processing method is applied in the processing field of countersunk hole type PCB board, which can solve the problems of increasing the assembly volume of the whole machine and reducing the thickness, and achieves the effect of small assembly volume and smooth installation of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

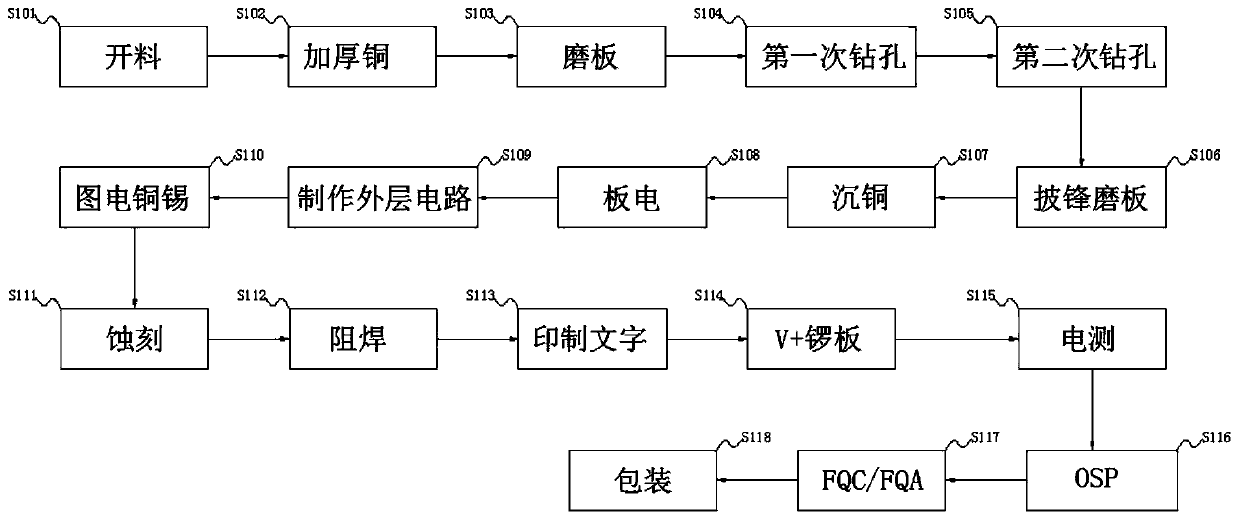

Image

Examples

Embodiment Construction

[0024] Those skilled in the art understand that, as mentioned in the background art, when the PCB board in the prior art is assembled with electronic components, it will form protrusions and increase the assembly volume of the whole machine. Therefore, it is necessary to improve the structure of the circuit board so that it tends to Yu flat.

[0025] To this end, an embodiment of the present invention provides a method for processing a counterbore PCB board, including:

[0026] Thicken the copper, thicken the copper on the PCB board, and increase the thickness of the copper foil on the PCB;

[0027] For the first drilling, the circular drill bit is used to drill the thickened copper-treated PCB board, and the conduction holes and positioning holes are processed;

[0028] For the second drilling, the taper drill is used for secondary processing, and the countersink is processed;

[0029] Etching, using the step-by-step etching method, etch the front and back of the drilled PC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com