Design method of gold immersion process test board

A design method and test board technology, applied in chemical/electrolytic methods to remove conductive materials, form electrical connection of printed components, printed circuit components, etc. The problem of unreasonable selection of gold process test board to achieve the effect of improving the quality of test graphics and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A design method of an immersion gold process test board shown in this embodiment includes the following processing steps in sequence:

[0029] (1) Cutting: Cut out the core board according to the panel size 520mm×620mm. The thickness of the core board is 1.6mm (excluding the thickness of the copper layer), and the thickness of the copper layer on both surfaces of the core board is 0.33OZ.

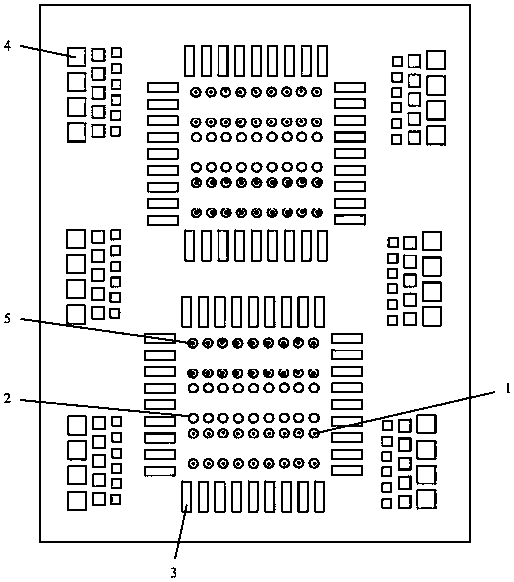

[0030] (2) Drilling: According to the existing drilling technology, several through holes 1 with a diameter of 0.1 mm are drilled on the core plate according to the design requirements (such as figure 1 shown), and the through holes are arranged in 8 rows and 9 columns on the core board.

[0031] (3) Copper sinking: A thin layer of copper is deposited on the surface of the board and the wall of the hole by the method of electroless copper deposition. The backlight test is grade 10, and the thickness of the copper sinking in the hole is 0.3 μm.

[0032] (4) Full-board electroplating:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com