Wavelength conversion component and laser light source

A technology of wavelength conversion and components, applied in optics, instruments, projection devices, etc., can solve the problems of not meeting the conditions of high-power laser use, low thermal conductivity of silica gel, low thermal conductivity, etc., to ensure thermal stability and light conversion efficiency , Guaranteed heat exchange efficiency and high light conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

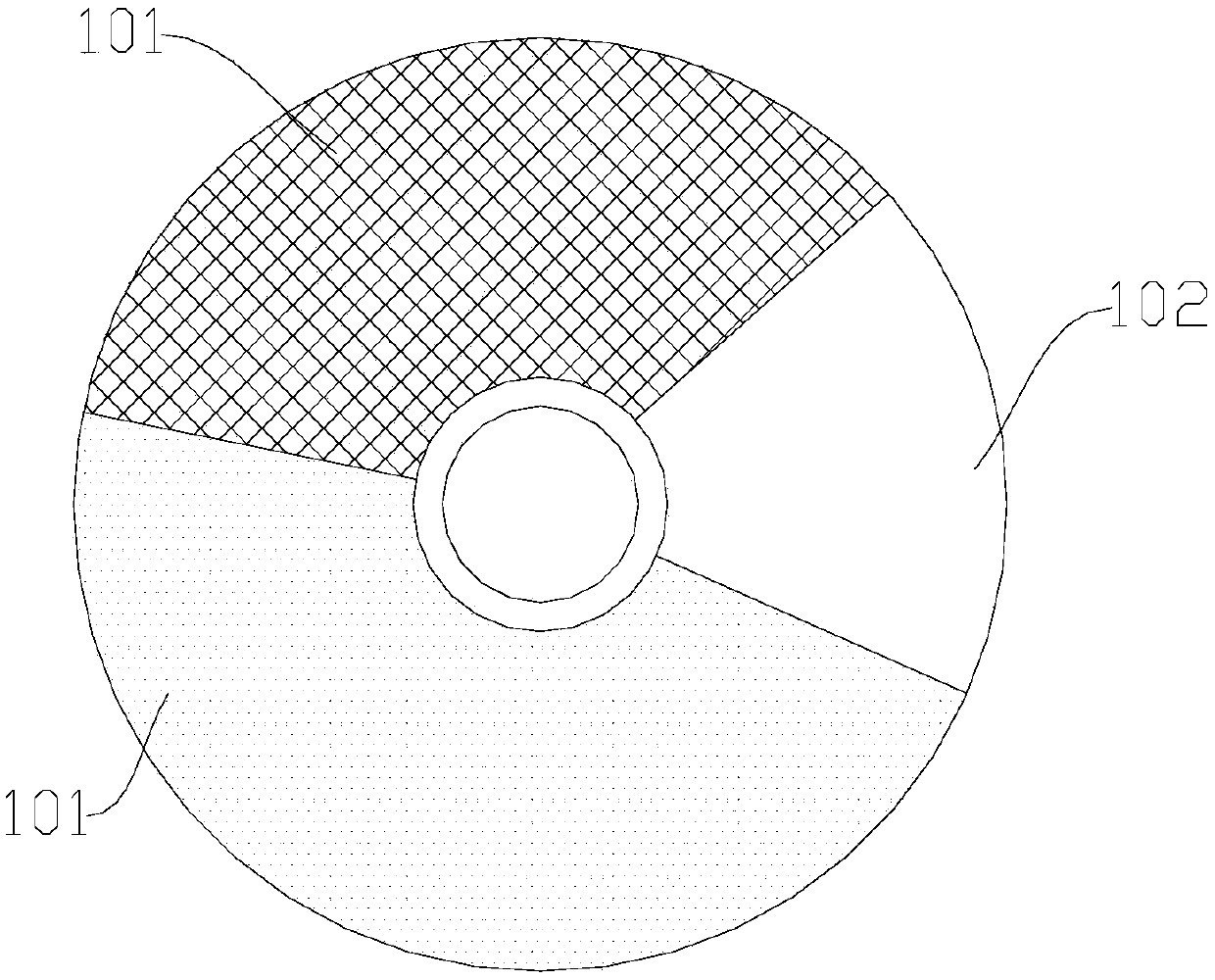

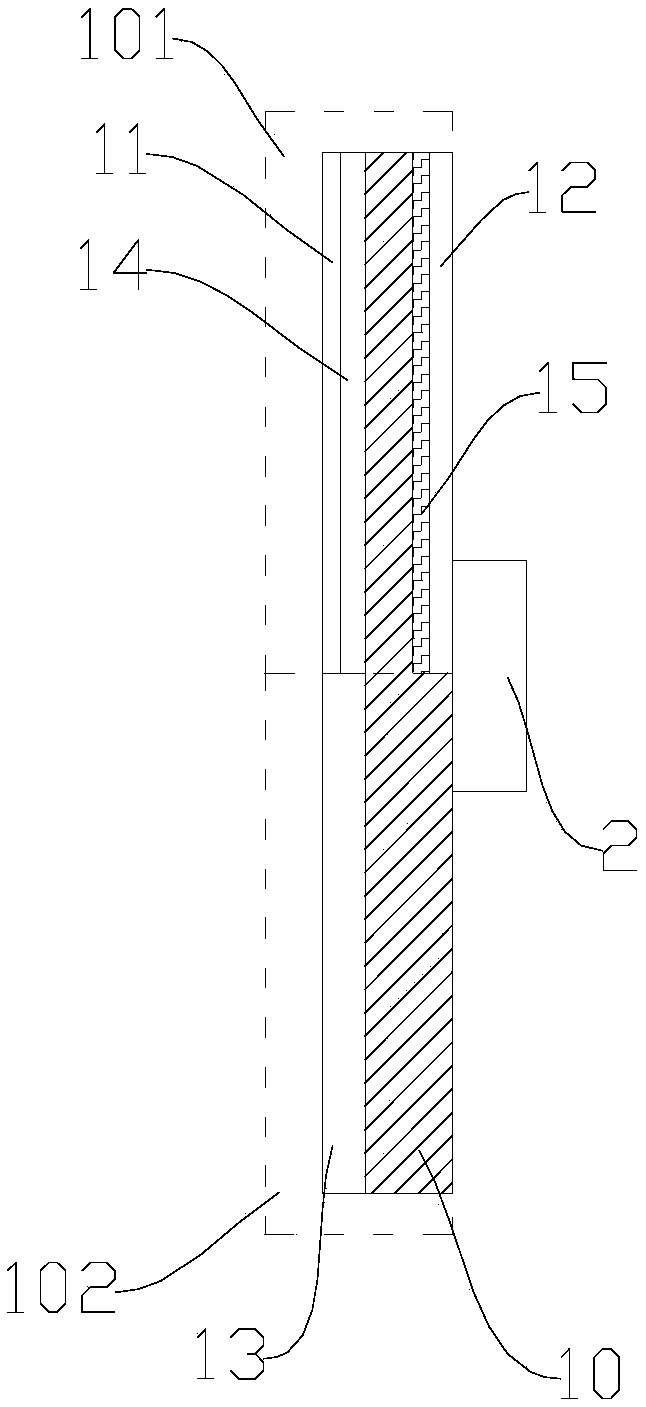

[0043] Specifically, such as figure 1 and figure 2 As shown, in the embodiment of the (reflective) wavelength conversion component 1 provided by the present invention, the substrate 10 is configured as a disk-shaped structure, and the fluorescent layer 11 is located on the first plate surface of the substrate 10 .

[0044] Further, the wavelength conversion component 1 has two fan-shaped wavelength conversion regions 101 and a fan-shaped transmission region 102, one of the wavelength conversion regions 101 has a fan-shaped yellow fluorescent layer 11, specifically, the yellow fluorescent layer 11 receives light Excited to generate yellow fluorescence; the other wavelength conversion region 101 has a fan-shaped green fluorescent layer 11, specifically, the green fluorescent layer 11 is excited by the laser to generate green fluorescence. Wherein, in other embodiments, in order to save material, the fluorescent layer 11 may be in a ring structure, wherein the center of the flu...

Embodiment 2

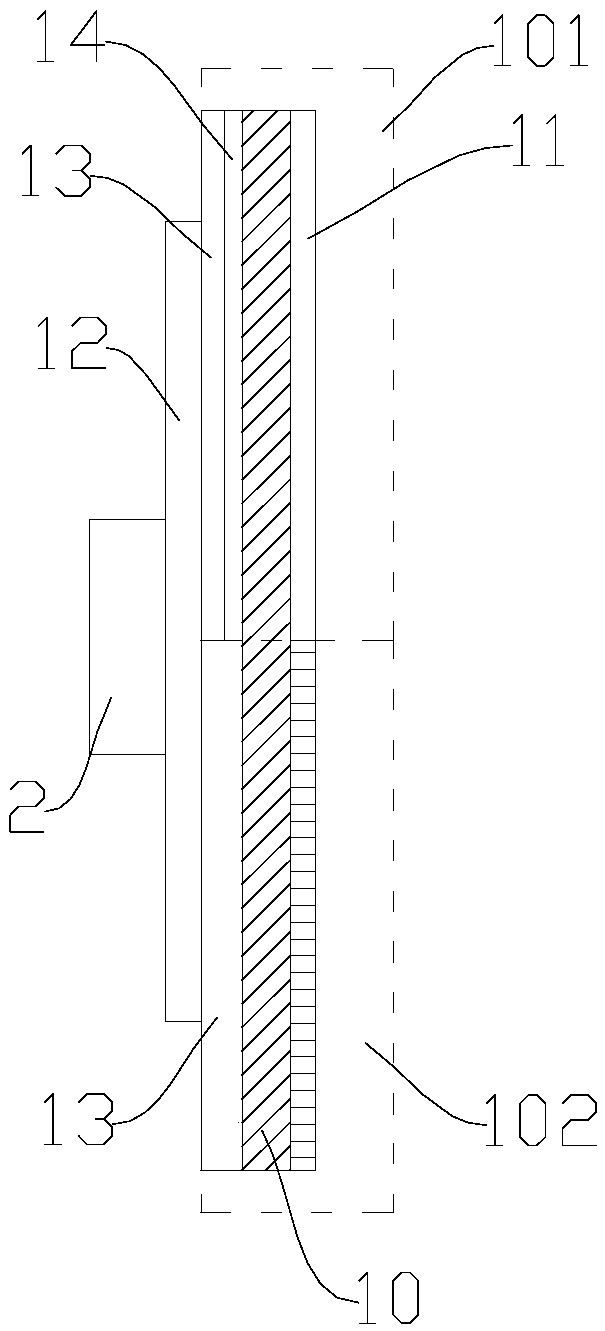

[0057] Specifically, such as figure 1 and image 3 As shown, in the embodiment of the (transmissive) wavelength conversion component 1 provided by the present invention, the substrate 10 is configured as a disk-shaped structure, and the fluorescent layer 11 is located on the first plate surface of the substrate 10 .

[0058] Further, the wavelength conversion component 1 has two fan-shaped wavelength conversion regions 101 and a fan-shaped transmission region 102, one of the wavelength conversion regions 101 has a fan-shaped yellow fluorescent layer 11, specifically, the yellow fluorescent layer 11 receives light Excited to generate yellow fluorescence; another wavelength conversion region 101 of the laser beam has a fan-shaped green fluorescent layer 11, specifically, the green fluorescent layer 11 is excited by the laser to generate green fluorescence. Wherein, in other embodiments, in order to save material, the fluorescent layer 11 may be in a ring structure, wherein the ...

Embodiment 3

[0070] Such as Figure 4 As shown, in this embodiment, the wavelength conversion component 1 is the (reflective) wavelength conversion component 1 of the first embodiment. Figure 4 The straight line in the optical path of the figure represents the laser beam, and the dotted line represents the fluorescent light beam (including yellow fluorescent light and green fluorescent light).

[0071] Specifically, the light beam emitted by the laser is blue light (spectral range of 420nm-470nm), which is adjusted to stable parallel light after the lens assembly 3a, and then passes through the dichroic mirror 4a to the lens assembly 3b, and the lens assembly 3b is used for The laser beam is focused and collimated, and the laser beam passes through the lens assembly 3 b and then shoots to the wavelength conversion component 1 .

[0072] When the laser beam hits the transmission area 102, the laser beam passes through the transmission area 102 and shoots to the lens assembly 3c, the lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com