Boiler flue gas denitrification control method based on self-adaptive fuzzy PID algorithm

An adaptive fuzzy, boiler flue gas technology, applied to controllers with specific characteristics, electric controllers, etc., can solve the problem that PID controller parameters are difficult to determine, overshoot large systems, and cannot solve the fundamental problems of dynamic performance and steady-state accuracy Contradictions and other problems, to achieve the effect of solving dynamic performance and steady-state accuracy, reducing overshoot frequency, and quickly stabilizing the state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments and effects of the present invention will be further described in detail below in conjunction with the accompanying drawings.

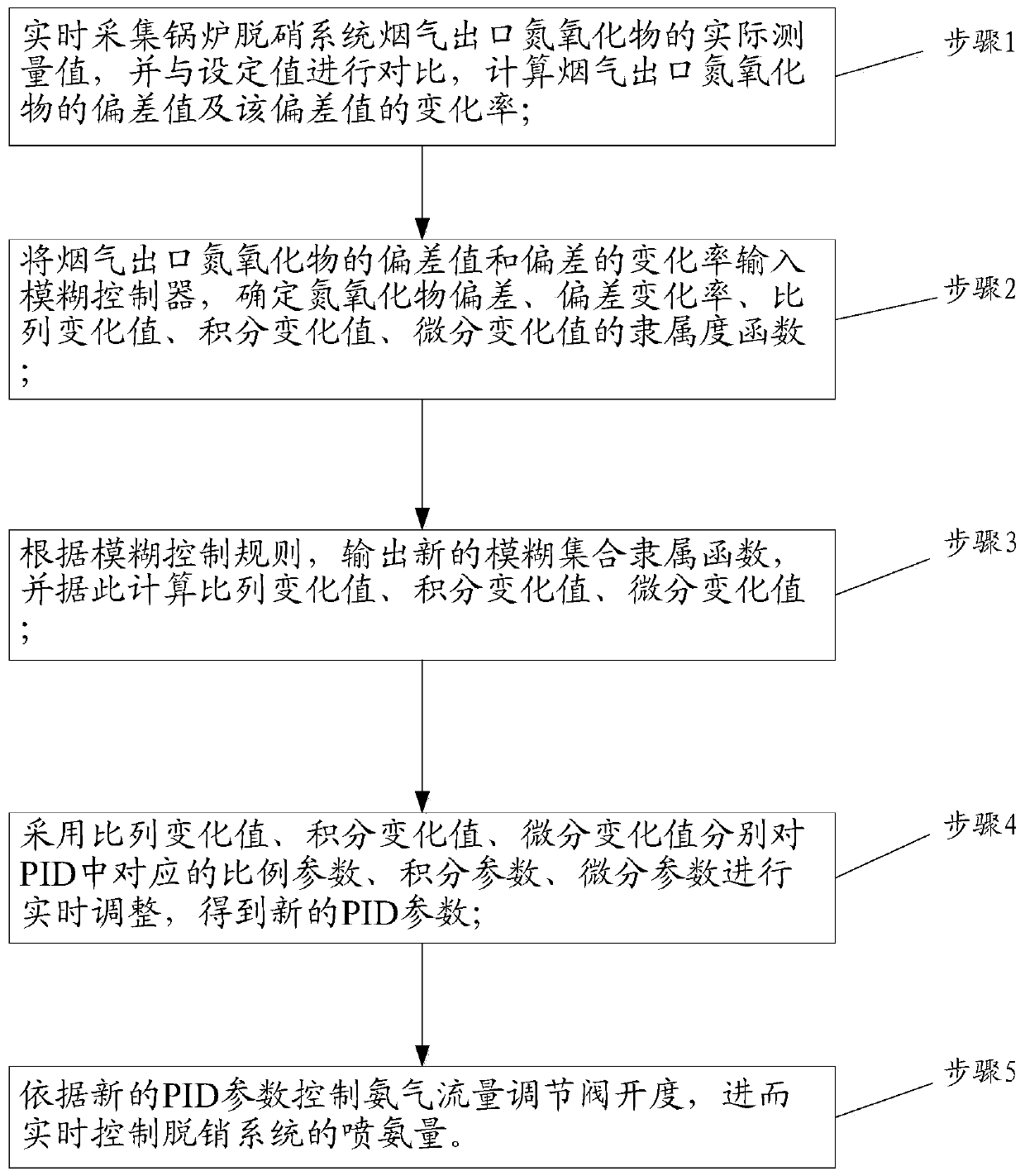

[0030] refer to figure 1 , the present invention is based on the boiler flue gas denitrification control method of adaptive fuzzy PID algorithm, and it is carried out according to the following steps:

[0031] Step 1, collect the actual measured value of nitrogen oxides at the flue gas outlet of the boiler denitrification system in real time, and compare it with the set value, and calculate the deviation value of the nitrogen oxides at the flue gas outlet and the rate of change of the deviation value;

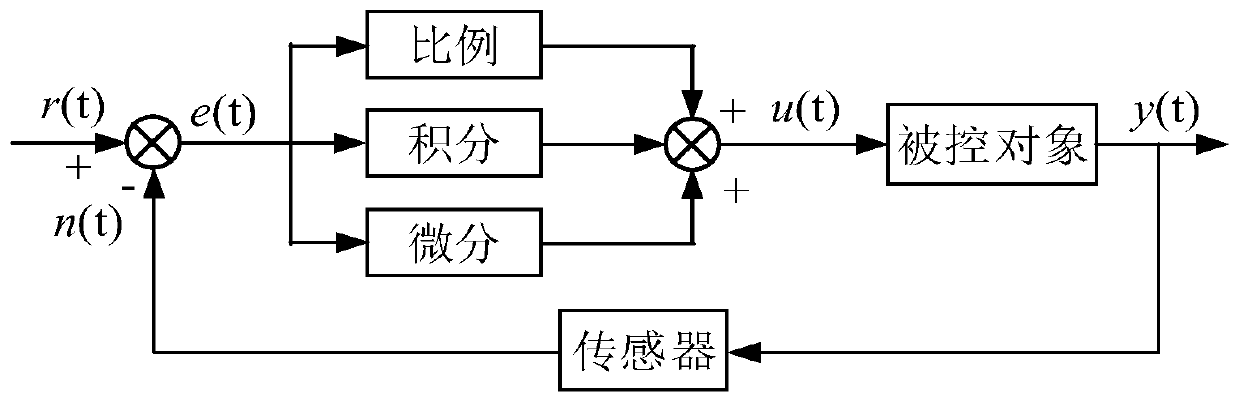

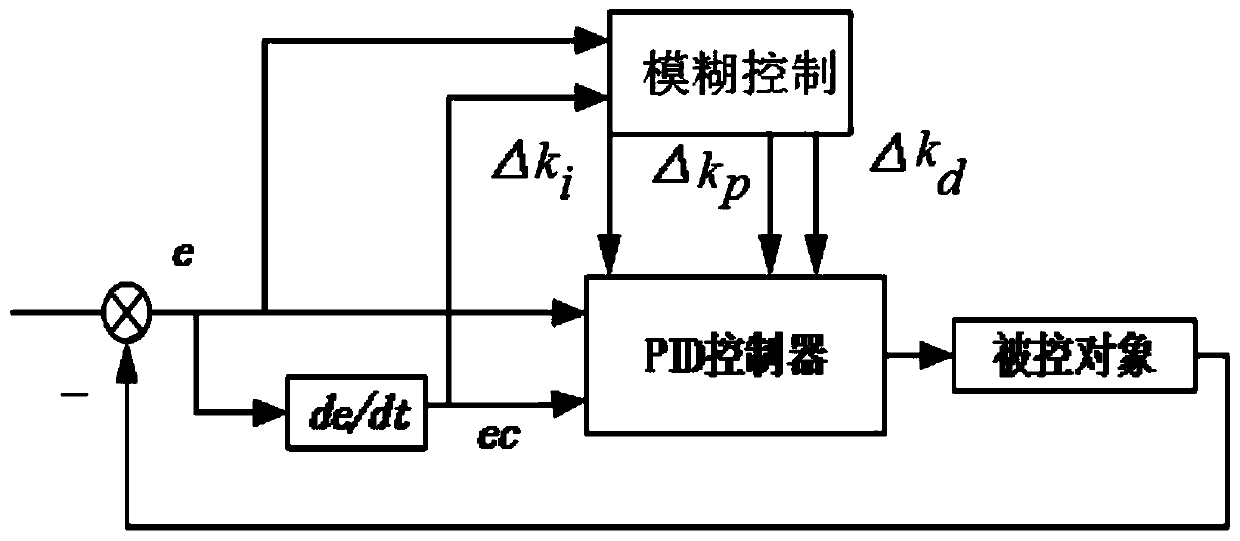

[0032] Specifically, refer to figure 2 , through the flue gas nitrogen oxide analyzer at the flue gas outlet of the boiler denitrification system, measure the concentration of nitrogen oxides in the flue gas at the outlet in real time, and compare it with the preset value to obtain the deviation value and its change rate; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com