Automatic ground control device and method for downhole quick orientation and collimation

An automatic control device and surface technology, applied in the automatic control system of drilling, directional drilling, drilling equipment, etc., can solve the problems of large axial friction, easy stall of the steering motor, low efficiency of wellbore purification, etc., and prolong the service life. , reduce the operating pressure and improve the effect of low wellbore purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

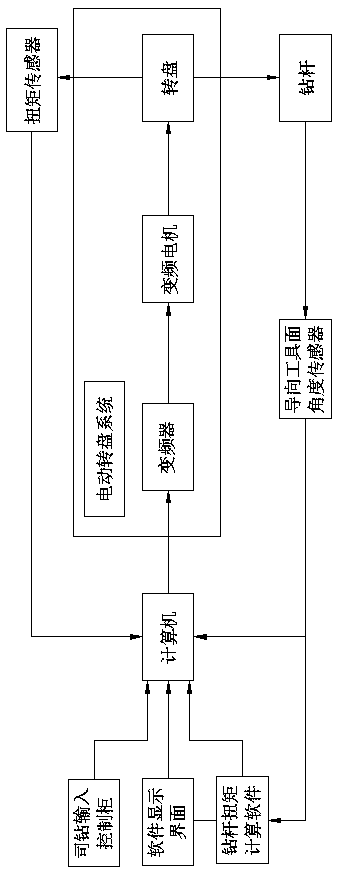

[0021] The ground automatic control method of the downhole rapid directional aiming comprises the following steps:

[0022] Firstly, the tool face angle indication signal of the downhole steering motor 17 fed back by the steering tool face angle sensor 9 of the ground automatic control device for rapid orientation and aiming downhole and the torque value of the rotary table 2 driving the drill pipe 4 measured by the torque sensor 3 are transmitted to the computer 6 in.

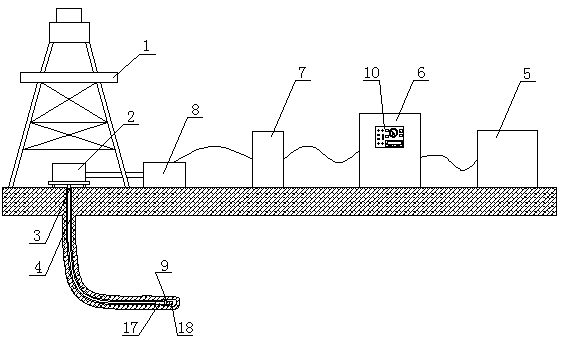

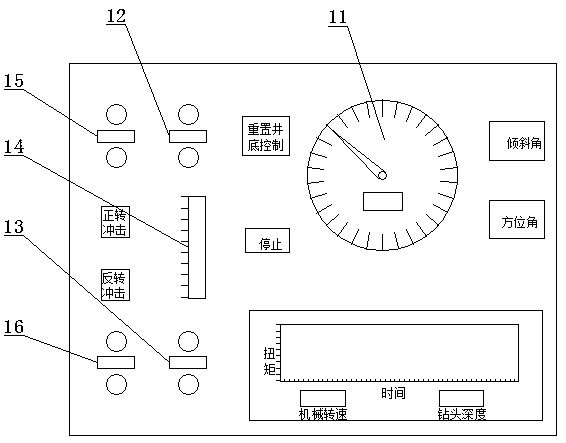

[0023] The ground automatic control device for fast directional and aiming downhole consists of a derrick 1, a turntable 2, a torque sensor 3, a drill pipe 4, a driller input control cabinet 5, a computer 6, a frequency converter 7, a frequency conversion motor 8 and a guide tool face angle sensor 9 , a turntable 2 is installed on the derrick 1, and a variable frequency motor 8, a frequency converter 7, a computer 6 and a driller input control cabinet 5 are installed on one side of the turntable 2 in sequence;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com