High-wear-resistance highway milling machine tool bit and manufacturing process thereof

A manufacturing process and a technology for a milling machine, which are applied to the high wear-resistant highway milling machine cutter head and its manufacturing process, can solve the problems of different wear progress, increased use costs, wasted time, etc., so as to improve service life and save time. cost, improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

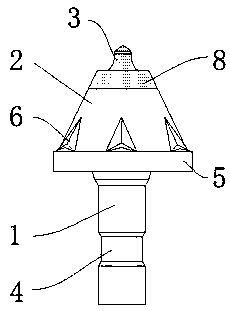

[0028] A high wear-resistant road milling machine cutter head, the overall cutter head is composed of a handle 1 and a blade body 2, the bottom surface of the handle 1 is provided with an arc-shaped installation groove 4, and the blade body 2 is installed on the top of the handle 1 , and a chassis 5 is provided between the blade body 2 and the handle 1, and the chassis 5 is located on the lower surface of the blade body 2, and several heat dissipation guide grooves 6 are provided at the bottom surface of the blade body 2, and the upper surface of the blade body 2 is fixedly connected with Install the ring 7, the outer surface of the installation ring 7 is welded with a wear-resistant ring 8, and the inwall of the installation ring 7 is welded with an alloy tip 3; its manufacturing process is as follows:

[0029] S1. Casting molding: pour molten iron into the molding mold, then cool it down to room temperature naturally, and demould to form the blank of the cutter head;

[0030...

Embodiment 2

[0036] A high wear-resistant road milling machine cutter head, the overall cutter head is composed of a handle 1 and a blade body 2, the bottom surface of the handle 1 is provided with an arc-shaped installation groove 4, and the blade body 2 is installed on the top of the handle 1 , and a chassis 5 is provided between the blade body 2 and the handle 1, and the chassis 5 is located on the lower surface of the blade body 2, and several heat dissipation guide grooves 6 are provided at the bottom surface of the blade body 2, and the upper surface of the blade body 2 is fixedly connected with Install the ring 7, the outer surface of the installation ring 7 is welded with a wear-resistant ring 8, and the inwall of the installation ring 7 is welded with an alloy tip 3; its manufacturing process is as follows:

[0037] S1. Casting molding: pour molten iron into the molding mold, then cool it down to room temperature naturally, and demould to form the blank of the cutter head;

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com