Device for continuously producing methyl nitrite gas and application of device

A methyl nitrite, gas technology, applied in the preparation of nitrite, chemical analysis using catalysis, organic chemistry, etc., can solve the problems of unstable methyl nitrite gas concentration, process or catalyst evaluation influence and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

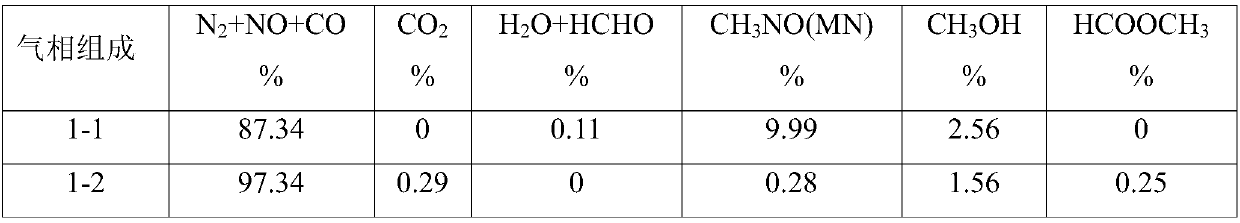

Embodiment 1

[0108] Use the above-mentioned device for continuous production of methyl nitrite gas and the catalytic reaction evaluation washing system with methyl nitrite as raw material in series, such as figure 1 shown. Before the experiment, 5 kg of raw material liquid was pre-prepared. In terms of mass percentage, the content of nitric acid in the liquid phase raw material was 8%, the content of methanol was 60%, and the content of water was 32%. Turn on N before reacting 2 Purging, the first mixing tank 3, methyl nitrite generation reactor 8, the first gas-liquid separator 9, drier 15, the second mixing tank 19, catalytic reactor 21, the second gas-liquid separator 22 and The entire pipeline is purged with nitrogen, and pressure-maintained and leak-tested to ensure the safety of the system. NO and N 2 Use the first flowmeter 1 such as mass flowmeter, the second flowmeter 2 such as mass flowmeter to set the flow rate as 8ml / min and 60ml / min respectively, enter the methyl nitrite ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com