Anti-crack cement mixture and preparation method thereof

A technology of mixture and cement, which is applied in the field of building material production, can solve problems such as cracks or damage on the ground, affect the overall strength of concrete blocks, and shorten life, so as to enhance hardness and frost resistance, improve brittleness and toughness, and improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

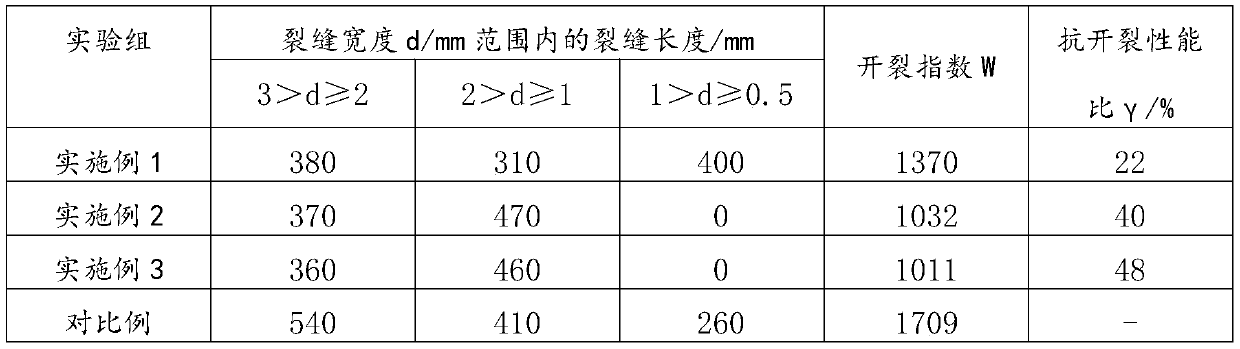

Examples

preparation example Construction

[0040] The present invention also provides a preparation method for the above-mentioned anti-cracking cement mixture, comprising the steps of:

[0041] Step S1, mixing cement, sand, oil shale ash and mineral powder to obtain a first mixture;

[0042] Step S2, grinding anhydrite to obtain 120-170 mesh anhydrite powder; mixing anhydrite powder, fibers and additives to obtain a second mixture;

[0043] Step S3, mixing the first mixture with the second mixture to obtain coarse cement;

[0044] Step S4, grinding the coarse cement material to 320-380 mesh to obtain an anti-cracking cement mixture;

[0045] There is no time sequence limitation between the step S1 and the step S2.

[0046]In the present invention, cement, sand, oil shale ash and slag are mixed in step S1 to obtain the first mixture. In this step S1, the mixing method is preferably stirring. The stirring speed is preferably 900-1200 rpm, more preferably 1000-1100 rpm. The stirring time is preferably 25-45 min, mor...

Embodiment 1

[0053] 46 parts of cement, 22 parts of sand, 19 parts of oil shale ash and 5 parts of mineral powder were mixed in a mixing tank at a stirring speed of 1000 rpm for 30 minutes to obtain the first mixed material. The anhydrite was ground by ball milling, the speed of the grinder was 500r / min, and the anhydrite was ground for 30min. After grinding, the anhydrite powder was sieved to obtain 120-mesh anhydrite powder. Mix 4 parts of anhydrite powder, 0.8 part of fiber and 0.5 part of admixture in a mixing tank at a stirring speed of 360 rpm for 18 minutes to obtain a second mixture. The first mixture and the second mixture are mixed to obtain coarse cement material. The cement coarse material is transported to a grinder by a conveyor belt for grinding at a rotational speed of 16 rpm for 40 min to 320 mesh to obtain a crack-resistant cement mixture.

Embodiment 2

[0055] 78 parts of cement, 30 parts of sand, 21 parts of oil shale ash and 8 parts of mineral powder were mixed in a mixing tank at a stirring speed of 900 rpm for 25 minutes to obtain the first mixed material. The anhydrite was ground by means of ball milling, the rotational speed of the grinder was 450r / min, and the anhydrite was ground for 20min. After grinding, the anhydrite powder was sieved to obtain 130-mesh anhydrite powder. 7 parts of anhydrite powder, 3.2 parts of fiber and 1.2 parts of admixture were mixed in a mixing tank at a stirring speed of 420 rpm for 26 minutes to obtain a second mixed material. The first mixture and the second mixture are mixed to obtain coarse cement material. The cement coarse material is transported to a grinder by a conveyer belt for grinding at a rotational speed of 20 rpm for 50 min to 340 mesh to obtain a crack-resistant cement mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com