an α-fe 2 o 3 /bi 2 the w 6 Shell composite photocatalyst and preparation method thereof

A -fe2o3, composite light technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low photocatalyst efficiency and high preparation cost, and achieve Improve photocatalytic performance, low cost, and improve the effect of photocatalytic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0043] Preparation of bismuth tungstate powder:

[0044] S1) Prepare 0.06-0.08mol / L sodium tungstate solution and 0.12-0.16mol / L bismuth salt solution respectively, and add the sodium tungstate solution dropwise into the bismuth salt solution to obtain a pre-solution;

[0045] S2) Add sodium lauryl sulfate to the pre-solution obtained in step S1), add 12-15 g of sodium lauryl sulfate per liter of pre-solution, mix well and let stand for 3-4 hours, then place it at 160-185 After drying at ℃ for 20-28 hours, filter out the precipitate, wash the precipitate with water until it becomes neutral, and then dry it to obtain bismuth tungstate powder.

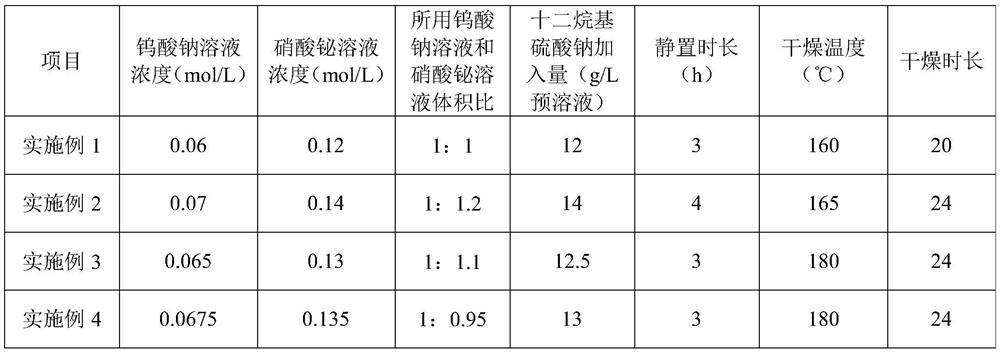

[0046] The above specific preparation parameters are shown in Table 1 below.

[0047] The concrete preparation parameter of table 1 bismuth tungstate powder

[0048]

[0049]

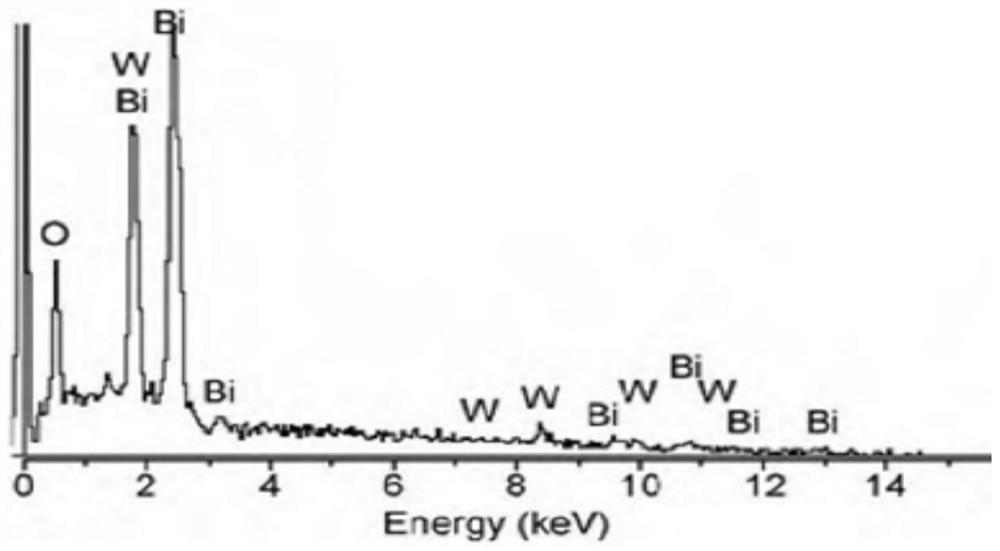

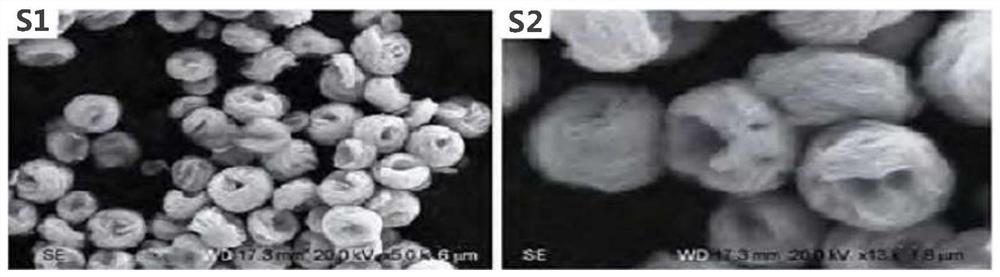

[0050] The bismuth tungstate powder prepared in Examples 1 to 6 is detected and characterized, and the EDS diagram of the bismuth tungstate powder prepare...

Embodiment 7~12

[0053] Utilize the bismuth tungstate powder that embodiment 1~6 makes to prepare α-Fe 2 o 3 / Bi 2 WO 6 / shell composite photocatalyst, its specific steps include:

[0054] 1) Grinding the shells and sieving the shell powder with a particle size of 5-15 μm, as a carrier, dispersing the carrier in a molten organic dispersant;

[0055] 2) adding bismuth tungstate powder and iron source to the molten organic dispersant in step 1), mixing them evenly, and then water-cooling and solidifying to obtain a precursor;

[0056] 3) Burn the precursor at 450-550°C for 1-3 hours to obtain α-Fe 2 o 3 / Bi 2 WO 6 / shell composite photocatalyst.

[0057] The specific parameters in the preparation process are shown in Table 2 below.

[0058] Table 2 α-Fe 2 o 3 / Bi 2 WO 6 / Specific parameters for the preparation of shell composite photocatalysts

[0059]

[0060] For the prepared α-Fe 2 o 3 / Bi 2 WO 6 / shell composite photocatalysts were detected in which α-Fe 2 o 3 and Bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com