A kind of FRP grating production and finishing processing machine

A grid plate, glass fiber reinforced plastic technology, applied in metal processing and other directions, can solve the problems of inability to meet industrial production, labor intensity of workers, low efficiency, etc., to achieve the effect of improving economic practicability, high efficiency, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

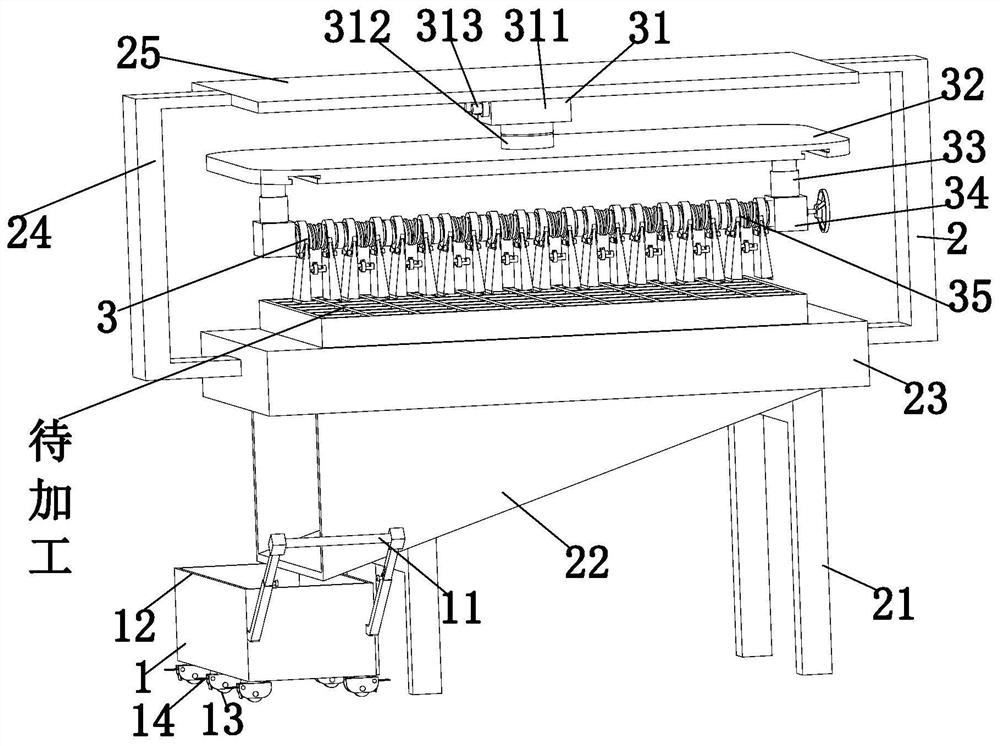

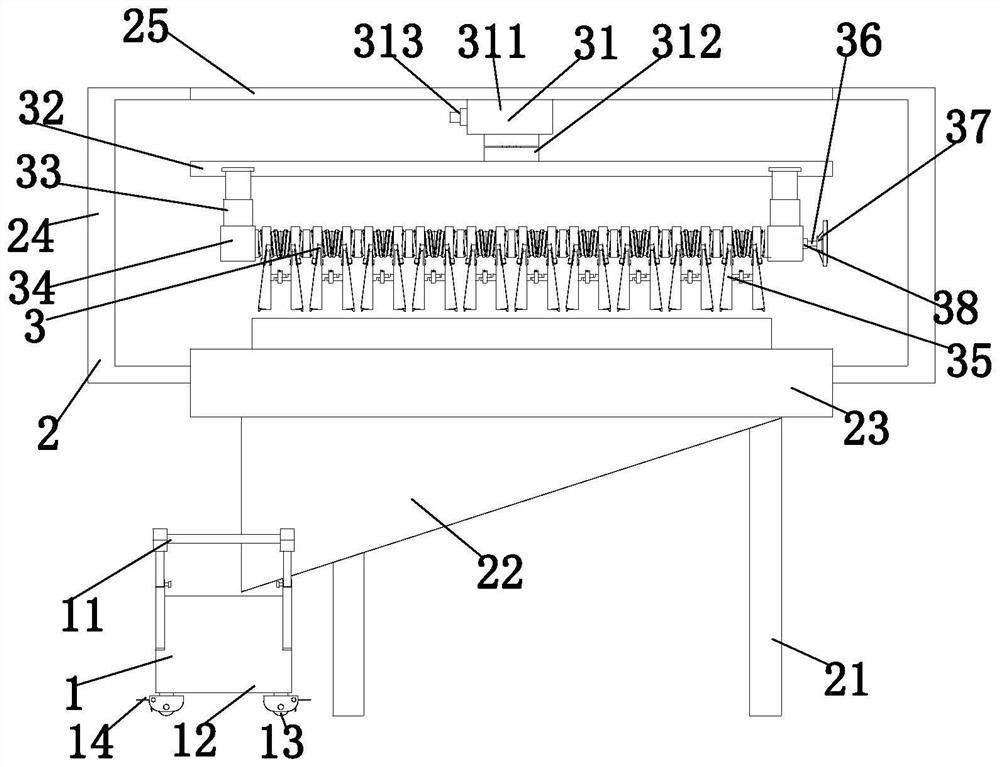

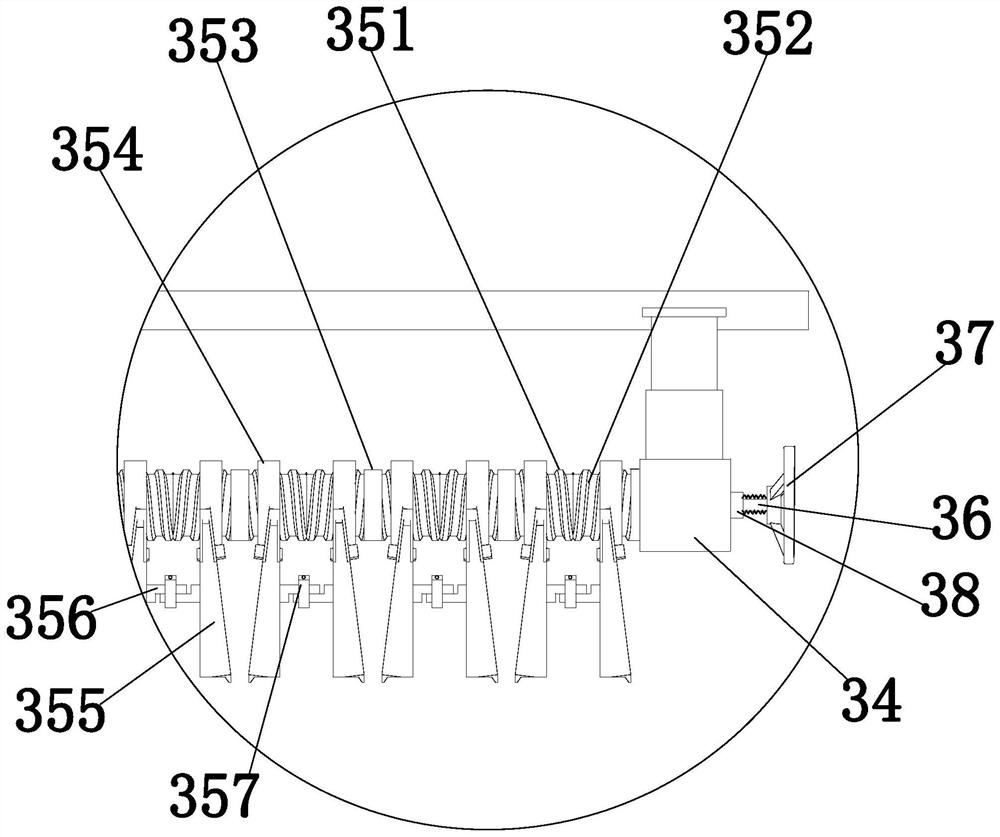

[0026] Such as Figure 1 to Figure 3 As shown, a finishing processing machine for the manufacture of FRP gratings, including a collection mechanism 1, a support mechanism 2 and an actuator 3, the actuator 3 is installed above the middle of the support mechanism 2, and the collection mechanism 1 is set under the support mechanism 2, and the actuator 3 is located above the material collection mechanism 1; where:

[0027] The collection mechanism 1 includes an adjustment handle 11, a collection frame 12, a pulley 13 and a brake pad 14; the adjustment handle 11 is installed on the collection frame 12, and the inner wall of the adjustment handle 11 Height adjustment holes are evenly arranged, and the inner wall of the adjustment handle 11 is evenly prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com