Ultrasonic welding process control and quality monitoring device and method

An ultrasonic welding and process control technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of inability to adapt to the needs of automated production lines, difficulty in adapting to ultrasonic welding, lack of quality monitoring system, etc., to improve welding quality , to achieve the effect of quality improvement and upgrading, and control of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of the invention and supplement the content of the invention, but not to limit the application of the present invention.

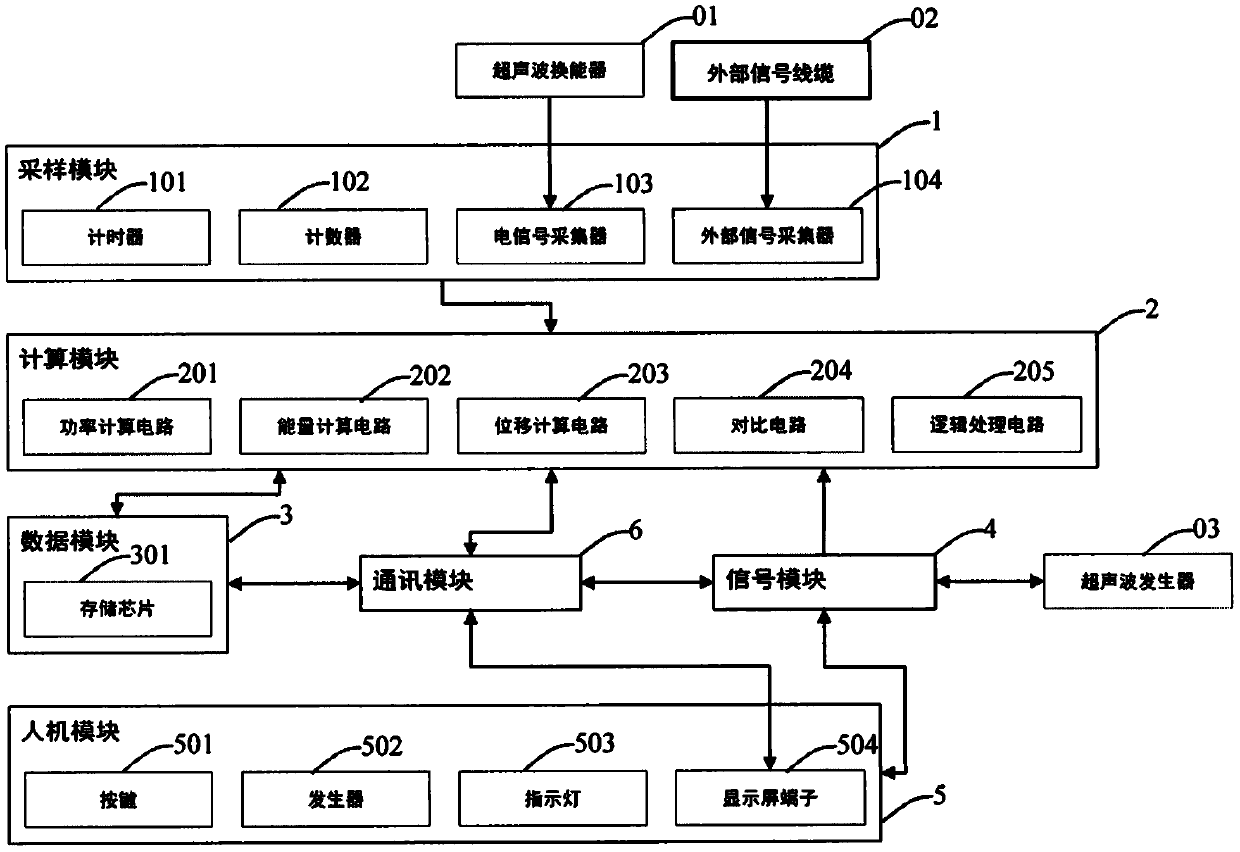

[0051] figure 1 It is a structural block diagram of the present invention, and describes the structure and application mode of the present invention. Among them, 1 is the sampling module, 2 is the calculation module, 3 is the data module, 4 is the signal module, 5 is the man-machine module, 6 is the communication module, and the corresponding circuits inside and outside the module. The connections between the modules are shown in the figure. Among them, the sampling module 1 is connected with the external ultrasonic transducer 01 and the external signal cable 02 through physical terminals; the signal module 4 is connected with the human-machine module and the external ultrasonic generator 03 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com