A kind of preparation method of doped graphitic carbon nitride material

A technology of carbon nitride and graphite, applied in the field of preparation of graphitic carbon nitride, can solve the problems of limiting the performance of graphite carbon nitride materials, no photocatalytic activity, low photocatalytic activity, etc., and is convenient for large-scale industrialization. The effect of producing, improving photocatalytic activity, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] After grinding 10g of urea evenly, put it into a ceramic crucible; after grinding 10mg of copper acetylacetonate evenly, put it into a quartz boat; place the quartz boat with copper acetylacetonate in a ceramic crucible; put the ceramic crucible into In the muffle furnace, the reaction pressure is 1MPa, the heating rate is 5°C / min to 550°C, and then the temperature is kept for 4 hours. After the reaction system is cooled to room temperature with the furnace, the light yellow sample is taken out.

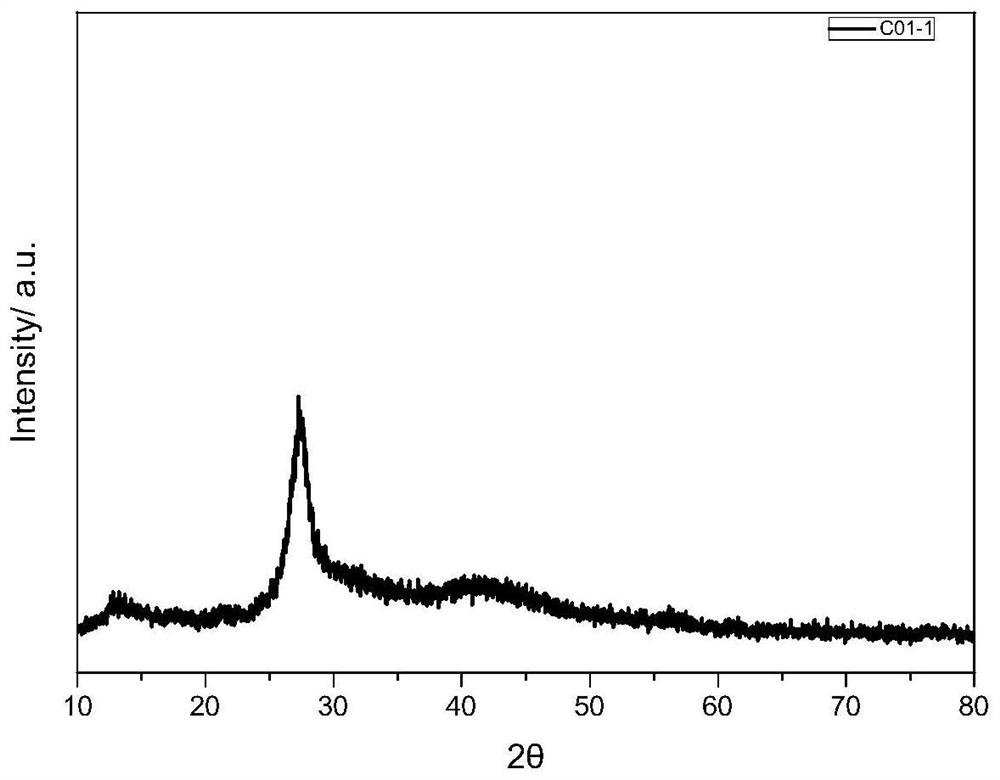

[0033] The structure of the obtained light yellow sample was characterized by X-ray diffraction pattern.

[0034] figure 1 is the X-ray diffraction pattern of the resulting product, which can prove that the modified sample still has a graphite-like layered carbon nitride, that is, graphite-like carbon nitride.

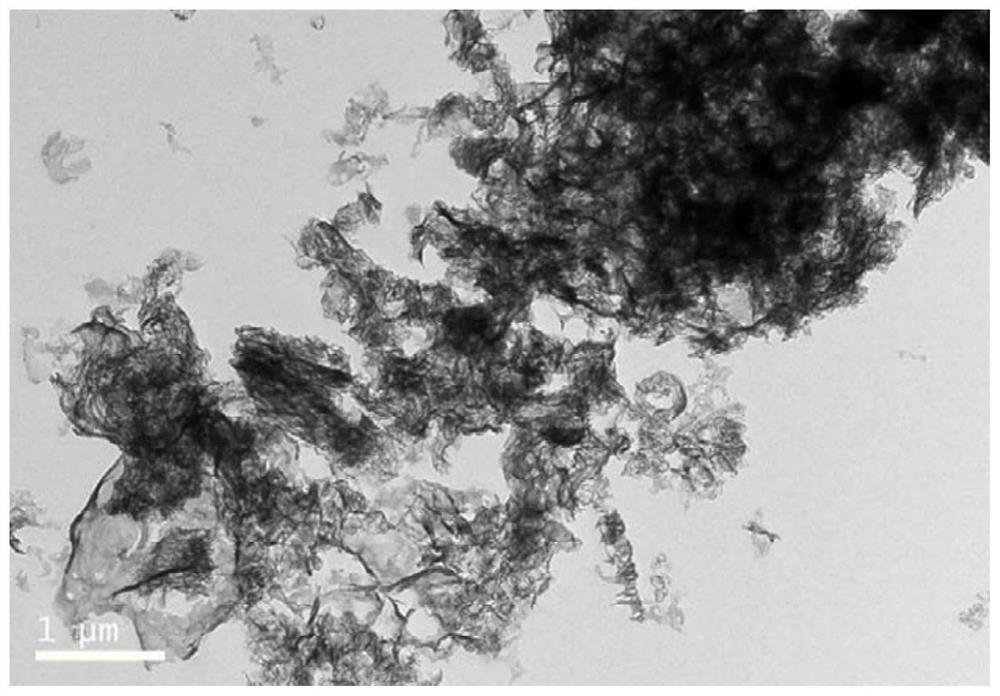

[0035] figure 2 It is a transmission electron microscope picture of the obtained product. It can be seen from the figure that the modified carbon nitride has a lame...

Embodiment 2

[0063] This example is a modification example of Example 1, which only involves changing the calcination temperature and holding time: specifically, in the steps of Example 1, the ceramic crucible is placed in the muffle furnace, and the temperature is raised to 450 °C at a heating rate of 5 °C / min After ℃, start to keep warm, and keep warm for 6 hours. Other steps and test conditions remain unchanged, and the measured hydrogen production rate is 320umol / h.

Embodiment 3

[0065] This embodiment is a modification of embodiment 1, which only involves changing the calcination temperature and holding time: specifically, in the steps of embodiment 1, the ceramic crucible is placed in the muffle furnace, and the temperature is raised to 550 °C at a heating rate of 5 °C / min. After ℃, start to keep warm and keep warm for 2 hours. Other steps and test conditions remain unchanged, and the measured hydrogen production rate is 270umol / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com