Chemical plant safety supervision, training and assessment system and method with post instructions

A technology for chemical plants and posts, which is applied in the field of chemical plant safety supervision, training and assessment systems with post instructions, and can solve the problems of lack of pre-plan implementation in chemical plants and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

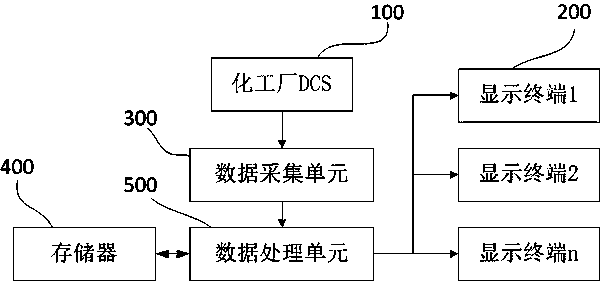

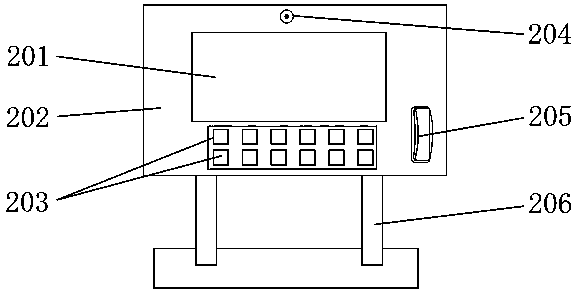

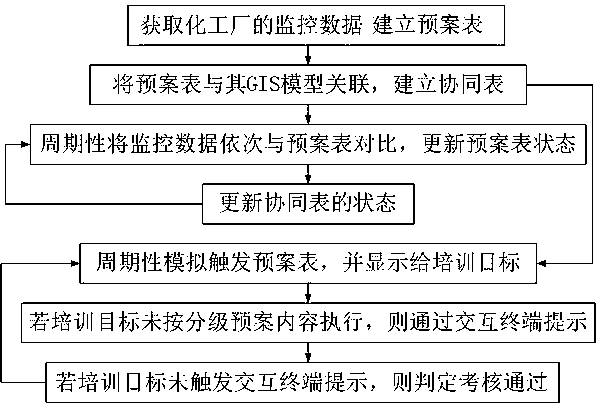

[0031] A chemical plant safety supervision, training and assessment system with job instructions, such as figure 1 As shown, it includes a data acquisition unit 300, a data processing unit 500, a memory 400, and several interactive terminals 200. The data acquisition unit 300 communicates with the chemical plant DCS100 and reads the monitoring data of the chemical plant, such as figure 2 As shown, the interactive terminal 200 includes a rack 206, a display screen 201, a display screen 201 driver, a camera 204, a voice communication device 205, an indicator, a temperature sensor, a wind speed sensor, a wind direction sensor, a hazardous gas detector and an alarm, and a rack 206 is installed near the workplace of the employees of the chemical plant. The display screen 201, camera 204, voice communication device 205, and alarm are all fixedly installed on the rack 206. The driver of the display screen 201 communicates with the data processing unit 500, and the data processing unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com