A method and device for feeding gas into submerged arc furnace to reduce energy consumption

A submerged arc furnace and gas technology, applied in the field of metallurgy, can solve the problem of low utilization rate of submerged arc furnace flue gas, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

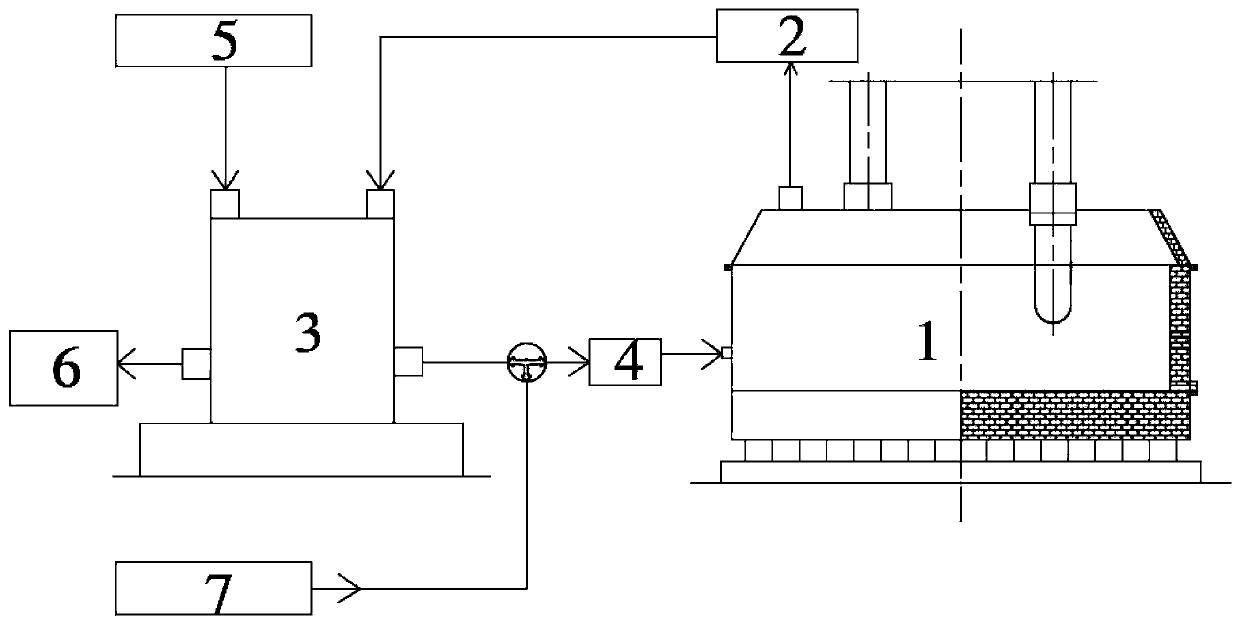

[0032] Further explanation in conjunction with accompanying drawings:

[0033] Such as figure 1 As shown, the main process flow is that the flue gas from the submerged arc furnace 1 first enters the flue gas treatment system 2 for dust removal. The flue gas treatment system 2 is mainly a bag filter, and then the flue gas from the submerged arc furnace after dust removal enters the In the gas buffer device 3, the external air is passed into the gas buffer device 3 through the gas supply device 5, and the submerged arc furnace flue gas in the gas buffer device 3 is mixed with the external gas and then enters the submerged arc furnace through the submerged arc furnace air inlet device 4 Reaction in the submerged arc furnace, as gas supplement, at the same time, the external gas directly enters the submerged arc furnace through the gas supply device 7 and the submerged arc furnace air intake device 4 for reaction.

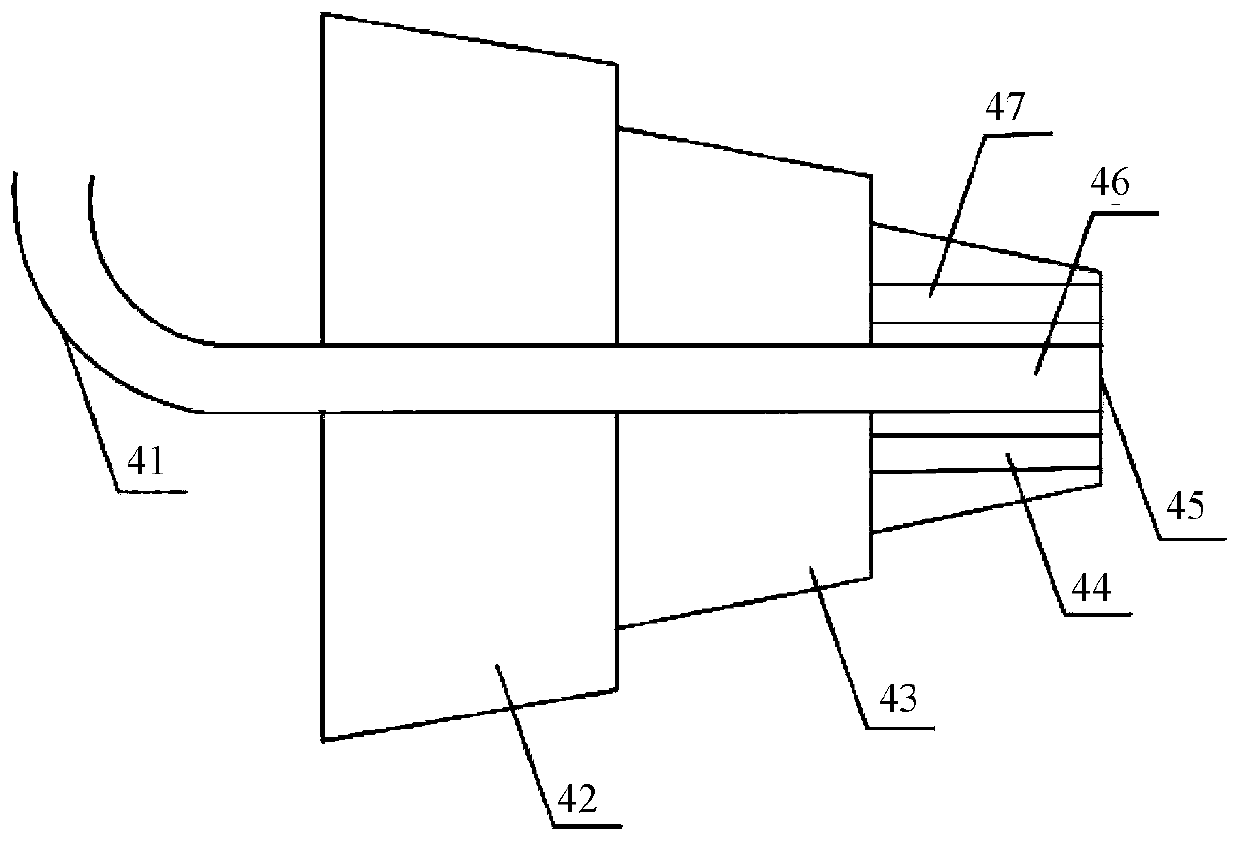

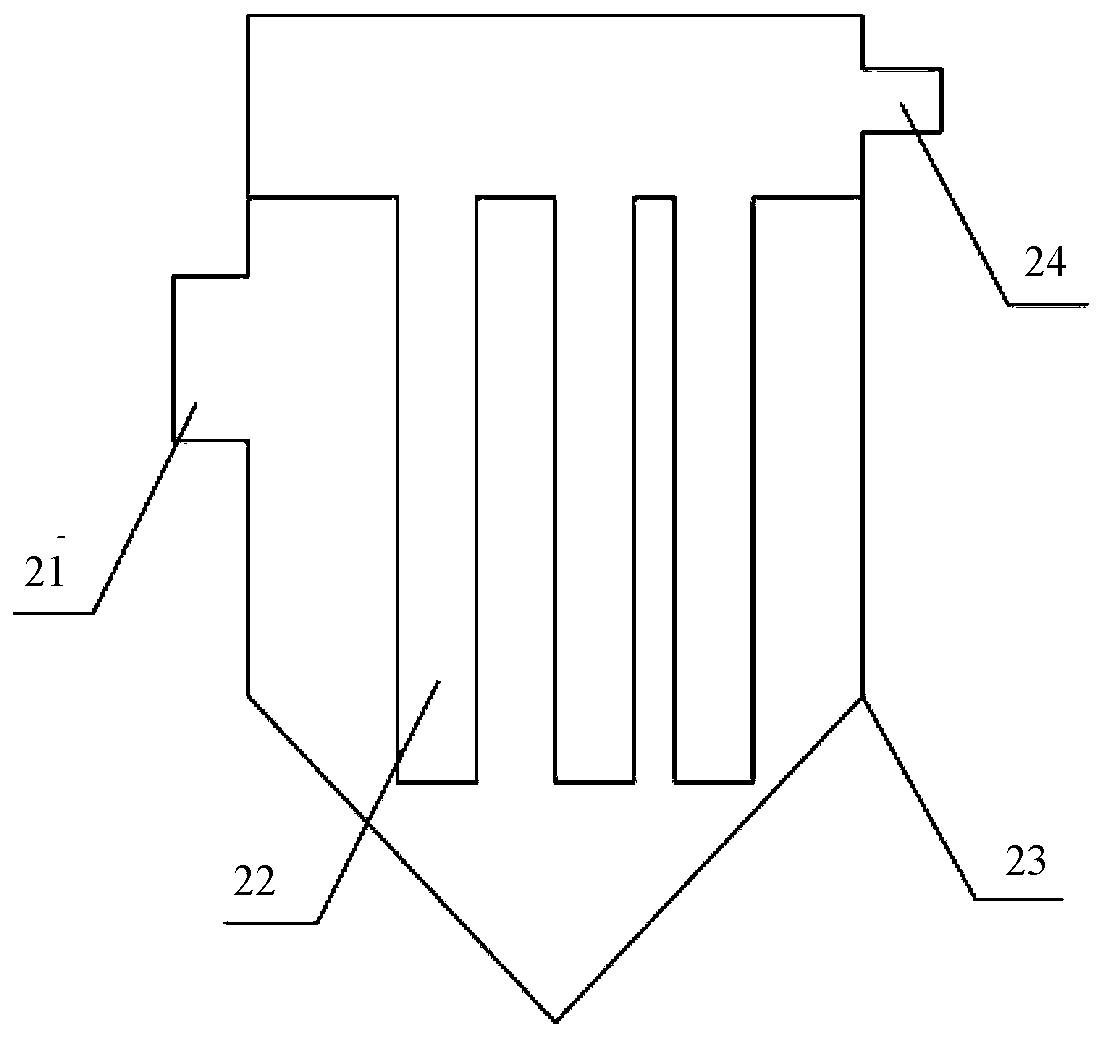

[0034] Such as figure 2 As shown, the air inlet device of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com