Magnesium phosphate cement base fiber composite material and preparation method thereof

A technology of fiber composite materials and magnesium phosphate cement, which is applied in the field of construction composite materials, can solve the problems of inability to construct existing structures, long maintenance periods, and large dry shrinkage, and achieve excellent volume stability and good work performance , the effect of high early intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

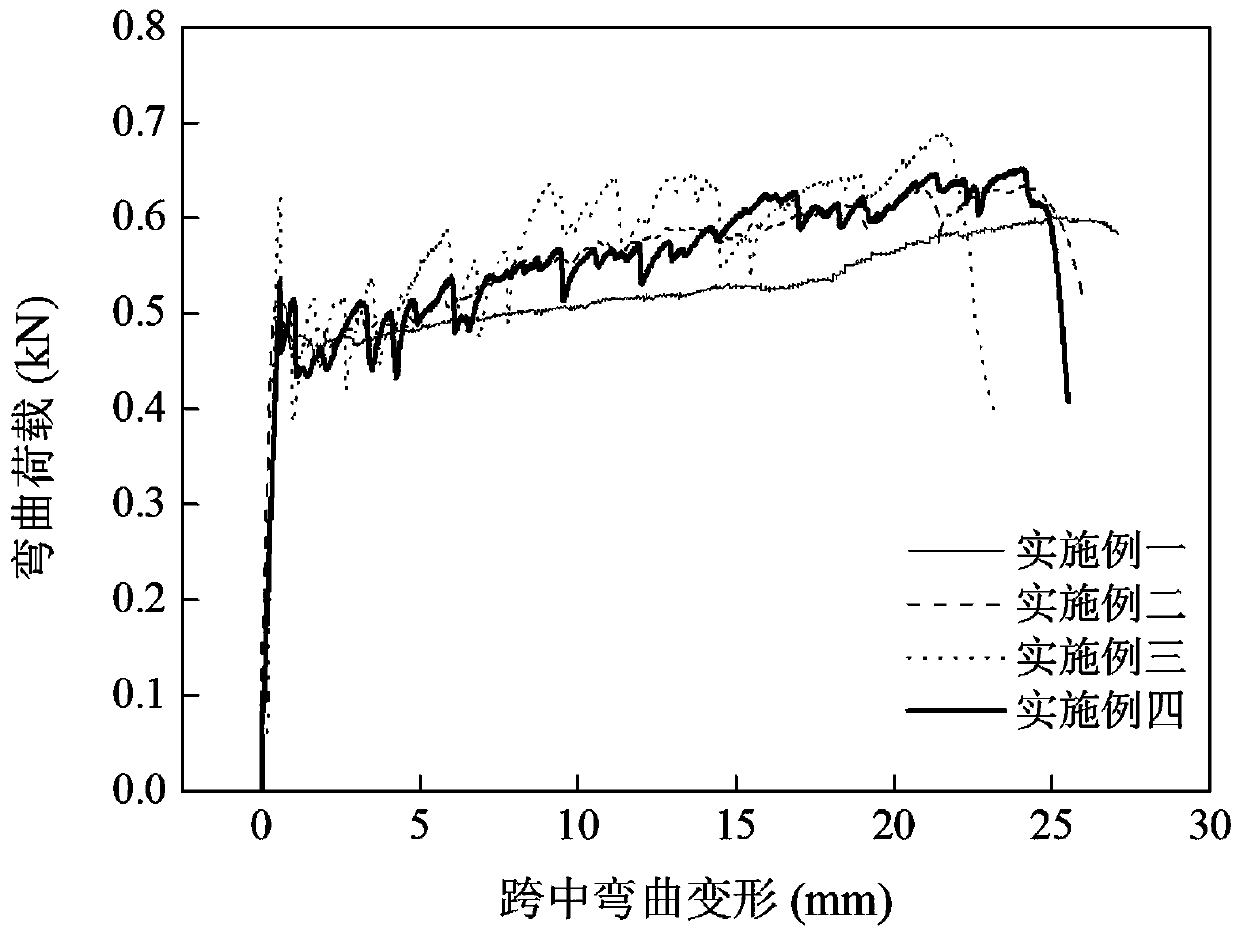

Embodiment 1

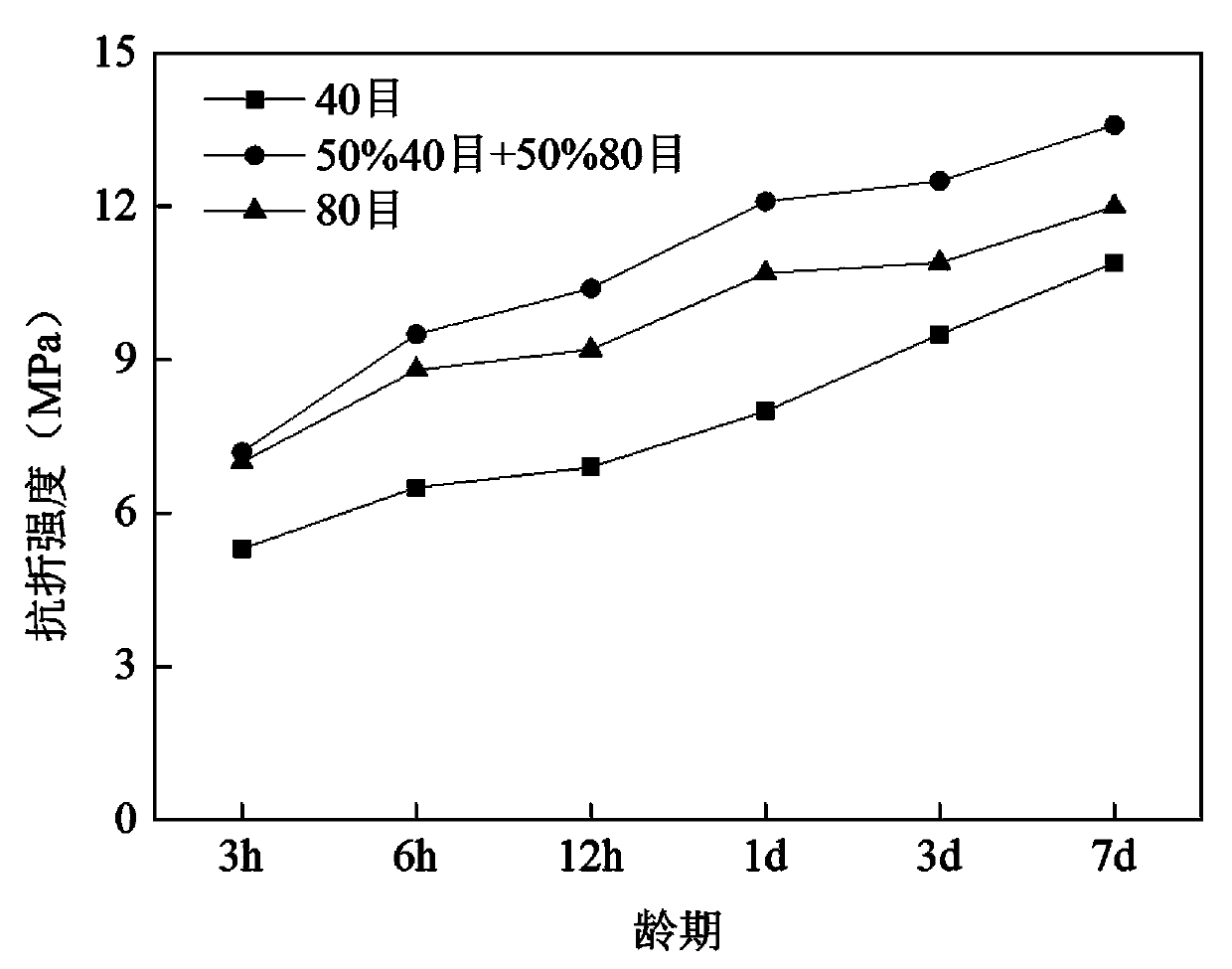

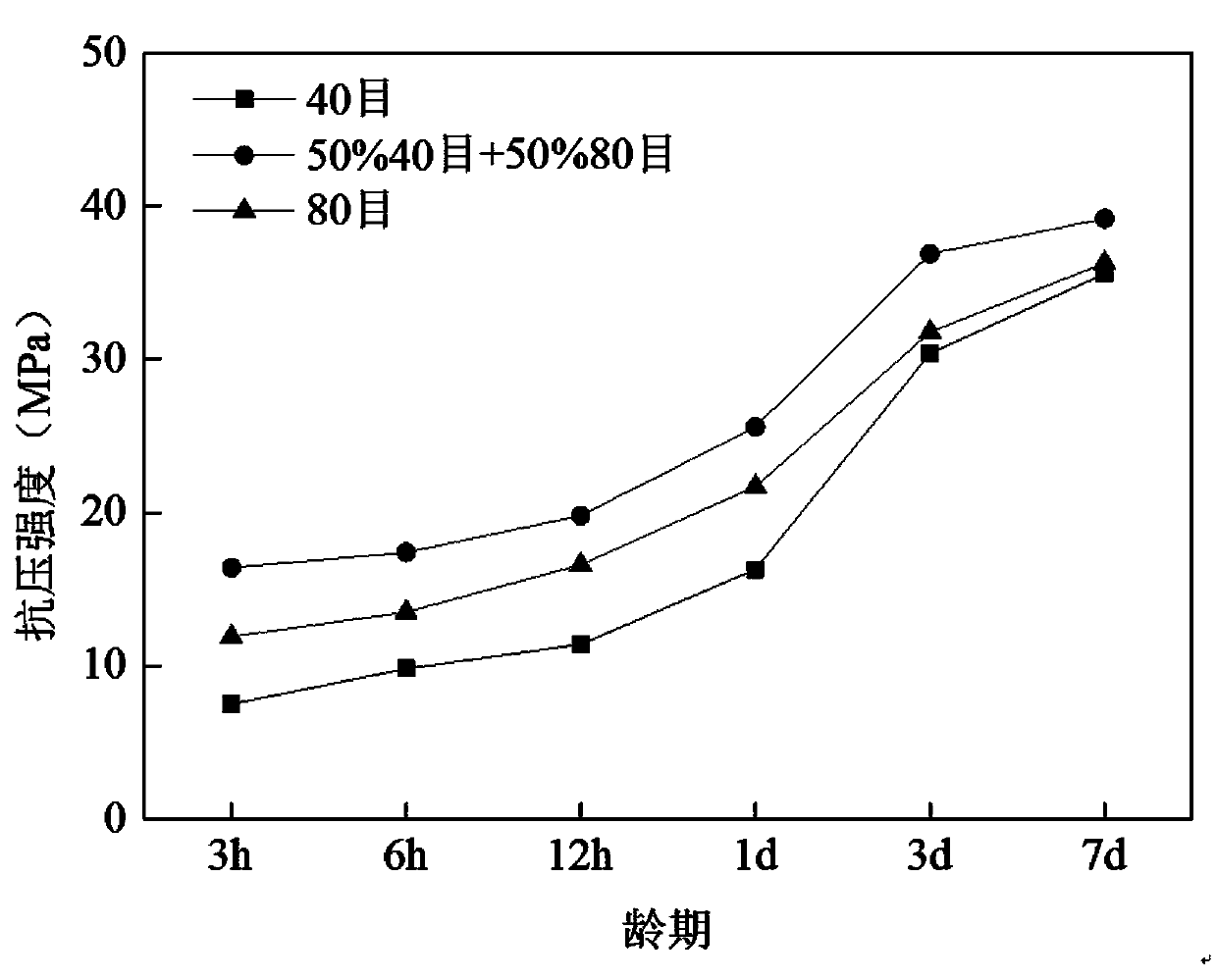

[0035] The magnesium phosphate cement-based fiber composite material consists of 688.2kg of dead-burned magnesia, 585.0kg of potassium dihydrogen phosphate, 41.3kg of borax, 318.3kg of fly ash, 20.8kg of polyvinyl alcohol fiber, 248.3kg of water and 318.3 kg of quartz sand, borax, and potassium dihydrogen phosphate are composed of potassium dihydrogen phosphate particles with a particle size of 40 mesh and potassium dihydrogen phosphate particles with a particle size of 80 mesh, and potassium dihydrogen phosphate particles with a particle size of 40 mesh and potassium dihydrogen phosphate The mass ratio of hydrogen potassium particles is 1:1, and the specific surface area of dead-burned magnesium oxide is 315.7m 2 / kg.

[0036] The selection of each mixture in the composite material is as follows:

[0037] The specific surface area of dead-burned magnesia is 315.7m 2 / kg, the particle size distribution is shown in Table 1, and the composition is shown in Table 2.

[003...

Embodiment 2

[0062] Different from Example 1, the magnesium phosphate cement-based fiber composite material is composed of 686.9kg of dead-burned magnesium oxide, 583.9kg of potassium dihydrogen phosphate, 41.2kg of borax, 317.7kg of fly ash, and 24.4kg of polyethylene Alcohol fiber, 247.8kg of water and 317.7kg of quartz sand.

Embodiment 3

[0064] Different from Example 1, the magnesium phosphate cement-based fiber composite material consists of 823.4kg of dead-burned magnesium oxide, 699.8kg of potassium dihydrogen phosphate, 49.4kg of borax, 380.8kg of fly ash, and 20.8kg of polyvinyl alcohol Fiber, 247.7kg of water and 0kg of quartz sand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap