A kind of light gypsum spray mortar

A technology for spraying mortar and gypsum, which is applied in the field of building materials, can solve problems such as cost increase, and achieve the effects of facilitating spraying construction, improving workability, and ensuring spraying strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

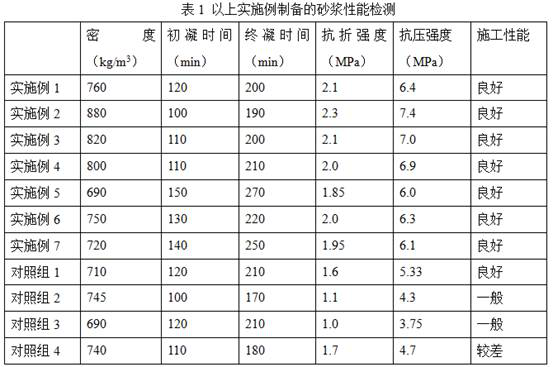

Examples

Embodiment 1

[0035] A lightweight gypsum spraying mortar, comprising the following components: 65kg of desulfurized gypsum, 6kg of calcium dialuminate, 1.15kg of CSH gel seed crystals, 3kg of ordinary Portland cement, 14kg of modified slag ash, 10kg of heavy calcium powder, 0.5kg of nano titanium dioxide, 0.055kg of cellulose ether with a viscosity of 100,000, 0.1kg of starch ether and 0.01kg of sodium α-olefin sulfonate. Wherein the preparation method of modified slag ash is as follows:

[0036] (1) The slag ash of 50-100 mesh accounts for 20 parts by weight, 100-140 mesh accounts for 40 parts by weight, and 140-300 mesh accounts for 40 parts by weight.

[0037] (2) Pour the slag ash into the hydrofluoric acid solution with an excess concentration of 3%, and soak for 48 hours.

[0038] (3) Mix zeolite powder with a mesh number of 800-1000 mesh and quartz glass powder with a mesh number of 1000-1500 and pour them into (1) evenly, and stir slowly. Where m (zeolite powder): m (quartz glass...

Embodiment 2

[0042] A lightweight gypsum spraying mortar, including the following components: 75kg of desulfurized gypsum, 2.5kg of calcium dialuminate, 0.965kg of CSH gel seed crystals, 1kg of ordinary Portland cement, 14kg of modified slag ash, and 6kg of heavy calcium powder , 0.37kg of nano-titanium dioxide, 0.06kg of 100,000-viscosity cellulose ether, 0.1kg of starch ether and 0.005kg of sodium α-olefin sulfonate.

[0043] Wherein the preparation method of modified slag ash is as follows:

[0044](1) The slag ash of 50-100 mesh accounts for 25 parts by weight, 100-140 mesh accounts for 45 parts by weight, and 140-300 mesh accounts for 30 parts by weight.

[0045] (2) Pour the slag ash into the hydrofluoric acid solution with an excess concentration of 4%, and soak for 48 hours.

[0046] (3) Mix zeolite powder with a mesh number of 800-1000 mesh and quartz glass powder with a mesh number of 1000-1500 and pour them into (1) evenly, and stir slowly. Where m (zeolite powder): m (quartz ...

Embodiment 3

[0050] A lightweight gypsum spraying mortar, including the following components: 70kg of desulfurized gypsum, 5kg of calcium dialuminate, 0.765kg of CSH gel seed crystals, 2.5kg of ordinary Portland cement, 12kg of modified slag ash, and 9.3 kg of heavy calcium powder kg, 0.27kg of nano-titanium dioxide, 0.06kg of 100,000-viscosity cellulose ether, 0.09kg of starch ether and 0.008kg of sodium α-olefin sulfonate.

[0051] Wherein the preparation method of modified slag ash is as follows:

[0052] (1) The slag ash of 50-100 mesh accounts for 20 parts by weight, 100-140 mesh accounts for 40 parts by weight, and 140-300 mesh accounts for 40 parts by weight.

[0053] (2) Pour the slag ash into the hydrofluoric acid solution with an excess concentration of 3%, and soak for 48 hours.

[0054] (3) Mix zeolite powder with a mesh number of 800-1000 mesh and quartz glass powder with a mesh number of 1000-1500 and pour them into (1) evenly, and stir slowly. Where m (zeolite powder): m (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com