Porous carbon material and method for preparing porous carbon material using microwave hot zone effect

A porous carbon material and carbon material technology, applied in the field of porous materials, can solve the problems of excessive hydroxide recovery, strong corrosion, high raw material cost, etc., to promote rapid contact reaction, reduce consumption, and reduce the cost and difficulty of recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

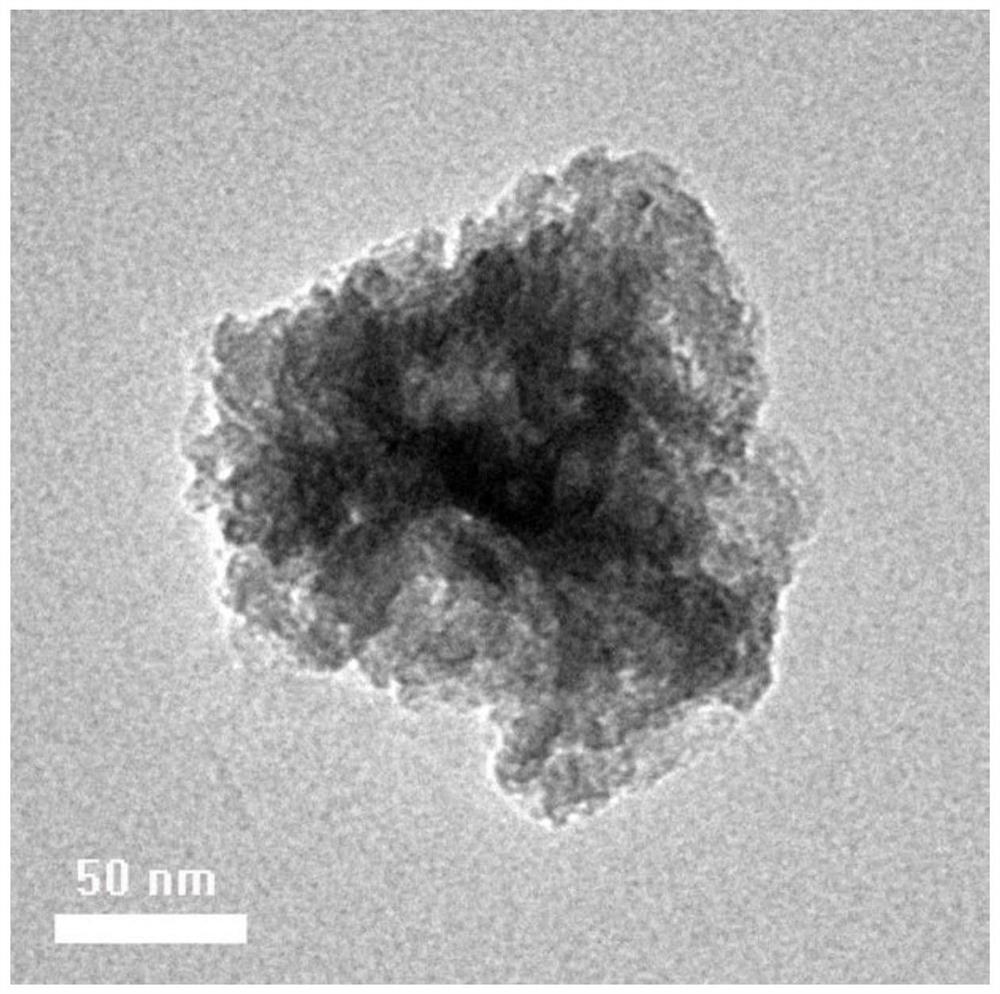

Image

Examples

Embodiment 1

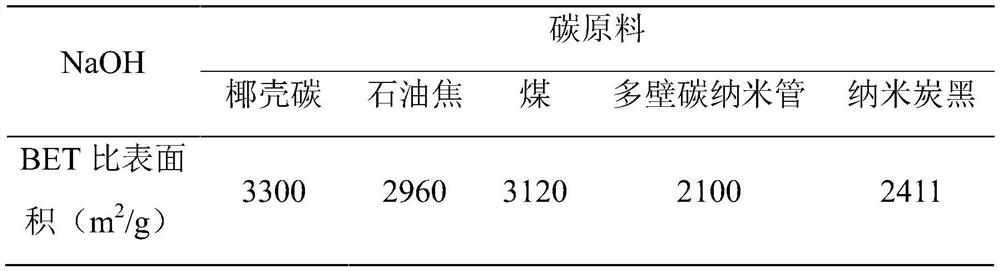

[0051] The pre-carbonized coconut shell carbon, petroleum coke, coal, multi-walled carbon nanotubes and nano-carbon black were treated with 25% hydrogen peroxide, and then impregnated with 50% NaOH aqueous solution to obtain a solid sample with a NaOH loading of 20%. Take 100 grams of sample and process it in a microwave reactor with microwave irradiation with a frequency of 1.2 GHz for 8 minutes, and the nitrogen flow rate during the process is 200 mL / min. The cooled sample was mixed and eluted three times with 1.0 kg of deionized water, and the treatment time was 30 minutes in ultrasonic cleaning each time, and the solid sample was filtered and dried. The porosity properties of the samples were determined by nitrogen adsorption and desorption isotherms. The specific experimental results are shown in Table 1.

[0052] Table 1 Porosity characteristic test result of sample

[0053]

Embodiment 2

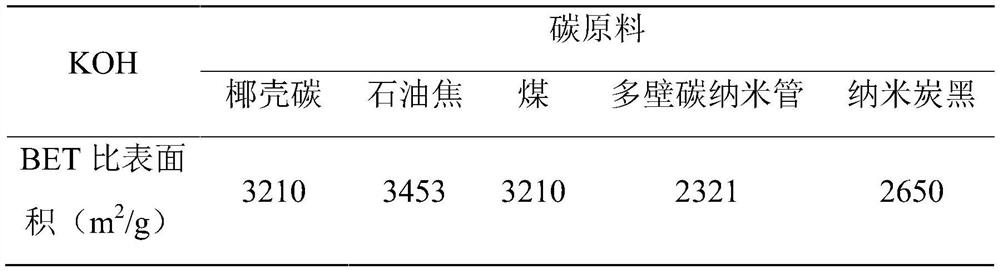

[0055] The pre-carbonized coconut shell carbon, petroleum coke, coal, multi-walled carbon nanotubes and nano-carbon black were treated with 25% hydrogen peroxide and impregnated with 50% KOH aqueous solution to obtain a solid sample with a KOH loading of 20%. Take 100 grams of sample and process it in a microwave reactor with microwave irradiation with a frequency of 1.2 GHz for 8 minutes, and the nitrogen flow rate during the process is 200 mL / min. The cooled sample was mixed and eluted three times with 1.0 kg of deionized water, and the treatment time was 30 minutes in ultrasonic cleaning each time, and the solid sample was filtered and dried. The porosity properties of the samples were determined by nitrogen adsorption and desorption isotherms. The specific experimental results are shown in Table 2.

[0056] Table 2 Porosity characteristic test result of sample

[0057]

Embodiment 3

[0059] Pre-carbonized coconut shell carbon, petroleum coke, coal, multi-walled carbon nanotubes and nano-carbon black are treated with 25% hydrogen peroxide, and then impregnated with 50% NaOH / KOH (mass ratio 1:1) aqueous solution to obtain NaOH / KOH A solid sample with a loading of 20%. Take 100 grams of sample and process it in a microwave reactor with microwave irradiation with a frequency of 1.2 GHz for 8 minutes, and the nitrogen flow rate during the process is 200 mL / min. The cooled sample was mixed and eluted three times with 1.0 kg of deionized water, and the treatment time was 30 minutes in ultrasonic cleaning each time, and the solid sample was filtered and dried. The porosity properties of the samples were determined by nitrogen adsorption and desorption isotherms. The specific experimental results are shown in Table 3.

[0060] The porosity characteristic measurement result of table 3 sample

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com