Feeding device of furniture production cutting machine

A technology of feeding device and cutting machine, applied in sawing equipment, manufacturing tools, wood processing utensils and other directions, can solve problems such as insufficient precision, edge collapse, work injury, etc., to reduce the possibility of injury, improve cutting accuracy, The effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

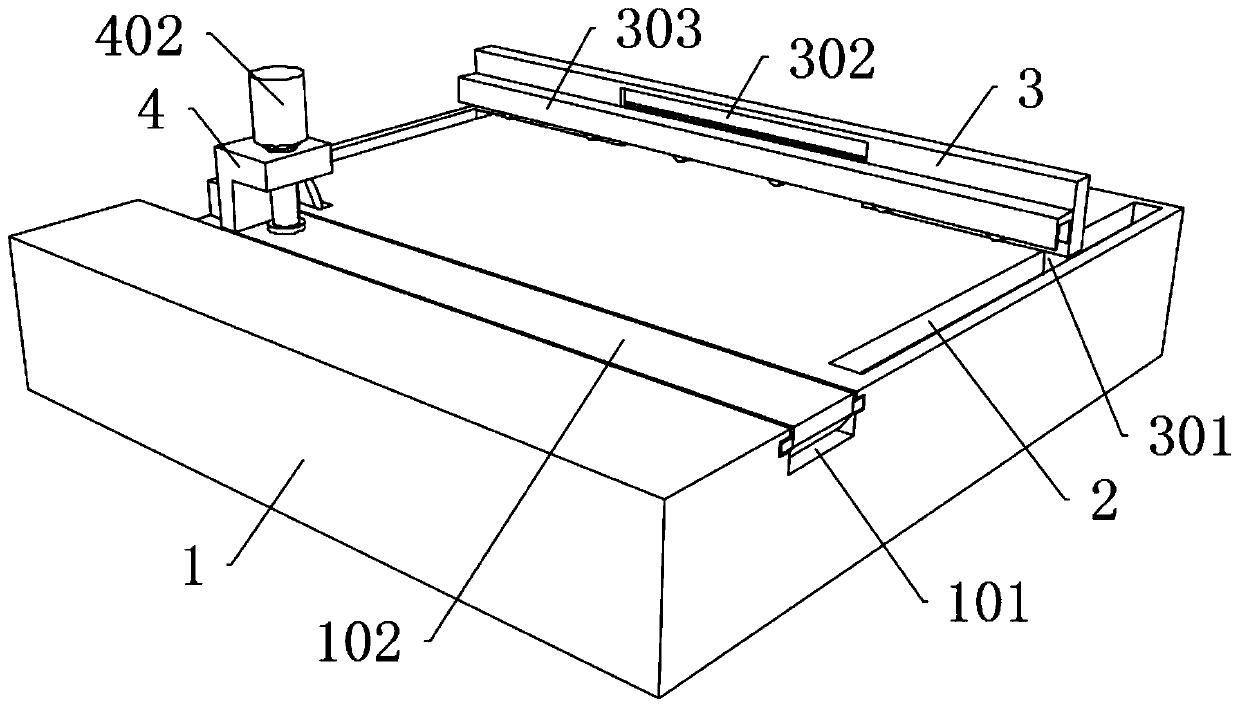

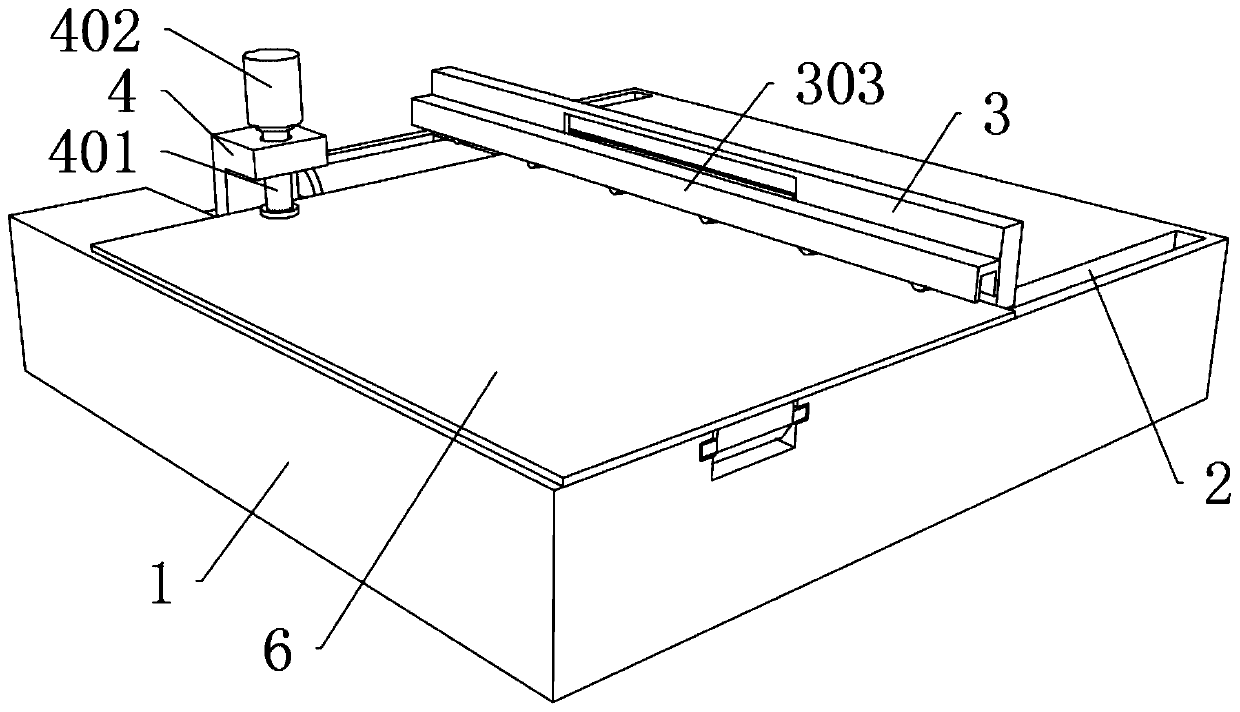

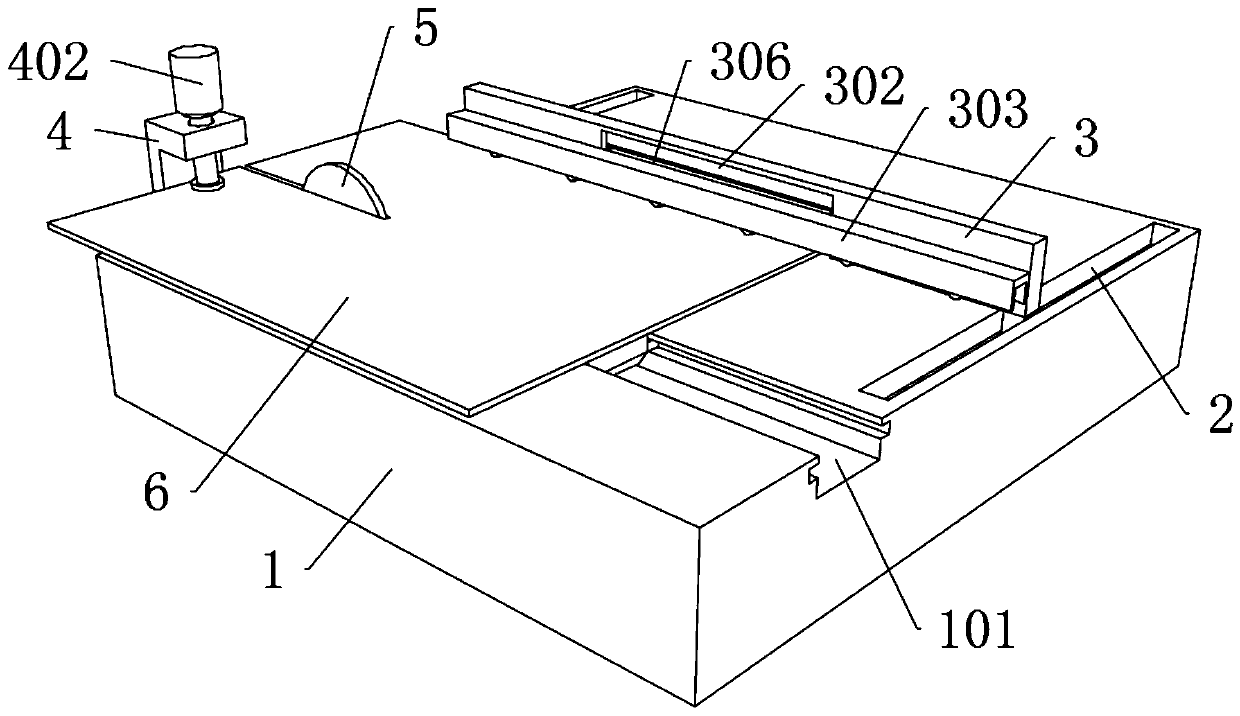

[0039] A feeding device for a cutting machine for furniture production, comprising a cutting machine body 1, a cutting hob 5 is rotatably connected to the upper end of the cutting machine body 1, and the wood placed on the upper end of the cutting machine body 1 can be cut by the cutting hob 5. Cut into small pieces of the required size, the left and right ends of the cutting machine body 1 are dug with slideways 2, the upper end of the cutting machine body 1 is provided with a wood limit bar 3, and the left and right ends of the wood limit bar 3 are fixedly connected with Slider 301, slider 301 and slideway 2 match each other, please refer to image 3 A groove 101 is excavated at the upper end of the cutting machine body 1, a T-shaped groove 302 is excavated at the end of the wood limit bar 3 near the groove 101, and an auxiliary positioning block 303 is provided at the end of the wood limit bar 3 close to the groove 101. The positioning block 303 is fixedly connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com