Intelligent and efficient ore drawing and truck loading integrated control system for blockage-free safety ore bin

A centralized control system, non-blocking technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve problems such as uneven discharge, rollover, vehicle damage, etc., to achieve uniform loading and uniform feeding distribution. , the effect of avoiding vehicle toppling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

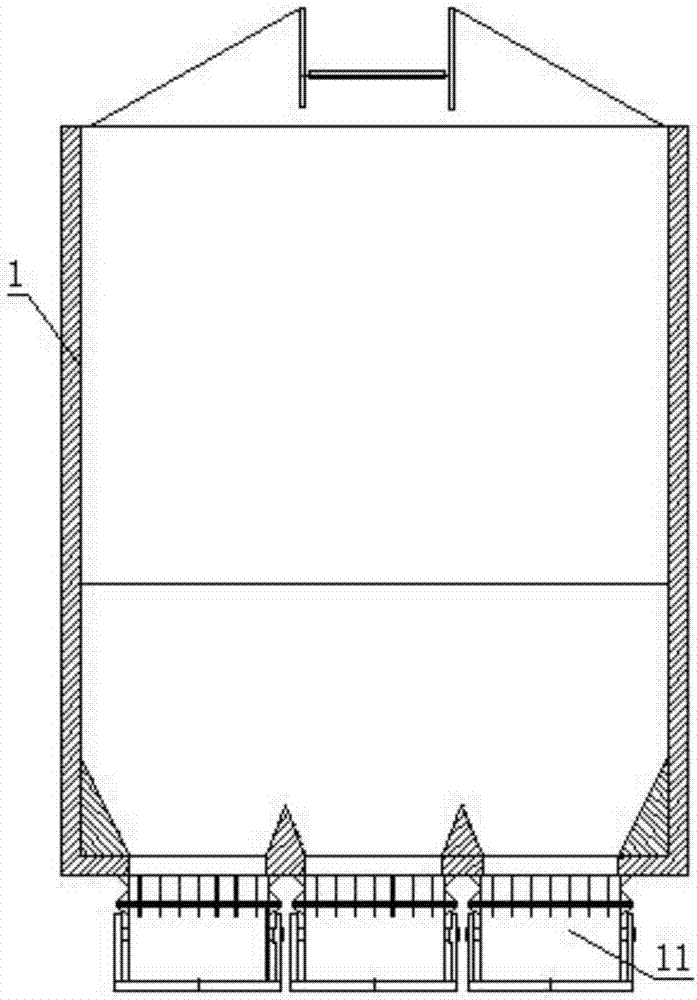

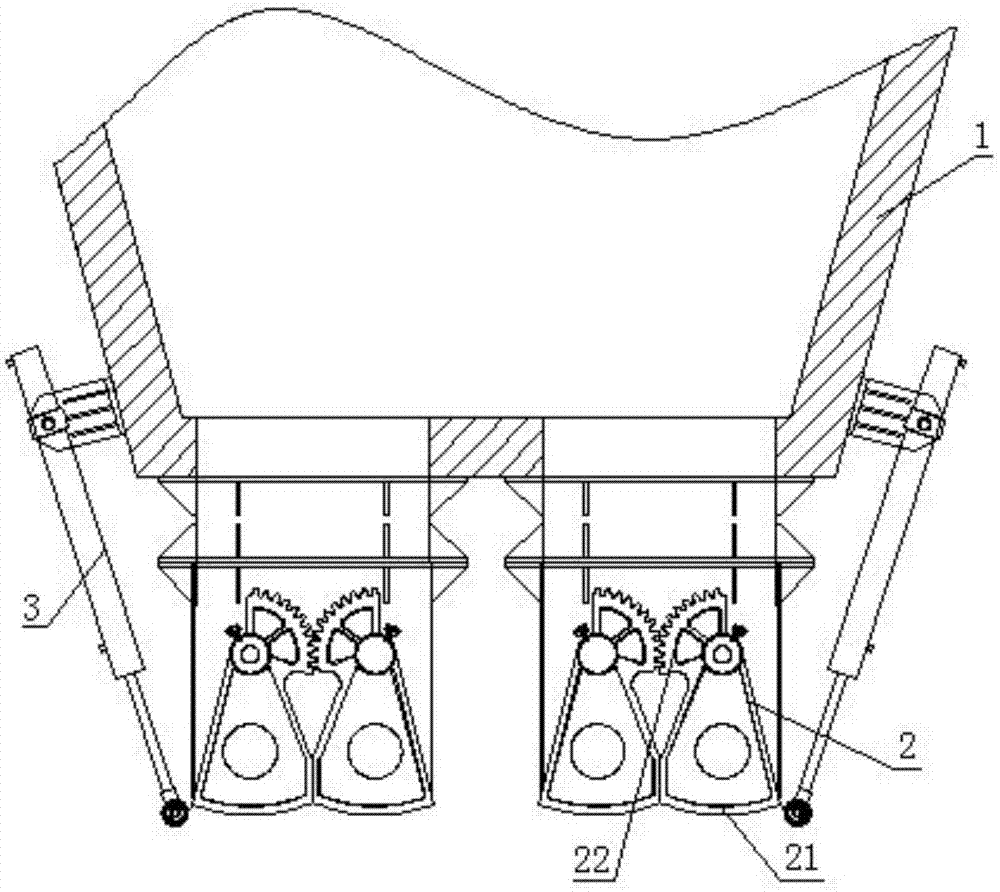

[0034] The non-clogging safe mining bin intelligent and efficient ore-drawing and loading centralized control system includes the mining bin 1 and the control system for controlling the opening and closing of the mining bin 1. The bottom of the mining bin 1 is provided with a number of discharge ports 11, and the discharge port 11 is equipped with Jaw-type ore-drawing valve 2, the bottom of ore bin 1 is hinged with hydraulic cylinder 3, hydraulic cylinder 3 is connected with hydraulic control system through pipeline, the piston rod of hydraulic cylinder 3 is hinged with the other end of jaw-type ore-drawing valve 2; hydraulic cylinder 3 There is an electromagnetic reversing valve connected to it, and the control system includes an industrial computer. The industrial computer is connected with a PLC controller. The control module is electrically connected.

[0035] The present invention has a plurality of discharge ports 11, and through the staggered control module to control m...

Embodiment 2

[0037]On the basis of Embodiment 1, the jaw-type ore-drawing valve 2 includes two sets of rotating valve plates 21, both of which are hinged with the mine bin 1, and the rotating valve plates 21 are connected with gears 22, and the two sets of rotating valve plates The gear 22 on the plate 21 meshes, and the end of one group of rotating valve plates 21 away from the gear 22 is hinged with the piston rod of the hydraulic cylinder 3 .

[0038] When the control system drives the hydraulic cylinder 3 to act, the two groups of rotating valve plates 21 rotate oppositely under the condition that the two groups of gears 22 mesh with each other, and the discharge port 11 is opened. The elongation of the hydraulic cylinder 3 is controlled by controlling the action time of the hydraulic cylinder 3 , thereby controlling the opening and closing degree of the discharge port 11 . The jaw-type ore-drawing valve 2 can ensure the accurate opening and closing of the discharge port 11, and the op...

Embodiment 3

[0040] On the basis of any one of the above embodiments, the interleaved control module includes a time relay, the time relay is electrically connected to the PLC controller, the normally open contact of the time relay is electrically connected to the first switch, and the normally closed contact of the time relay The point is electrically connected to a second switch; the positive travel joints of several electromagnetic reversing valves are connected to a full warehouse control module, the output end of the first switch is electrically connected to a part of the full warehouse control module, and the second switch is connected to the other part of the full warehouse control module. Electrical connection; the full warehouse control module is electrically connected to the PLC controller to form a feedback circuit, the reverse travel joint of the electromagnetic reversing valve is electrically connected to the PLC controller, and the closing time of the time relay is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com