Air inflating tool for protecting welded back surface of stainless steel plate

A backside protection, stainless steel plate technology, applied in the direction of providing/removing protective gas, welding accessories, etc., can solve the problems of poor protection, excessive gas rejection, gas turbulence, etc., to achieve good protection effect and replacement speed. The effect of speeding up and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

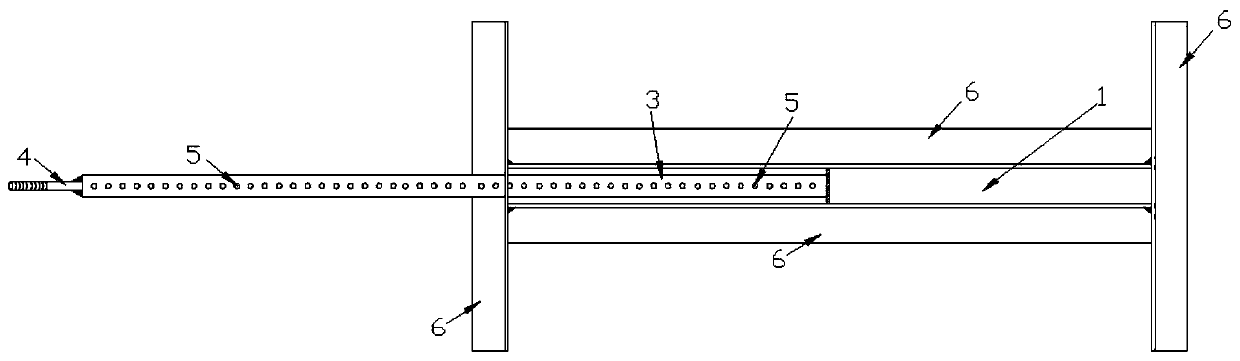

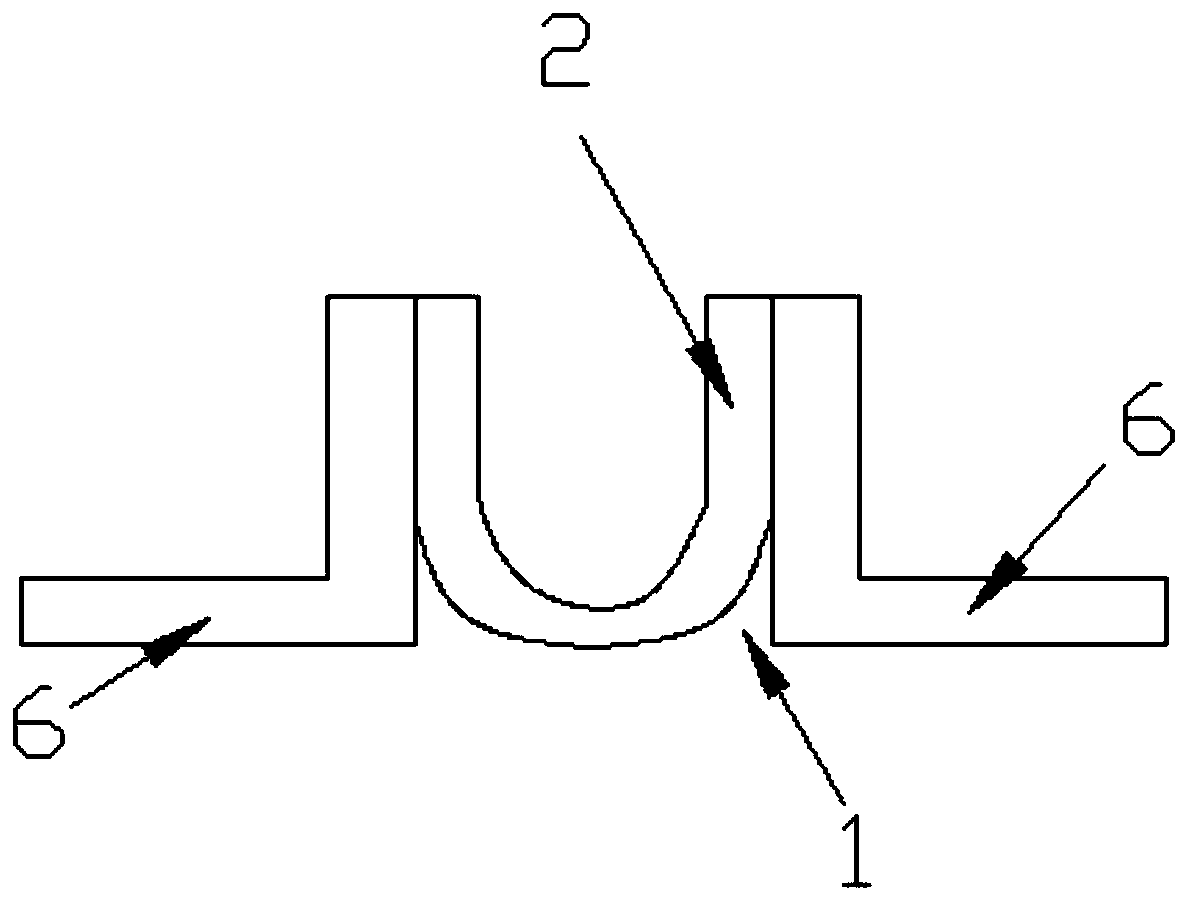

[0023] Such as figure 1 , figure 2 As shown, the present invention is a protective inflatable tool for welding the back of a stainless steel plate, including a back protection inflatable tank 1 arranged in cooperation with the welding seam on the back side, and a V-shaped or U-shaped inflatable protective cover 2 is arranged in the back protection inflatable tank 1. A diffusion buffer 3 is slidably arranged in the inflatable protective cover 2 , and an end of the diffusion buffer 3 located outside the back protection inflation tank 1 is provided with a protective gas pipe joint 4 . Diffusion buffer 3 is a copper pipe with a row of argon gas inlet holes 5 on the surface. Air inlet holes 5 are arranged along the length direction of the copper pipe. The angle steel 6 is welded and fixed, and the four angle steels 6 are fixedly arranged on the backing floor, and the two longitudinal angle steels 6 are respectively arranged on both sides of the copper pipe, and one of the horizon...

Embodiment 2

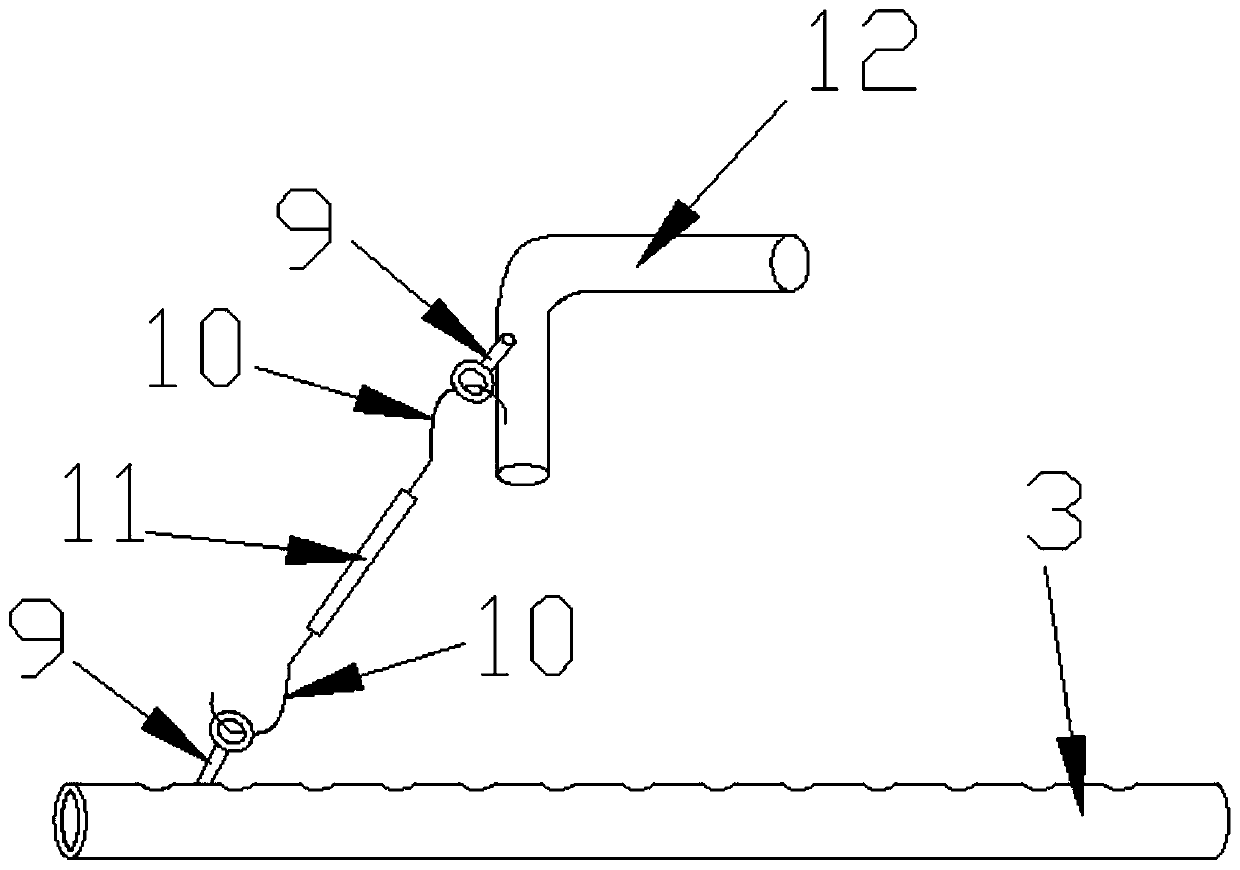

[0030] The difference from Embodiment 1 is that, as image 3 As shown, the diffusion buffer 3 is fixedly provided with a connecting ring 9, and a connecting rod 11 with a hook 10 is arranged to match the connecting ring 9, and a hook 10 is provided at both ends of the connecting rod 11, one of which is connected to the connecting ring 9 The other one cooperates with the connecting ring 9 fixedly arranged on the welding equipment 12 .

Embodiment 3

[0032] The difference from Embodiment 1 is that, as Figure 4 to Figure 8 shown (for ease of illustration, Figure 7 , Figure 8 Only one adjustment line is shown in the figure), and the part of the diffusion buffer 3 located outside the back protection air tank 1 is covered with an air shielding sleeve 7 . The air-blocking sleeve 7 is tubular made of plastic film material, and the two pipe ends of the air-blocking sleeve 7 are fixed with elastic rubber sealing rings 8, and the length of the air-blocking sleeve 7 is equivalent to the length of the copper pipe; the diffusion buffer 3 A sealing rubber plate 13 is fixed at one end of the back protection inflatable groove 1, and a sealing rubber strip 14 is fixedly installed on the edge of the angle steel 6 facing the part to be welded; the sealing rubber plate 13 is provided with one or two exhaust holes 15 . A baffle plate 16 for adjusting the size of the exhaust hole 15 is hinged on the sealing rubber plate 13 , and an adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com