Component-adjustable inorganic perovskite photoelectric thin film and low-temperature preparation method and device application thereof

A technology of photoelectric thin film and inorganic calcium, which is applied in the field of controllable preparation and devices of new semiconductor photoelectric materials, can solve the problems of poor photoelectric performance, low solubility, and reduced conductivity of perovskite materials, and achieve precise and adjustable halogen ratio, optical The effect of adjustable bandgap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The transparent conductive substrate (ITO / FTO) was ultrasonically cleaned with deionized water, acetone, and isopropanol, respectively, and ultrasonically oscillated in the respective solutions for 15 minutes.

[0049] The above cleaned substrates were washed with N 2 Blow dry for use, and use ultraviolet ozone to clean the surface of the transparent conductive substrate for 20 minutes.

[0050] Preparation of cesium lead bromine perovskite thin film: 0.4 mol of cesium bromide and 0.4 mol of lead bromide were dissolved in 1 mL of DMSO solution, followed by heating and stirring for 12 hours at a heating temperature of 70°C.

[0051] The prepared precursor solution was spin-coated on the FTO substrate. The spin-coating conditions were: 500 rpm for 6 seconds, and 5000 rpm for 30 seconds; then it was annealed at 100 °C in a nitrogen atmosphere for 10 minutes.

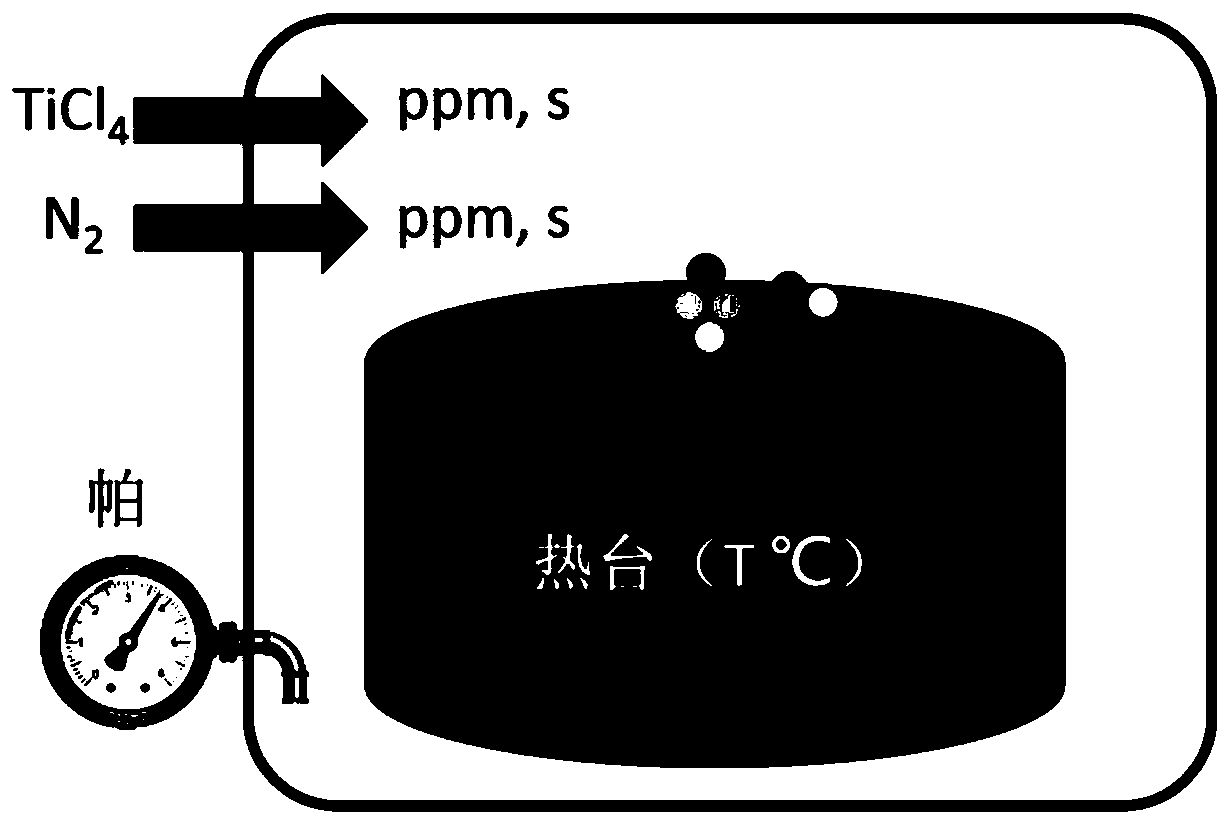

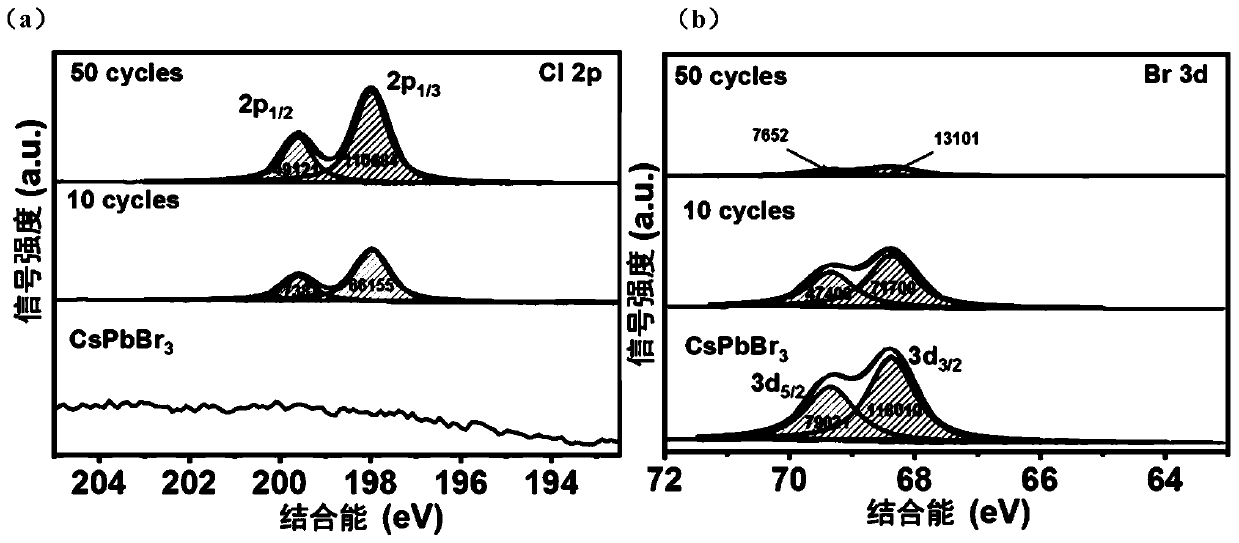

[0052] Finally, TiCl was purged on the spin-coated perovskite substrate by atomic layer deposition 4 , the depos...

Embodiment 2

[0056] The flexible conductive substrates (such as PET / ITO) were ultrasonically cleaned with deionized water, acetone, and isopropanol, respectively, and ultrasonically cleaned in the respective solutions for 15 min.

[0057] The above cleaned substrate was blown dry with nitrogen, and treated with ultraviolet ozone for 20 minutes.

[0058] The inorganic perovskite precursor solution prepared in Example 1 was spin-coated on the flexible ITO substrate. The spin-coating conditions were: 6 seconds at a rotation speed of 500 rpm, and then 30 seconds at a rotation speed of 5000 rpm; then it was annealed at 100 ° C under a nitrogen atmosphere treatment, the annealing time is 10min.

[0059] Finally, TiCl was purged on the spin-coated perovskite substrate by atomic layer deposition 4 , the deposition conditions are: precursor source selection (titanium tetrachloride, TiCl 4 ), TiCl 4 The time to enter the pipeline is 500ms, the cavity temperature is set at 105°C, 1-100 cycles, the...

Embodiment 3

[0060] Embodiment 3 The making of photodetection device

[0061] Use deionized water, acetone, and isopropanol to ultrasonically clean the hard substrate or flexible conductive substrate (such as PET / ITO), respectively, and ultrasonically clean them in their respective solutions for 15 minutes.

[0062] The above cleaned substrate was blown dry with nitrogen, and treated with ultraviolet ozone for 20 minutes.

[0063] Deposit a layer of titanium oxide on the above treated substrate by atomic layer deposition technology, deposition conditions: chamber temperature 105°C, time for titanium tetrachloride to flow into the pipeline is 200ms, purge for 2 seconds, time for water to flow into the pipeline is 500ms, purge for 4 seconds, and the number of cycles is set to 170 cycles.

[0064] The inorganic perovskite precursor solution prepared in Example 1 was spin-coated on the above-mentioned substrate, and the spin-coating conditions were: 6 seconds at a rotation speed of 500 rpm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com