Evaporation process discharge caustic alkali concentration measurement device accuracy compensation method

A concentration measurement and precision compensation technology, applied in measurement devices, neural learning methods, analytical materials, etc., can solve the problems of fluctuation of raw ore composition, drift of output value of online measurement devices, and high price of online instruments, so as to reduce production costs and improve measurement efficiency. Satisfactory accuracy and stable alumina production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

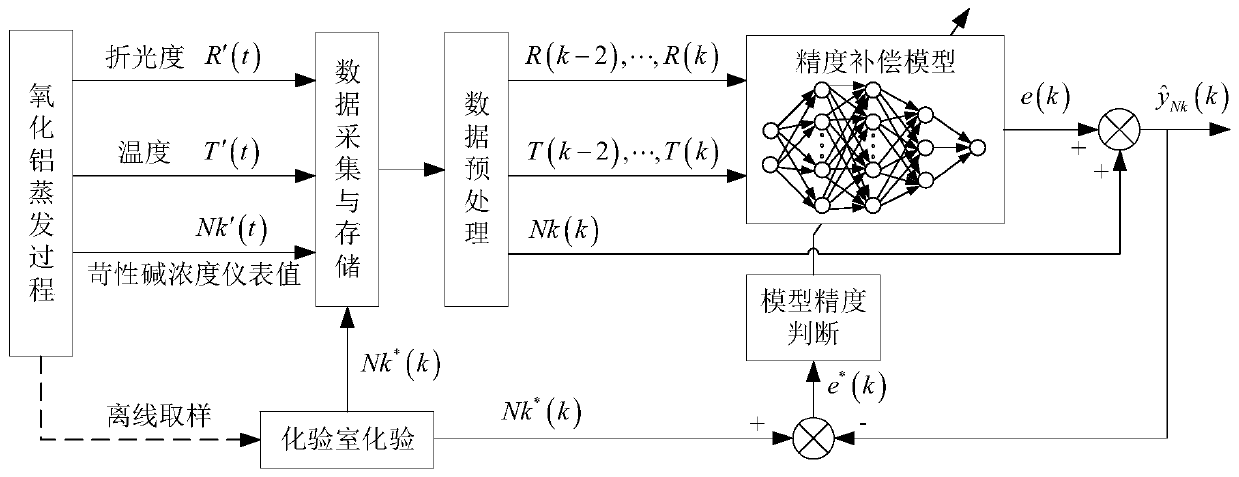

[0047] This embodiment discloses a method for compensating the accuracy of a caustic concentration measuring device for discharge during an evaporation process, which includes the following steps:

[0048] Step 1: Data collection: collect the process data of lye refraction, temperature, caustic concentration instrument value and laboratory value during the evaporation process;

[0049] Step 2: Data preprocessing: Perform moving average filter processing, timing matching, and normalization processing on the process data collected in step 1 to obtain preprocessed process data;

[0050] Step 3: Input the preprocessed process data into the accuracy compensation model of the caustic concentration measuring device to obtain the compensation value;

[0051] Step 4: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com