Oak barrel liquor clarification method and clarification device thereof and oak barrel liquor production method and production system

A production method and technology of a production system, applied in the field of liquor production, can solve the problems of less flavor substances, damage to the flavor of oak barrel liquor, weak aroma, etc., achieve high filtration accuracy, improve freezing resistance and low temperature stability, and have large filtration flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A. Filter device installation:

[0030] A1. Place the polymer filter sheet 10 with a thickness of 20mm and a pore size of 0.13um in oak barrel white wine to be filtered for 1h;

[0031] A2, the polymer filter sheet 10 is installed in the polymer filter device 4, and then the upper end and the lower end of the polymer filter device 4 are connected through the quick release connection ring 9;

[0032] A3. Install an externally pressured polyvinylidene fluoride roll-type membrane with a cut-off molecular weight of 250,000 Daltons in the membrane filtration device 14 .

[0033] B. Filtering:

[0034] B1, at room temperature, inject a certain volume of oak barrel liquor to be filtered into the liquid storage container 1;

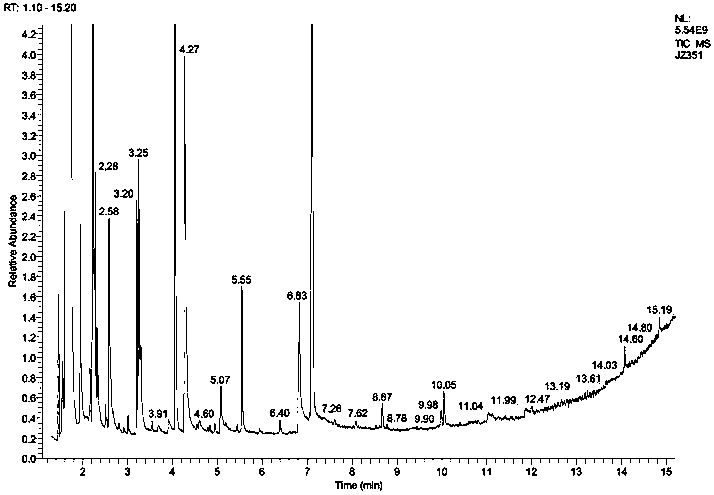

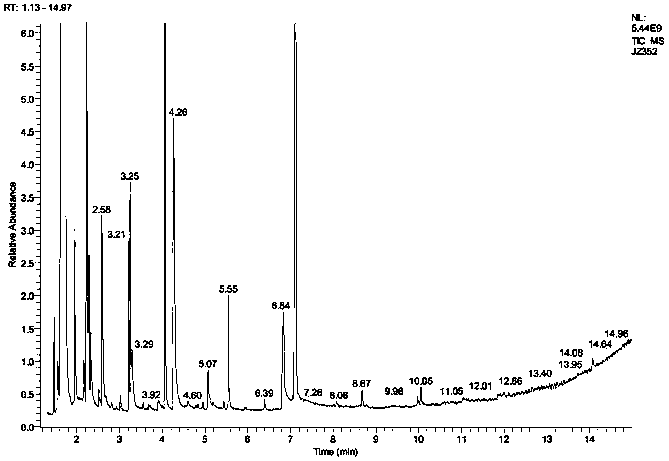

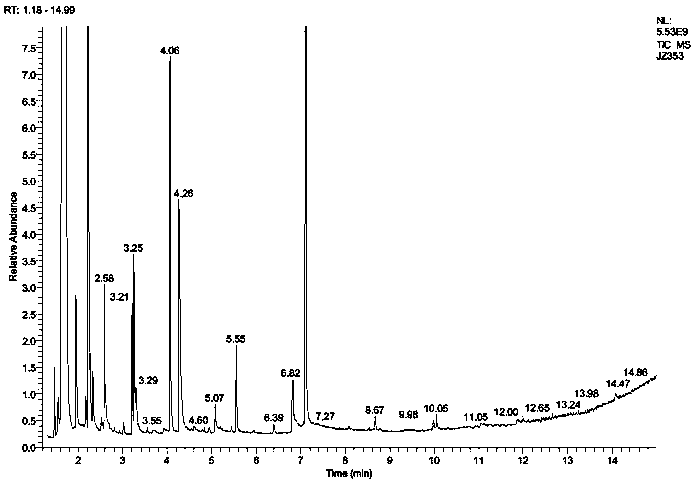

[0035]B2, open all valves, then turn on the power switch, the oak barrel liquor to be filtered enters the polymer filter device 4 and the membrane filter device 14 successively from the liquid storage container 1, and enters the membrane after being filt...

Embodiment 2

[0045] A. Filter device installation:

[0046] A1, the polymer filter sheet 10 with a thickness of 15mm and a pore size of 0.10um is placed in oak barrel white wine to be filtered (batch is the same as that of Example 1) and soaked for 1h;

[0047] A2, the polymer filter sheet 10 is installed in the polymer filter device 4, and then the upper end and the lower end of the polymer filter device 4 are connected through the quick release connection ring 9;

[0048] A3. Install an externally pressured polyvinylidene fluoride roll-type membrane with a cut-off molecular weight of 280,000 Daltons in the membrane filtration device 14 .

[0049] B. Filtering:

[0050] B1, at room temperature, inject a certain volume of oak barrel liquor to be filtered into the liquid storage container 1;

[0051] B2, open all valves, then turn on the power switch, the oak barrel white wine to be filtered (batch is identical with embodiment 1) enters polymer filter device 4 and membrane filter device 1...

Embodiment 3

[0061] A. Filter device installation:

[0062] A1, the polymer filter sheet 10 with a thickness of 25mm and a pore size of 0.20um is placed in the oak barrel white wine to be filtered (batch is the same as that of Example 1) and soaked for 1h;

[0063] A2, the polymer filter sheet 10 is installed in the polymer filter device 4, and then the upper end and the lower end of the polymer filter device 4 are connected through the quick release connection ring 9;

[0064] A3. Install an externally pressured polyvinylidene fluoride roll-type membrane with a molecular weight cut-off of 300,000 Daltons in the membrane filtration device 14 .

[0065] B. Filtering:

[0066] B1, at room temperature, inject a certain volume of oak barrel liquor to be filtered into the liquid storage container 1;

[0067] B2, open all valves, then turn on the power switch, the oak barrel white wine to be filtered (batch is identical with embodiment 1) enters polymer filter device 4 and membrane filter devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com