A non-toxic, harmless, high-strength, high-heat-resistant hemicellulose foam composite material and its preparation method

A hemicellulose, non-toxic and harmless technology, applied in the field of non-toxic, harmless, high-strength and high heat-resistant hemicellulose foam composite materials and its preparation, can solve the problem that foam composite materials are not suitable for human soft tissue engineering and limit human soft tissue Engineering development, poor mechanical strength and other problems, to achieve the effect of easy control of reaction conditions, great application potential and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

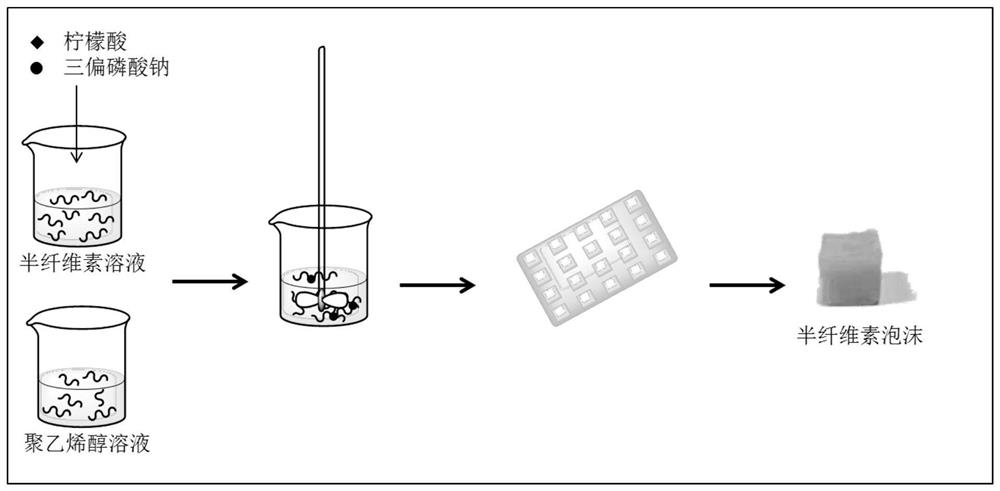

[0030] Preparation of a non-toxic, harmless, high-strength, high-heat-resistant hemicellulose foam composite material (see attached figure 1 ), including the following steps:

[0031] (1) Add 1.0 g of xylan hemicellulose, 5 g of citric acid, and 10 g of sodium trimetaphosphate into deionized water, stir and dissolve at 90° C. for 5 hours, and obtain a mixed solution with a concentration of xylan hemicellulose of 1 wt %;

[0032] (2) Add 5.0 g of polyvinyl alcohol into deionized water, stir and dissolve at 90°C for 1 hour to obtain a polyvinyl alcohol solution;

[0033] (3) Mix the mixed solution of step (1) with the polyvinyl alcohol solution of step (2) and stir for 30s at a stirring rate of 700 r / min, pour the obtained cross-linked product into the mold, and wash the surface of the foam with deionized water after cooling and forming 5 times, after drying at room temperature for 5 days, a hemicellulose foam with high strength and high heat resistance was obtained.

[0034] ...

Embodiment 2

[0037] The preparation of a non-toxic, harmless, high-strength and high-heat-resistant hemicellulose foam composite material comprises the following steps:

[0038] (1) Add 2.0 g of xylan hemicellulose, 5 g of citric acid, and 10 g of sodium trimetaphosphate into deionized water, stir and dissolve at 80° C. for 4 hours, and obtain a mixed solution with a concentration of xylan hemicellulose of 2 wt %;

[0039] (2) Add 5.0g polyvinyl alcohol into deionized water, stir and dissolve at 80°C for 1.5h to obtain a polyvinyl alcohol solution;

[0040] (3) Mix the mixed solution of step (1) with the polyvinyl alcohol solution of step (2) and stir for 30s at a stirring rate of 600 r / min, pour the obtained cross-linked product into the mold, and wash the surface of the foam with deionized water after cooling and forming 4 times, after drying at room temperature for 4 days, a hemicellulose foam with high strength and high heat resistance was obtained.

[0041] The obtained hemicellulose...

Embodiment 3

[0044] The preparation of a non-toxic, harmless, high-strength and high-heat-resistant hemicellulose foam composite material comprises the following steps:

[0045] (1) Add 3.0 g of xylan hemicellulose, 5 g of citric acid, and 10 g of sodium trimetaphosphate into deionized water, stir and dissolve at 70° C. for 3 hours, and obtain a mixed solution with a concentration of xylan hemicellulose of 3 wt %;

[0046] (2) Add 5.0 g of polyvinyl alcohol into deionized water, stir and dissolve at 70°C for 2 hours to obtain a polyvinyl alcohol solution;

[0047] (3) Mix the mixed solution of step (1) with the polyvinyl alcohol solution of step (2) and stir for 30s at a stirring rate of 500 r / min, pour the obtained cross-linked product into the mold, and wash the surface of the foam with deionized water after cooling and forming 3 times, after drying at room temperature for 3 days, a hemicellulose foam with high strength and high heat resistance was obtained.

[0048] The obtained hemice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com