Method for removing metal ions in organic silicon

A metal ion and organosilicon technology, applied in the fields of silicon organic compounds, fractionation, distillation adjustment/control, etc., can solve the problems of difficult removal of metal ions and high removal cost, and achieve uniform heating, fast evaporation rate, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

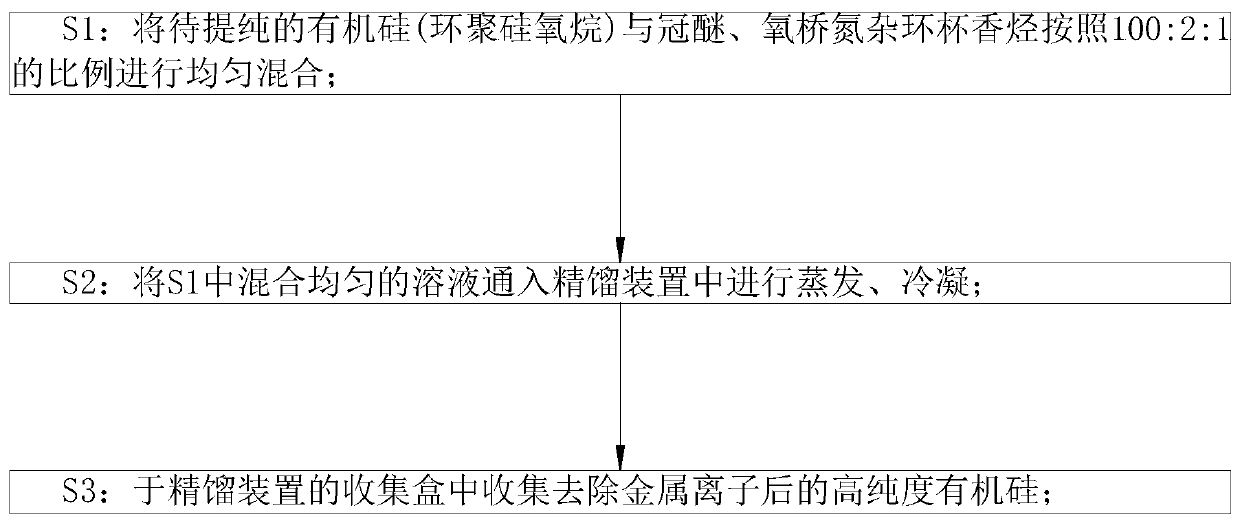

Method used

Image

Examples

Embodiment approach

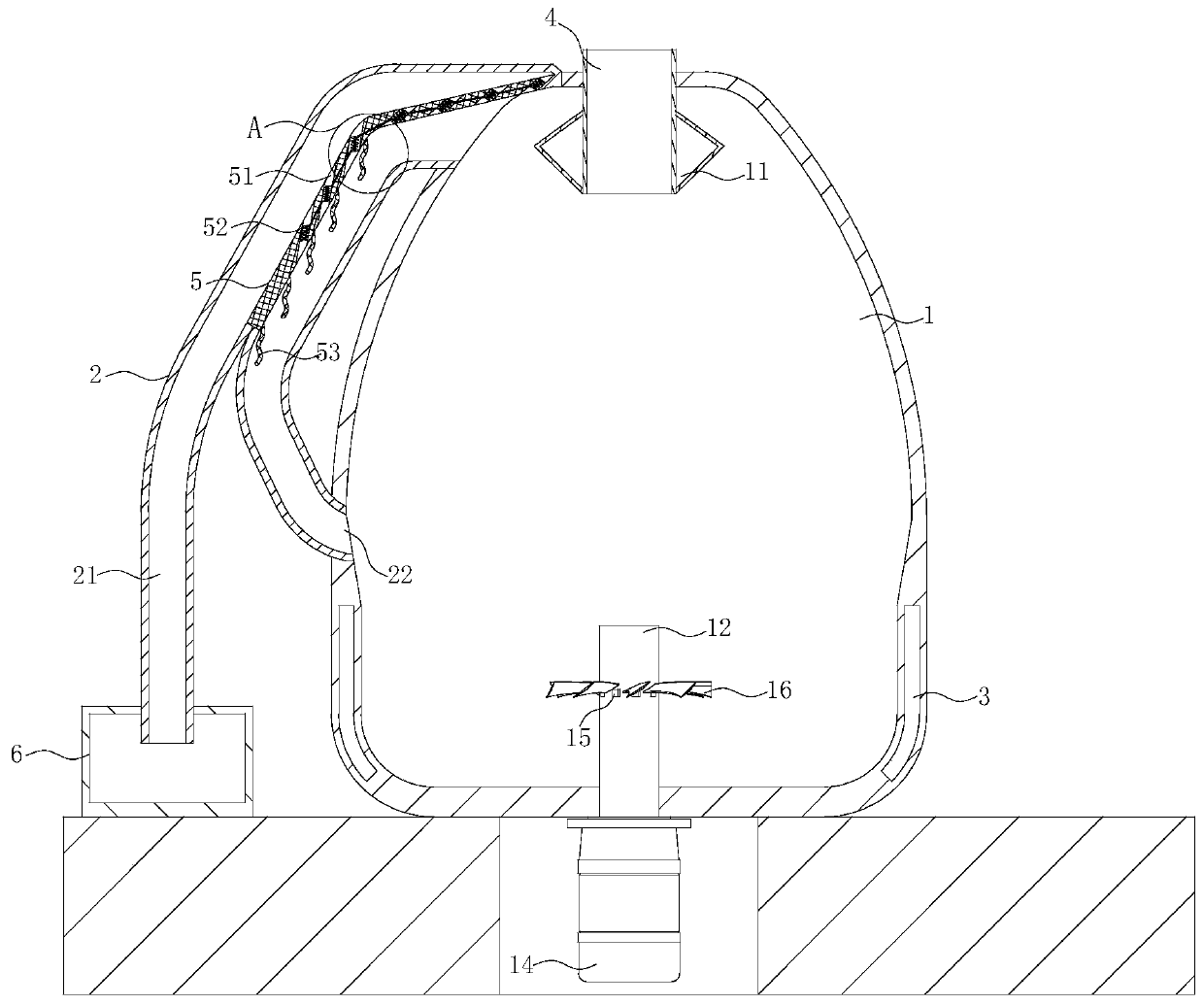

[0032] As an embodiment of the present invention, a stirring shaft 12 is rotatably connected to the bottom of the inner cavity of the rectifying tank body 1; a first cavity 13 is opened inside the stirring shaft 12; the bottom of the rectifying tank body 1 is fixedly connected to There is an air pump 14; the air outlet of the air pump 14 runs through the rectification tank 1 and communicates with the first cavity 13; the surface of the stirring shaft 12 is provided with uniformly arranged air injection ports 15; the air injection ports 15 are connected to the first cavity 13 A cavity 13 is connected; when working, the air pump 14 is energized first, so that the air outlet on the stirring shaft 12 continuously ejects cold air, and then the mixed solution is passed into the rectification tank 1, and the stirring shaft 12 The ejected airflow can further stir the mixed solution, so that the components in the mixed solution can be mixed more evenly. At the same time, when the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com